- Home > Product > Electric Drive > Low Voltage Drives > AC310 Series Variable Frequency Drive - AC Drive

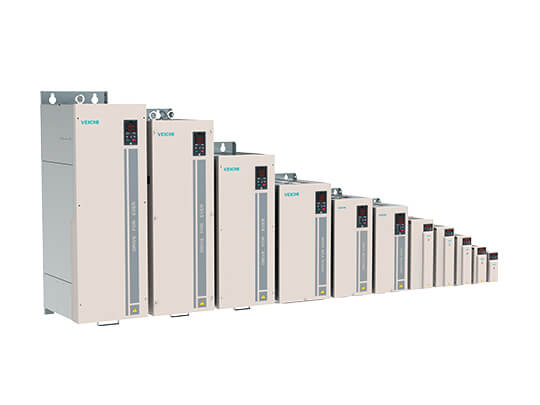

AC310 Series Variable Frequency Drive - AC Drive

- AC310 series AC drive adopts magnetic field oriented vector control technology compatible with synchronous and asynchronous motor control.

- Under the premise of high performance and high reliability, the components are reasonably laid out to realize the book-type narrow body design, saving the installation space.

- Strengthen the customer's ease of use and industry professional design, equipped with a wealth of expansion interfaces, and new expansion accessories.

- High performance, high reliability, high power density, high applicability.

- Satisfy the STO safety function in accordance with SIL3.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

AC310 series high-performance ac drive overview

VEICHI AC310 series AC drive is a high-performance vector controller that is a continuation of the AC300 hardware structure design concept by VEICHI, retains the characteristics of the new generation of VEICHI products, and breaks through innovation in functional performance. It not only adopts the international leading field-oriented vector control technology, but also enriches the control methods of various forms of load such as voltage-frequency separation EPS power supply on the basis of compatible asynchronous and synchronous motor control. Under the premise of ensuring product high performance and high reliability, rationally layout parts, maintain product book-style narrow body design, pay attention to product ease of use and industry-specific design, and better solve customers' product selection troubles. It is equipped with abundant expansion ports and a variety of expansion accessories to achieve the characteristics of high performance, high reliability, high power density and high applicability.

Product features

1. High-performance vector universal platform and brand new motor control algorithm.

2. Synchronous and asynchronous drives are integrated, open-loop and closed-loop are comprehensive.

3. Accurate torque excitation decoupling and excellent dynamic response performance.

4. The entire series of book-based design saves installation space to the greatest extent.

5. Comprehensive thermal simulation design to ensure the rationality of hardware arrangement.

6. AC310 series innovative grounding method can quickly solve the problem of electromagnetic interference.

7. Software and hardware modular design requirements and powerful expansion capabilities.

8. PCB is properly sprayed with three anti-paints to improve product environmental adaptability.

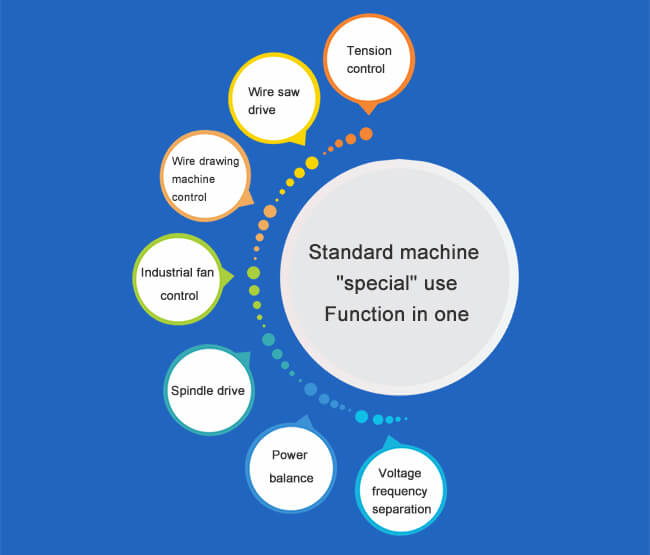

Standard machine "special" use and function in one

AC310 continues the innovative mechanism of the AC300 series, retains the original product features, and it is committed to solving customers' troubles in selecting models and improving market competitiveness. It has the function of industry expansion, which can be expanded and increased according to the actual use of industry parameters, and integrates multiple industry parameters, so as to realize the "special" use of the standard machine and the integration of functions.

