Automatic Dovetail Tenon Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Automatic Dovetail Tenon Machine Solution

The dovetail tenon is a right-angle connection node of flat wood. The trapezoidal tenon can make the corners of the workpiece high-strength joint and avoid detaching under stress. Because of its good mechanical properties, dovetail tenon is very common in wooden furniture.

The automatic dovetail tenon machine is easy to operate, relies on the control system, does not need to change the abrasive tools, cutting tools frequently, can be driven by linear guide rails, and can automatically complete the processing actions, it is popular in the market.

Features and Benefits

Industry introduction

The tenon-and-mortise structure is the main structural method of ancient Chinese buildings, furniture, and other wooden appliances.

It is mainly used for the right-angle connection of flat wood. The trapezoidal tenon can make the corners of the work piece join with high strength and avoid detachment under stress. Because of its good mechanical properties, dovetail tenon is very common in wooden furniture, and it is mostly used in drawers, wardrobes, etc.

Wooden furniture

As people's demand for solid wood furniture increases, the traditional dovetail tenon manufacturing process has been difficult to meet the huge market demand. In recent years, semi-automatic dovetail equipment and even fully automatic dovetail equipment have appeared on the market, greatly improving the production efficiency of solid wood furniture. The dovetail equipment system solution independently developed by VEICHI has been recognized by a large number of customers in the solid wood machinery industry for its advantages of high efficiency, high precision, and high stability.

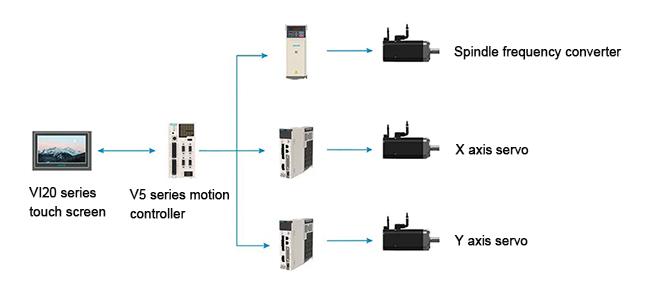

System topology

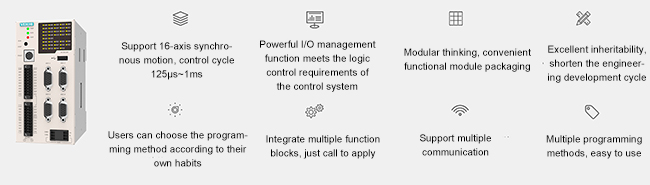

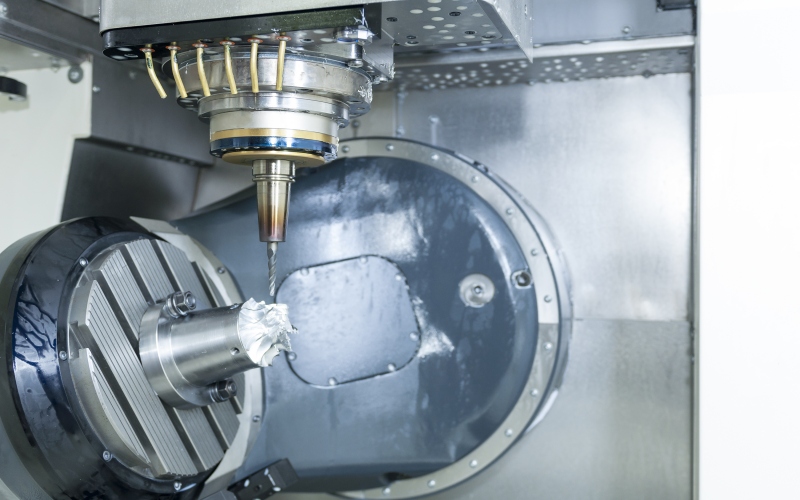

Fully automatic dovetail equipment control system adopts VEICHI V5 motion controller + VI20 series touch screen + SD700 series high-performance servo + AC310 series inverter. The controller realizes the motion trajectory planning in the dovetail tenon processing process through the high-precision interpolation algorithm, which ensures the accuracy and efficiency of the processing.

Fully automatic dovetail equipment control system

Live application

Fast processing speed and easy operation

The system uses VEICHI V5-MC104 motion controller, and the bottom processing speed of the dual CPU hardware architecture is faster. The man-machine interface is centrally controlled, stable in performance, easy to operate and maintain, and the operation interface can be switched between Chinese and English.

