Pillow Packaging Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Pillow Packaging Machine Solution

The movement curve of the horizontal sealing knife of the traditional pillow packaging machine is realized by the mechanical cam, which is complicated to install, has large running noise, troublesome adjustment and low efficiency.

Based on years of pillow bag development experience and market demand, VEICHI has developed a system with good user experience, efficiency and high precision. It has the functions of electronic air defense, electronic anti-cutting, torque anti-cutting, tracking mark, fixed length, etc., which can meet more market demands.

Features and Benefits

Solution Advantages

High-speed response and stability

The electronic cam function and high-speed arithmetic processing of VEICHI V5 series motion controllers ensure high response speed of the system.

Rich features

It has common functions such as electronic air defense, electronic anti-cut, and torque anti-cut. The anti-cutting moment can be set on the touch screen, it supports multi-section belt feeding, and supports variable-length packaging mode.

Simple to use

It is simple to debug the system, only need to set mechanical parameters, and support one-key writing of servo parameters.

Excellent performance

Running speed of fork type: single knife 20-300 bags/min. Running speed of belt type: 1-35 m/min. Packaging accuracy: color code accuracy ±0.5mm.

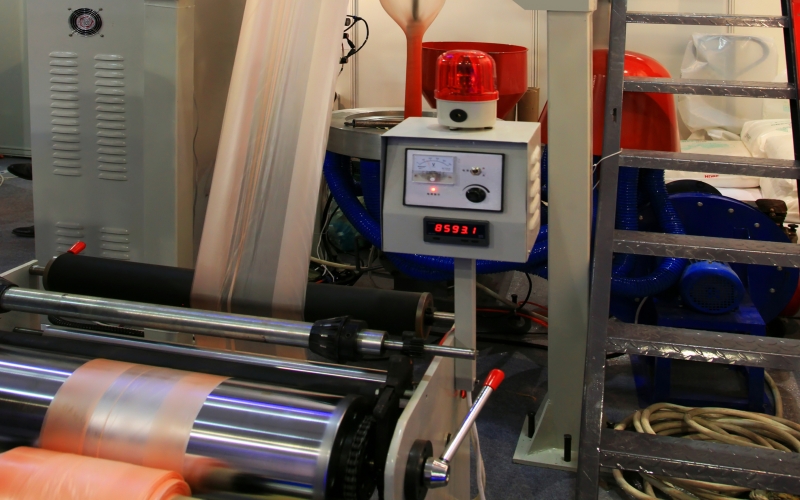

Industry Introduction

Pillow packaging machine is used for sealing packaging of articles, the machine is used for bag making, feeding, sealing, cutting, forming and so on. Pillow packaging machines are widely used in high-speed packaging in industries such as food, tableware, hygiene products, medicine, hardware parts, and labor protection supplies. Biscuits, candies, tableware are all packed by pillow packing machine.

