Tension Control Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Tension Control Solution

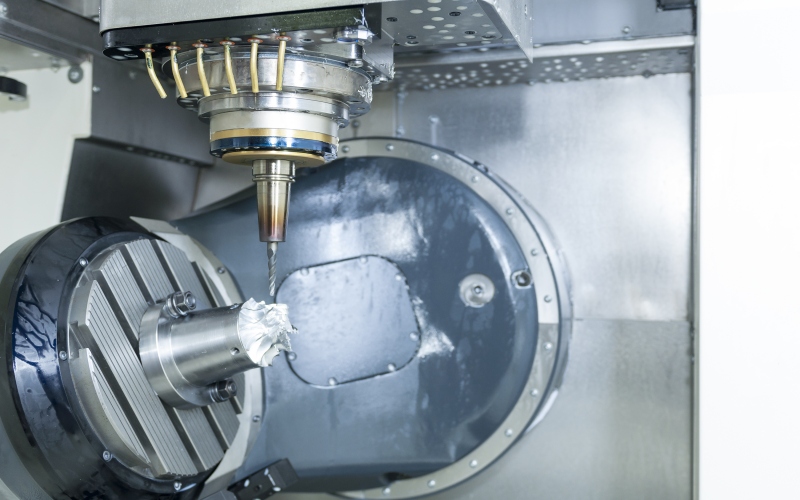

Printers and converters know that controlling tension in the web is essential to the quality of the product. Web tension upsets between, for example, an unwinding roll and the process may have several causes, including braking of the running roll, splicing action, acceleration of the new roll after splicing, and out-of-roundness or imbalance in the roll.

Features and Benefits

Industry introduction

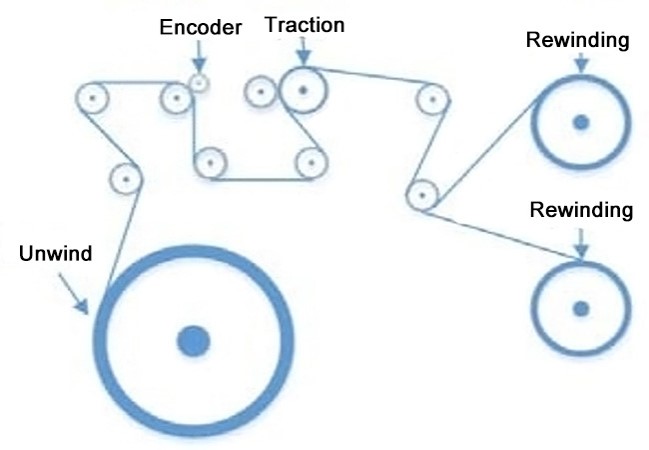

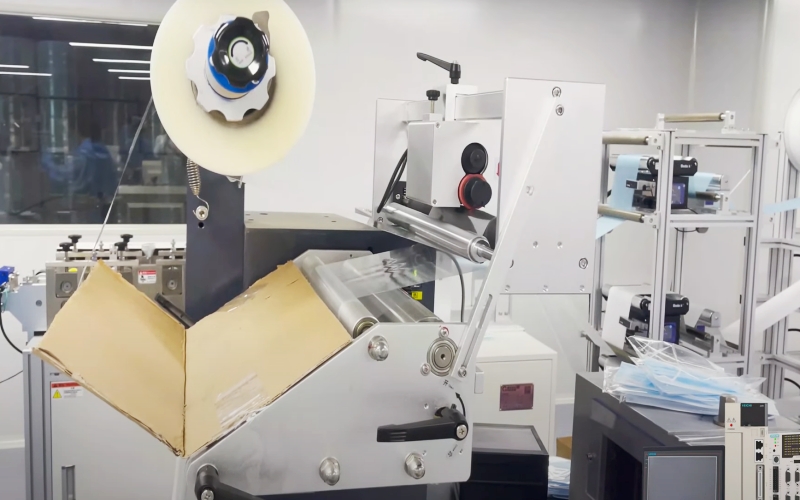

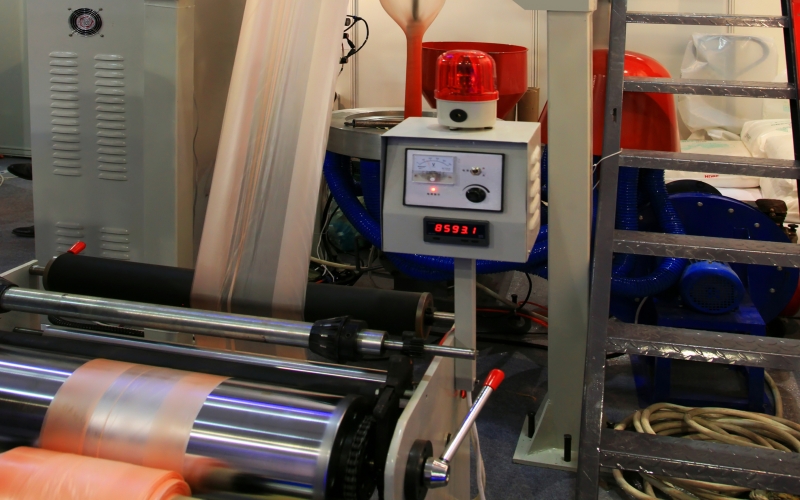

The tension control scheme is mainly used after the label is printed. After the label is printed, it needs to go through some processes before it can become a finished product. Tension control solutions for processes such as bronzing, die-cutting, coding, and inspection are mainly used in roll-to-roll equipment. And in actual application, in order to achieve different functions, the equipment will be used with different upper computers.