VEICHI V5-MC104 motion controllern

High efficiency and strong stability

The system adopts advanced application functions such as linear interpolation, circular interpolation, probe, etc., with higher processing efficiency and stronger stability.

High efficiency and strong stability

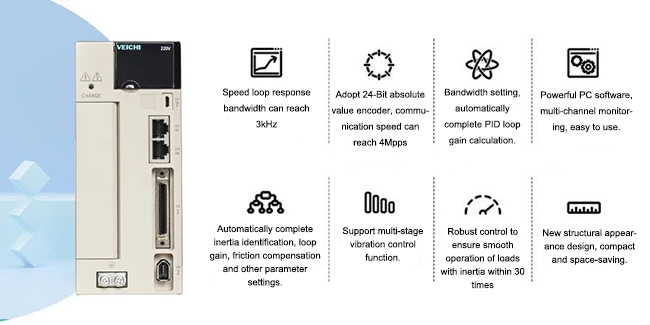

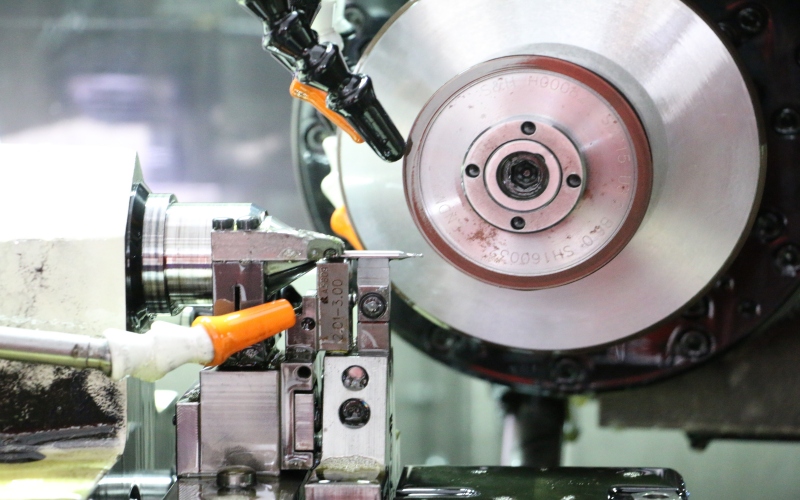

Servo response is fast and running smoothly

The system adopts SD700 series high-performance Servo System, which is easy to debug, the servo responds quickly and runs smoothly.

VEICHI SD700 Servo System

Simple debugging and flexible parameters

The system debugging is simple, there are few parameters needed for debugging, and the parameter setting is flexible.

VEICHI dovetail tenon joint equipment system solution has the advantages of high efficiency, good stability, strong anti-interference ability, etc., which can meet customer's demand for sheet metal processing of different specifications. In the future, VEICHI will continue the "guided by market demand, driven by technological innovation." concept to provide customers with competitive products and system solutions. To promote the high-quality development of the electric drive and industrial control industries, we are constantly striving to make progress.

Program highlights

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. The system adopts functions such as interpolation and probes, with strong stability.

4. The connection between the V5 controller and the servo adopts high-speed differential signals, which have high stability and are not susceptible to interference. The maximum pulse speed of the differential pulse port is 3MHz, which can achieve extremely high control accuracy.

Process principle

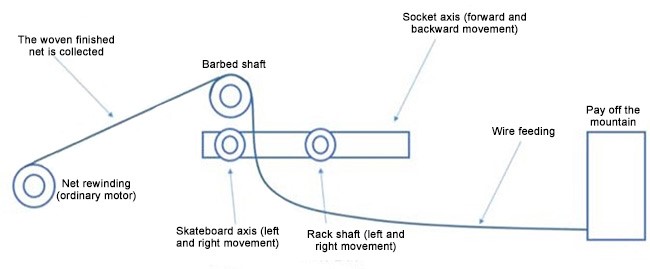

The dovetail tenon machine is mainly composed of the control system, fixture (cylinder), sawtooth plate (mold), processing platform, and other main parts.

1. Control system: VEICHI V5 controller + SD700 series servo + AC310 series inverter.

2. Cylinder (fixture): Four cylinders are used to clamp the wood.

3. Spacing tooth plate (also known as mold tool): used to hold the board.

4. Processing platform: XY axis driven by servo motor.

Technical index

The chamfering accuracy can reach 2 wires.

The processing width can reach 600mm.

Processing thickness is 8-32mm.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message