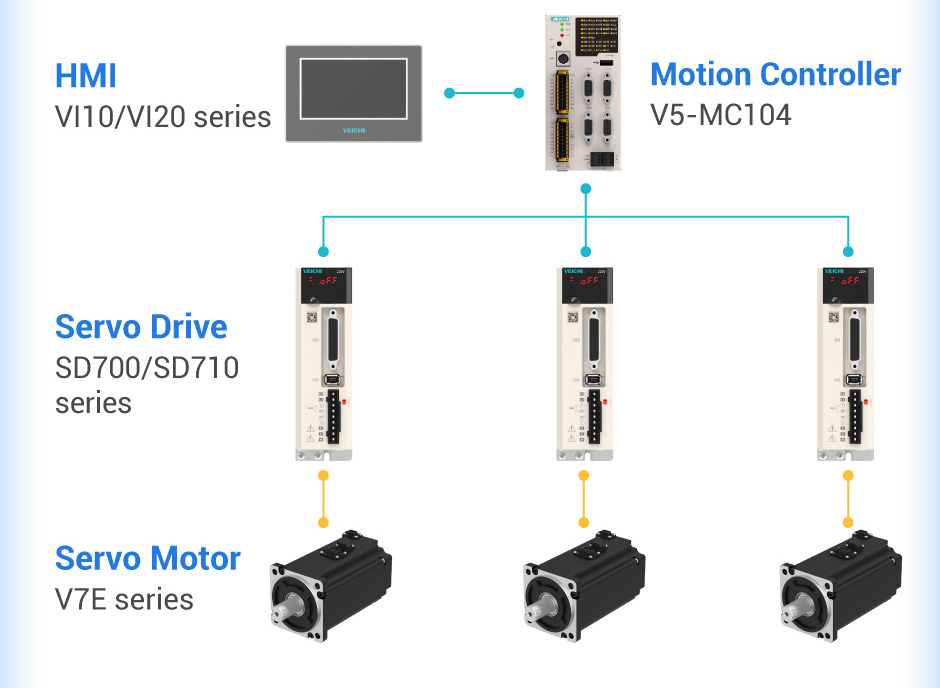

Solution Topology

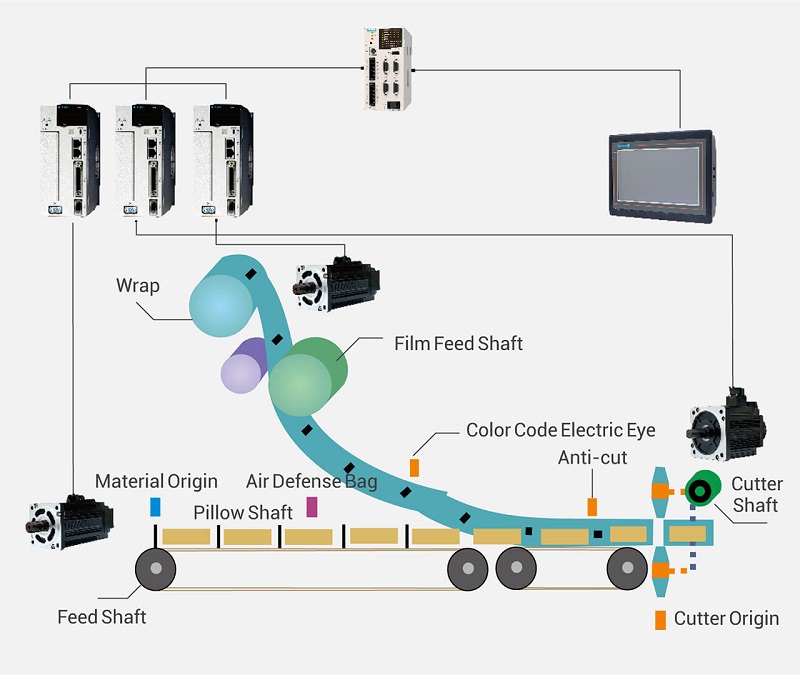

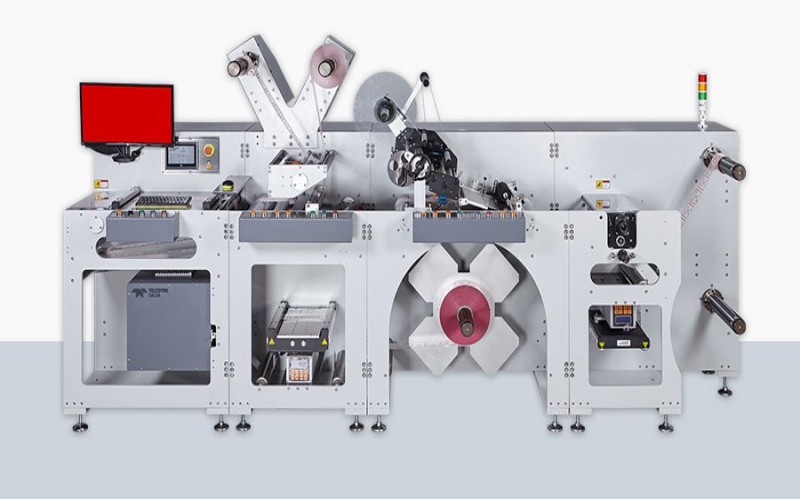

The pillow packaging machine drive system is composed of motion controller, Servo System, HMI, film shaft, cutter shaft, reel and etc.

