Three-side Sealing Bag Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Three-side Sealing Bag Machine Solution

In today's increasingly growing food packaging industry, the demand for bags of plastic composite film and other materials has also increased. The three-side sealing bag machine is used for the production of various plastic-plastic, paper-plastic composite materials, which are widely used in plastic composite film, aluminum-plastic composite film, paper-plastic composite film and other three-side sealing. The bag is an ideal bag making device for all kinds of middle and sealed bags. At the same time, it is suitable for the manufacture of special-shaped bags such as stand-up bags, bump buckle bags and zipper bags.

Features and Benefits

Introduction

This system adopts VEICHI motion controller + servo bag making machine system with 4 1.3KW pull material servo, one 0.75KW rear discharge inverter, one 4KW main frequency inverter, and VEICHI high performance V5 motion controller (Hereinafter referred to as V5) as the control mechanism, the HMI is used for human-computer interaction, and the temperature control module controls the thermocouple heating through the solid state relay to reach the temperature of the customer's heat sealing. Normal operating speed can reach 120-150 bags / min (200mm bag length).

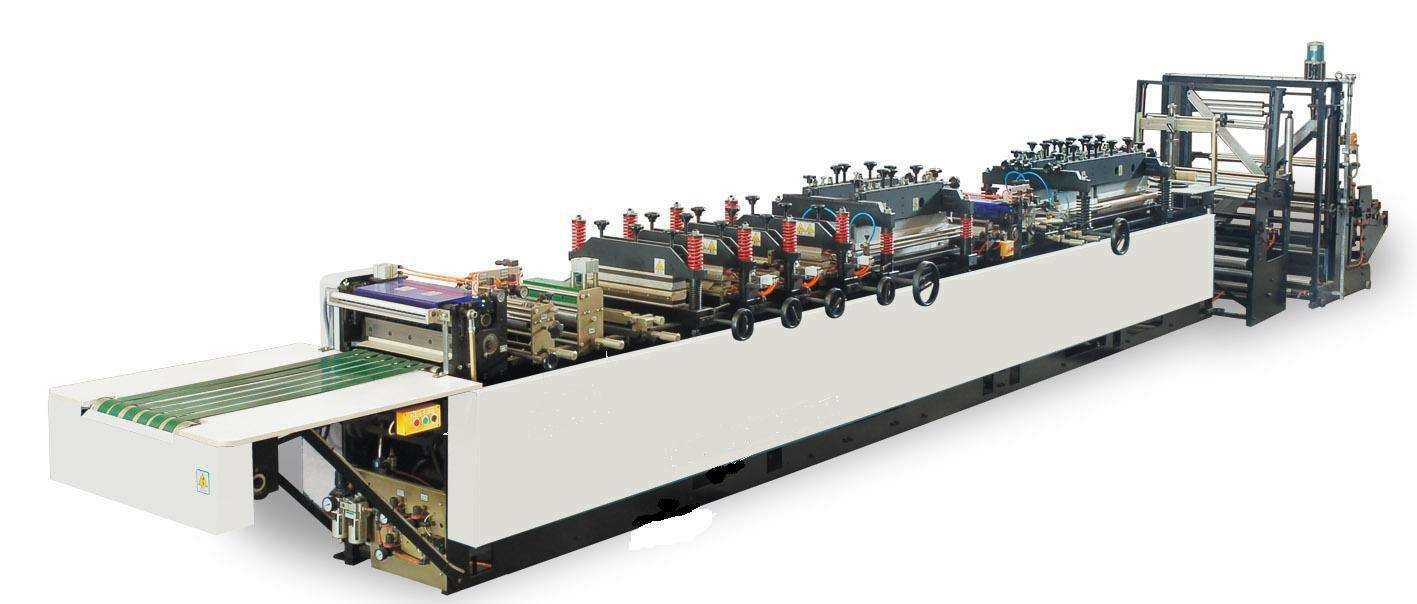

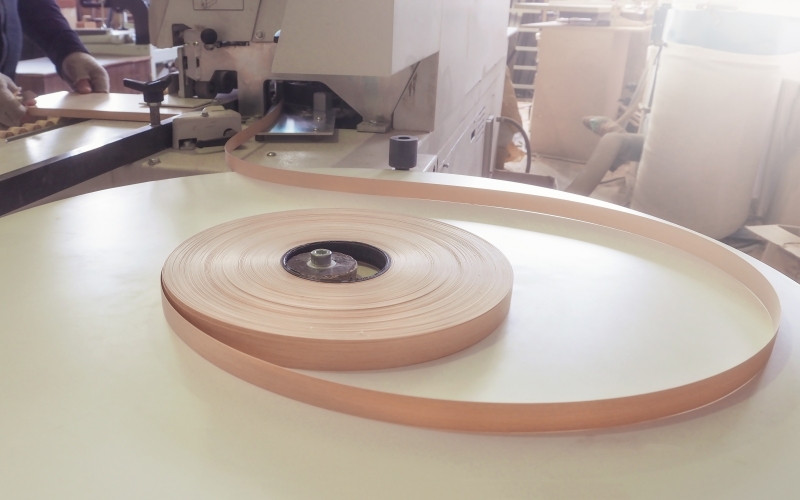

Figure 1: Three-side sealing bag machine

Equipment structure

1. The structure of the three-side sealing bag machine is mainly composed of the following parts:

1) Rear discharge mechanism: the inverter is controlled by the magnetic powder clutch to control the discharge tension;

2) heat sealing mechanism: driven by the frequency conversion device, to do the up and down reciprocating motion, the thermocouple heats the sealing knife to achieve the effect of sealing the bag, consisting of horizontal and vertical seals, transverse sealing on both sides of the bag for heat sealing, vertical sealing Heat sealing the bottom edge of the bag, the so-called three-side seal;