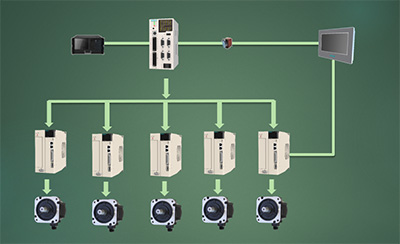

System topology

Practical application

1. Product inspection machine: If it is equipped with a visual inspection system to become a product inspection machine, its main function is to inspect the label printing quality, die-cutting quality, etc. If a defective label is found, it needs to be stopped for processing.

2. Inkjet printer: It becomes an inkjet printer with an inkjet control system. Its main function is to spray coded or variable information on the surface of the material.

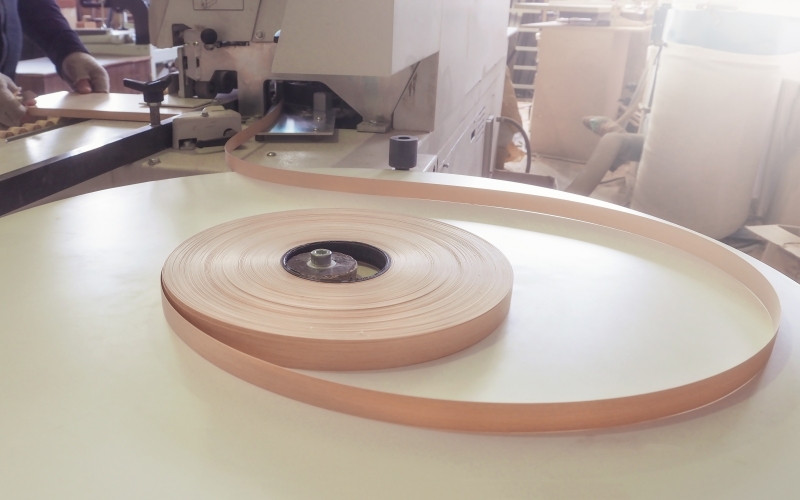

3. The slitting machine is equipped with a slitting knife on the equipment to become a slitting machine. The main function is to slit wide and multi-row materials into narrow and multi-row materials.

Process principle

1. Roll diameter calculation

After the equipment is running, the system calculates the real-time roll diameter of winding and unwinding by recording the feedback pulse of the encoder in real-time.

2. Tension calculation

Use the calculated roll diameter to adjust the torque output by the unwinding and unwinding servo in real-time to achieve the effect of adjusting the surface tension of the material.

3. General functions

The system also needs to have general functions such as meter counting, sheet counting, and output shutdown.

Program highlights

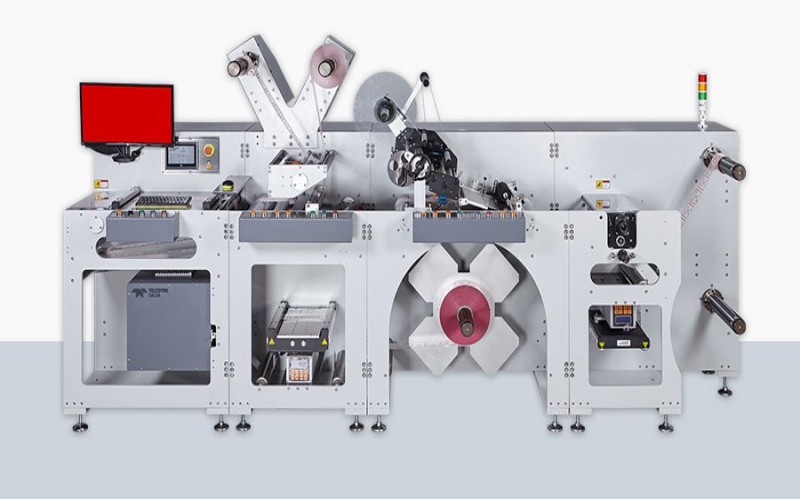

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster;

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. Support taper control, adjustable winding tightness;

4. The connection between V5 controller and servo adopts a high-speed differential signal, which has high stability and is not susceptible to interference. The maximum pulse speed of the differential pulse port is 3M, which can achieve extremely high control accuracy.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message