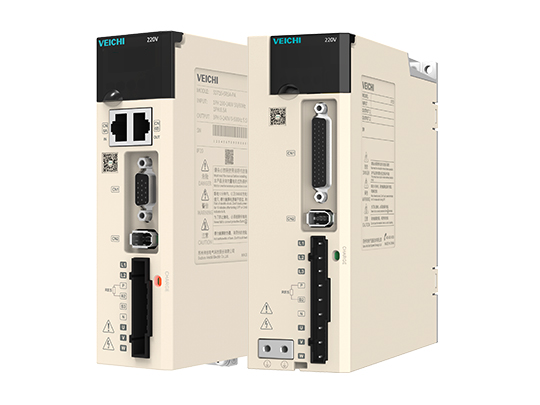

The solution adopts VEICHI V5-MC104 motion controller and internal electronic cam to achieve synchronous and precise control of each axis. Secondly, the hardware latch function cooperates with the mature color mark correction algorithm to ensure the high-precision operation of the color mark, feeding, and cutting knife. The specially developed software and hardware filtering function effectively filters out the on-site interference signal and realizes long-term stable operation under different working conditions.

System topology

The core components of the solution include motion controllers, touch screens, servo drives, and servo motors, all of which are independently developed by VEICHI. Compatibility and reliability are excellent, making operation and maintenance more convenient, and can effectively reduce customer after-sales investment.

System Principle

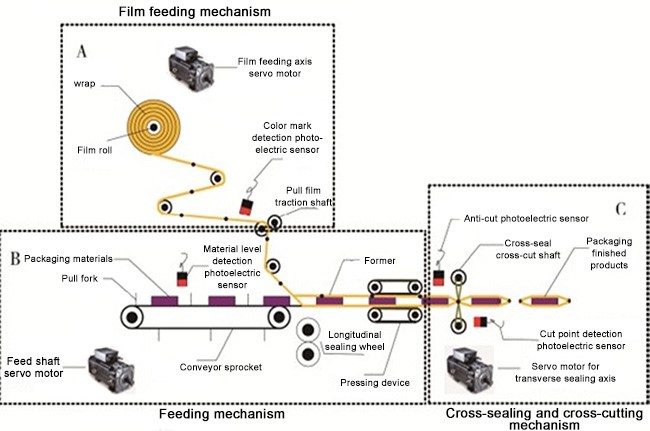

The packaging process of the pillow packaging machine is achieved by the coordination of the feeding shaft, the film pulling shaft and the cutter shaft to achieve the packaging purpose.

Reel feeding: The feeding shaft drives the fork to push the material forward, and the position of the sprocket of the feeding shaft is calibrated every circle to ensure the accurate feeding position.

Film shaft pull film: The film shaft drives the packaging film to feed the film more accurately according to the set bag length. In the color mark mode, the color mark signal is detected to compensate and correct the film feeding position. The coordinated operation of feeding and film feeding ensures that the material is accurately fed into the packaging film.

Shaft cut off: The knife position is compensated and corrected for each rotation of the cutter shaft. The linear speed of the cutter in the material-cutting synchronization area is kept consistent with the film feeding speed, and the film is synchronously sealed and cut transversely, and the packaged product is output.

Process Principle

The packaging process of the pillow packaging machine is achieved by the coordinated actions of the feeding shaft, the film pulling shaft, and the cutter shaft to achieve the packaging purpose. The feed shaft drives the shift fork to push forward and feed the material, and the sprocket of the feed shaft is calibrated every turn to ensure the accuracy of the feeding position. The film axis drives the packaging film to accurately feed the film according to the set bag length, and the color code signal is detected in the color code mode to compensate and correct the film feed position. The coordinated operation of feeding and film feeding ensures that the materials are accurately fed into the packaging film. The cutter position compensation correction is carried out for each revolution of the cutter shaft, and the cutter linear speed is maintained in the material cutting synchronization zone.

Technical Index

Speed index: single-pole 250-300 packs/min packing speed of shift fork model runs smoothly.

The variable-length packaging mode of the belt model supports a maximum packaging speed of 35 m/min.

Accuracy index: color code accuracy ±0.5mm.

Doing Business

VEICHI Electric offers professional advice and application design from our pillow packaging machine industry experts to support OEMs, ODMs, system integrators and industrial users. We also provide customized solutions for hardware and software that enable seamless integration and a range of features that optimize the total system.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message