3) Feeding mechanism: The feeding roller is driven by the servo to achieve the purpose of feeding. It is necessary to ensure that the heat sealing mechanism sends the set length of plastic bag to the overheating sealing mechanism before leaving the cutting roller and reaching the cutting roller again. There are two kinds of servo working modes close to the cutter. One is the fixed length mode: the pulse of the set length stops when the pulse is finished, and the other is the calibration mode: the low pulse search for the set pulse number, the color code The photoelectric signal stops. The other three servos are synchronized with each other;

4)Cutting mechanism: cutting the bag with heat sealing;

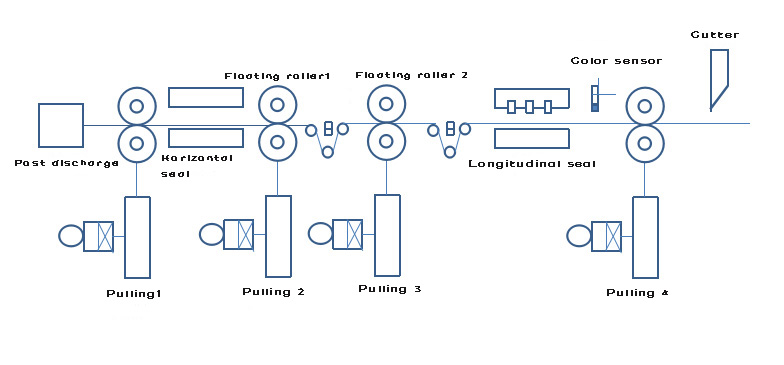

2. The structure of the three-side sealing bag making machine is shown in the figure below (Figure 2).

Figure 2: Three-side sealing bag machine structure

System solution implementation

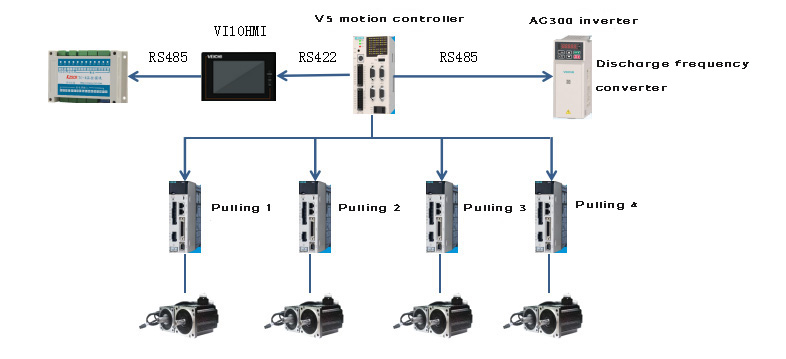

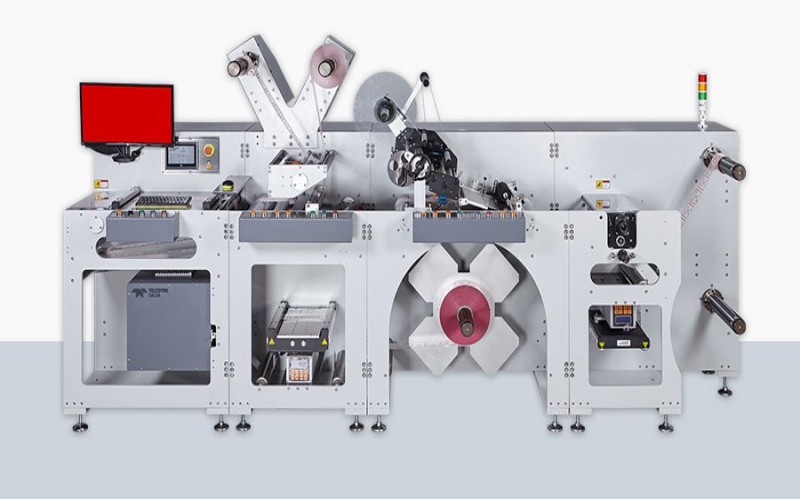

1. The VEICHI product and hardware components applied to the system are shown in the following figure (Figure 3).

Figure 3: System hardware components

2. Solution realization:

1) Using VEICHI high-performance V5-MC104 motion controller as the upper control, output pulse to position control of 4 pull servos, V5 has a unique 4-axis high-speed output design, the highest output frequency is 3MHz, the shaft port and SD700 The series servo has a separate dedicated cable, which requires no external wiring and is easy to install.

2) V5 communicates with the inverter RS485 for speed control, no analog output is required, saving analog output module; communicating with HMIRS422 to realize data interaction between HMI and controller;

3) The dual serial port HMI is used, and the other serial port communicates with the temperature control module RS485, which can control the temperature in real time, high efficiency and stability.

System advantage

1. The whole machine adopts our V5 motion controller. The dual CPU hardware architecture has faster processing speed, centralized control of human-machine interface, stable performance, easy operation and maintenance, and the operation interface can be switched between Chinese and English.

2. All parameters are displayed in real time by the man-machine interface, and the bag making speed, bag length, temperature, counting, etc. can be preset.

3. The temperature is adjusted by PID, adjustable from 0 to 300 °C, no contact automatic control, and the man-machine interface is set centrally.

4. Pneumatic multi-function automatic punching, automatic removal of edge material removal, with static elimination device.

Summary

The three-side sealing bag machine system of VEICHI has the advantages of high efficiency, good stability and strong anti-interference ability. It adopts a full set of our products to provide a total solution for the three-side sealing system, with simple operation, few adjustment parameters and easy maintenance. The system can meet customers' requirements for bag making of different materials and different specifications, which can effectively improve production efficiency, increase production capacity and ensure the overall performance of the system is stable, and meet the customers' comprehensive requirements for bag making systems.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message