Vertical Packaging Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Vertical Packaging Machine Solution

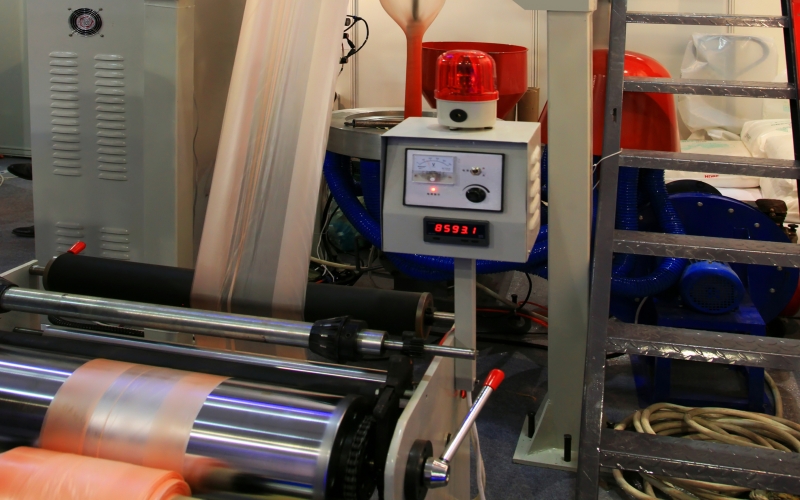

With the development of the times, we are now surrounded by a variety of bags, they are packed with a variety of food, daily necessities, such as bread, instant coffee, candy, sauces and so on. The vertical packaging machine OF VEICHI is used to package powders, granules and sauces.

Features and Benefits

The introduction of vertical packaging machine

Common vertical packaging machines are available in horizontal pull, back pull and continuous. This system is used for horizontal pull vertical packaging. Vertical packaging machine is generally divided into three parts: 1. the blanking part, 2. the film release part, 3. the packaging part. What we mean by cross and back pull is the difference in the packaging part. The blanking part has: 1. screw weighing, 2. rotating measuring cup, 3. combination weighing, and 4. liquid pump.

The system introduction

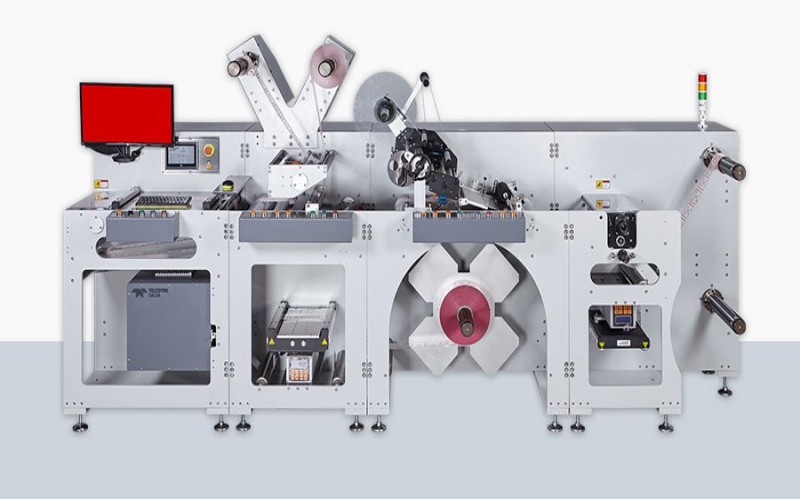

This system uses high-performance motion controller V5-MC104 of VEICHI as the control mechanism, VEICHI 750W high-performance servo SD700 series servo as the power of the film and screw power, VI10-070S touch screen as human-computer interaction. In addition, there are four temperature control modules to control the temperature of the solid state relay to control the horizontal seal and the middle seal. Under the color standard mode, the bag speed can be up to 80 packs/min under 130mm, and the precision is controlled within ±1mm under the condition of shifting. In the fixed-length production mode, the bag length below 130MM can reach 100 packs/min, and the precision is controlled within ±0.5mm under the condition of high speed and shifting.

The system program

1. The VEICHI products and hardware components applied by the system are as follows:

The VEICHI products and hardware components applied by the system

2. The program is implemented

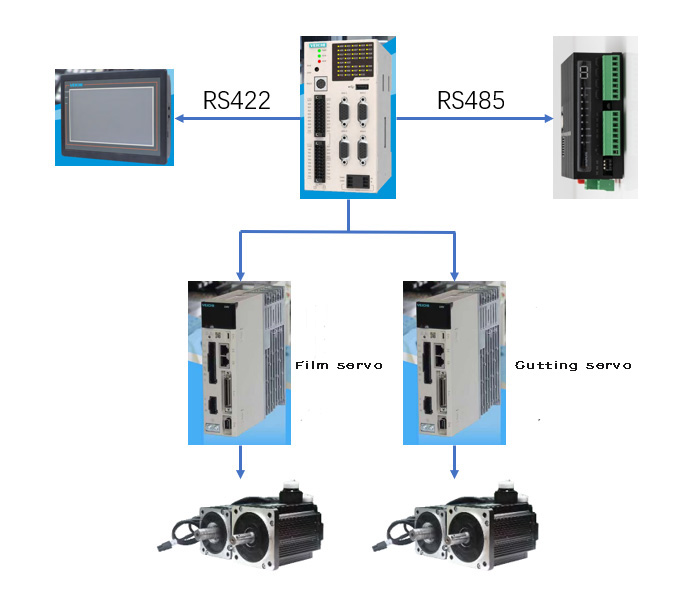

1) Using the VEICHI high-performance motion controller V5-MC104 as the upper control, precise control of the IO point and the film servo and feed servo.

2) The V5 controller and the temperature control module use RS485 communication to realize the control of the middle and horizontal seal heating and temperature control.

3) The V5 controller and the touch screen use RS422 for communication, and the user adjusts and views various parameters in real time on the touch screen.

System advantages

1. The whole machine adopts V5 motion controller of VEICHI, which has a unique 4-axis high-speed setting. The highest output pulse frequency is 3MHZ, which satisfies the ultra-high pulse frequency control. IO uses plug-in terminal blocks for easier wiring and cleaner wiring. It has a standard shaft connection with the servo, eliminating the need for additional wire bonding, saving time and effort.

2. HMI man-machine interface has centralized control of all operating parameters and stable performance. The interface can realize language switching, arrears lock, secret interface and other functions.

3. Control the temperature control module through RS485 communication to monitor and adjust the current temperature in real time.

4. The system intelligently calculates the given speed and actual speed and implements real-time speed adjustment.

5. The system is equipped with free filling function, customers can freely set any empty filling combination.

6. Real-time production, better control of production progress.

7. Open factory parameters for customers to adjust the coordination of actions between agencies in real time.

8. Implement recipe storage and reading in the controller, the operation is more intelligent and simple.

9. High-speed operation is stable, and the speed switching error is controlled at ±1 mm.

Summary

The horizontal vertical packaging machine of VEICHI has the advantages of high efficiency, low error and high stability. The system is easy to operate, the parameters are easy to understand, easy to monitor and adjust, and some factory parameters for fine-tuning are opened. The system can meet the process and accuracy requirements of most materials. It greatly improves the efficiency while ensuring the softness and precision of the action. Greatly meet the customer's performance requirements for vertical packaging.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message