Actively respond to Industry 4.0

With the continuous reform of intelligent production, centralized control of products becomes more common.AC310 products can support different types of DCS systems and PLC systems to achieve commonality, it can also support various types of touch screen and AC310 direct communication, standard MODBUS-RTU communication, compatible and optional support PROFIBUS-DP, CANOPEN, PROFINET communication protocol.

Perfect protection mechanism

It has hardware protection functions such as output short-circuit protection to ground, internal buffer relay protection, fan drive circuit protection, external 24VDC short-circuit protection, motor overload protection, and other hardware protection functions. It can realize all-around protection of the internal and peripheral equipment of the drive.

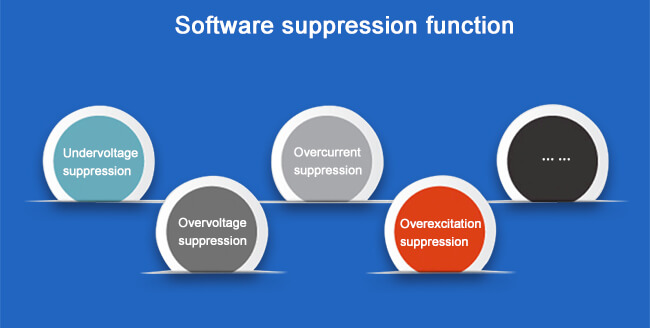

Software suppression function

1. Undervoltage suppression

2. Overvoltage suppression

3. Overcurrent suppression

4. Overexcitation suppression

Unique ingenuity and bringing brilliant control algorithms

1. Drive a variety of loads: support synchronous, asynchronous, synchronous reluctance motors, electric spindles, AC servos, and other motors.

2. Comprehensive control modes: one machine covers V/F mode, separation of voltage and frequency, open/closed-loop vector, free choice of speed, and torque.

3. Motor self-learning: the world's leading self-learning algorithm, accurate and consistent movement and static.

4. High-speed field weakening control: high-bandwidth current vector, 12 times the field weakening high-precision output.

New appearance, design and aesthetics are integrated

1. The book-style narrow body design reduces the volume by up to 60%.

2. Up and down straight-through heat dissipation, multiple controllers can be installed side by side, greatly reducing the volume of the electrical cabinet.

3. Brand-new keyboard design, simple appearance, support dual keyboard display.

Make it simple, save more time

1. European-style terminal, simple wiring, improve efficiency.

2. Domestic general parameter arrangement, optimized operation buttons, easy to use.

3. The dedicated upper debugging software VCASoft Ver1.3 can minimize the debugging time and difficulty.

All-in-one, rich and excellent expansion capabilities

1. A variety of extended interfaces to meet the needs of customization.

2. The AC310 control board reserves two SPI high-speed channel external extension cards. The control board automatically recognizes the expansion card and includes the expansion card setting parameter group.

AC310 Series High-performance Variable Frequency Drive - AC Drive Video

Industrial Applications for AC310 Series AC Frequency Drive

Applications: fans and water pumps, air compressors, wire drawing machines, injection molding machines, ball mills, machine tools,industrial washing machines, lifting and other industries and equipments.

Specifications

| Single phase 220V 50/60Hz | 0.75kW - 220kW |

|---|---|

| Three phase 220V 50/60Hz | 0.75kW - 220kW |

| Three phase 380V 50/60Hz | 0.75kW - 1,120kW |

| Voltage and frequency | Single phase :220V 50/60Hz;Three phase: 220V 50/60Hz; Three phase 380V 50/60Hz |

|---|---|

| Allowed fluctuation range | voltage unbalance rate:<3%; Frequency:±5%; aberration rate: as IEC61800-2 required |

| Switching impulse current | Lower than rated current |

| Power factor | ≥0.94(with DC reactor) |

| Frequency drive efficiency | ≥96% |

| Output voltage | Output under rated condition: 3 phase, 0~input voltage, deviation<5% |

|---|---|

| Output frequency range | G type: 0~800Hz |

| Output frequency accuracy | Max frequency ±0.5% |

| Overload capacity | G type: 150% rated current/1 min, 180% rated current/10s, 200% rated current/0.5s P type: 120% rated current/1 min, 140% rated current/10s, 150% rated current/0.5s |

| Motor type | Three-phase asynchronous motor; Permanent magnet synchronous motor (sine wave) |

|---|---|

| Control mode | V/F control, Open loop vector control, Closed loop vector control |

| Carrier frequency | 1.0~16.0kHz |

| Speed control range | VC without PG: rated load 1:1000 |

| Steady speed | VC without PG: ≤2% rated synchronized speed; VC with PG: ≤0.05% rated synchronized speed |

| Starting torque | VC without PG: 150% rated torque at 0.5Hz; VC with PG: 0Hz, 200% rated torque at 0Hz |

| Torque response | VC without PG:<20ms; VC with PG: <10ms |

| Frequency accuracy | Digital setting: max frequency×±0.01%; Analog setting: max frequency×±0.2% |

| Frequency resolution | Digital setting: 0.01Hz; Analog setting: max frequency×0.05 |

| Torque control | Torque setting calculation, torque mode speed limit |

|---|---|

| DC braking capability | Starting frequency:0.00~50.00Hz; Braking time:0.0~60.0s; Braking current:0.0~150.0% rated |

| Torque boost | Automatic torque boost 0.0%~100.0%; Manual torque boost 0.0%~30.0% |

| V/F curve | Four modes: linear torque characteristic curve, self-set V/F curve, torque reduction characteristic curve (1.1 to 2.0 power), square V/F curve |

| Acceleration/Deceler ation curve | 2 modes: linear Acceleration/Deceleration and S curve Acceleration/Deceleration. 4 sets of ACC/DEC, time unit 0.01s selectable, longest time: 650.00s |

| Automatic voltage adjustment | When the voltage fluctuates, the output voltage is automatically maintained |

| Automatic energy-saving operation | Automatically optimize output voltage according to load in V/F control mode to achieve energy-saving operation |

| Rated output voltage | Using the power supply voltage compensation function, the rated voltage of the motor is 100%, which can be set within the range of 50 to 100% (the output cannot exceed the input voltage). |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Voltage | While power supply voltage fluctuates, it can auto-keep constant output voltage |

| Auto energy-saving running | While under V/F control mode, according to load situation, auto-optimize output voltage to save energy |

| Auto-limit current | Auto-limit the current while running to prevent over current break trouble |

| Instant power off | Uninterrupted operation through bus voltage control during instantaneous power loss |

| Standard functions | PID control, speed track, power off restart, jump frequency, upper/lower frequency limit control, program operation, multi- speed, RS485, analog output, frequency impulse output |

| Frequency setting channels | Keyboard digital setting, Analog voltage/current terminal AI1, Analog voltage/current terminal AI2, Communication given and multi-channel terminal selection, Main and auxiliary channel combination, expansion card, supporting different modes switch. |

| Feedback input channel | Voltage/Current Terminal AI1, Voltage/Current Terminal AI12, Communication given, Low-speed pulse input PUL, extension card |

| Running command | Operation panel given, external terminal given, communication given, expansion card given |

| Input command signal | Start, stop, FWD/REV, JOG, multi-step speed, free stop, reset, ACC/DEC time selection, frequency given channel selection, external fault alarm |

| External output signal | 1 relay output, 1 collector output, 1 AO output: 0~10V output or 4~20mA output |

| Protective function | Overvoltage, under-voltage, current limit, over-current, overload, electric thermal relay, overheat, overvoltage stall, data protection, rapid speed protection, input/output phase failure protection. |

|---|

| LED display | Built-in keyboard: single line 5- digital tube display, monitor 1 drive status quantity External keyboard: double line 5- digital tube display, monitor 2 drive status quantities |

|---|---|

| Copy of parameters | Can upload and download the function code information of the frequency drive to achieve fast copy of parameters |

| Status monitor | Output frequency, given frequency, output current, input voltage, output voltage, motor speed, PID feedback, PID given value, module temperature etc. monitor parameters |

| Error alarm | Over-voltage, under-voltage, over-current, short circuit, phase failure, overload, overheat, overvoltage stall, current limit, or Data protection compromised, current fault health, historical fault record. |

| Install place | The altitude is less than 1000 meters, and the derating is more than 1000 meters. The derating is 1% for every 100 meters. No condensation, icing, rain, snow, hail, etc., solar radiation is less than 700W/m2, air pressure 70~106kPa. |

|---|---|

| Temperature and humidity | -10 ~ +50°C, derating can be used above 40 °C, the maximum temperature is 60 °C (no-load operation), 5%~95%RH(no condensation) |

| Vibration | 9~200Hz, 5.9m/s2(0.6g) |

| Storage temperature | -30~+60℃ |

| Installation mode | Wall hanging |

| Protection degree | IP20 |

| Cooling method | Forced air cooling |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message