Automatic Liquid Filling Machine System Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Automatic Liquid Filling Machine System Solution

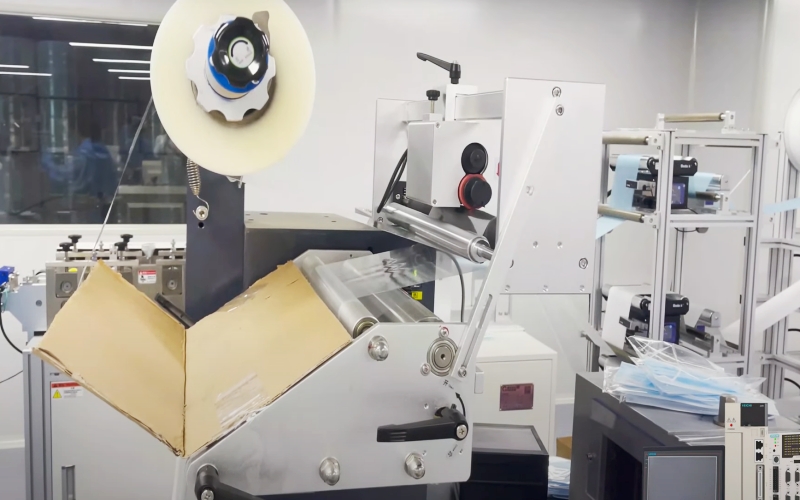

With the rapid development of my country's packaging industry and the continuous expansion of consumer demand for cosmetic preparations, dairy products, beverages, and other products. Liquid filling machines are favored by more and more manufacturers because of their easy operation and high production efficiency. However, in the actual use process, the waste of raw materials and cross-contamination caused by card machines, splashing, and canning accuracy errors also cause headaches for manufacturers.

Features and Benefits

With the rapid development of my country's packaging industry and the continuous expansion of consumer demand for cosmetic preparations, dairy products, beverages, and other products. Liquid filling machines are favored by more and more manufacturers because of their easy operation and high production efficiency.

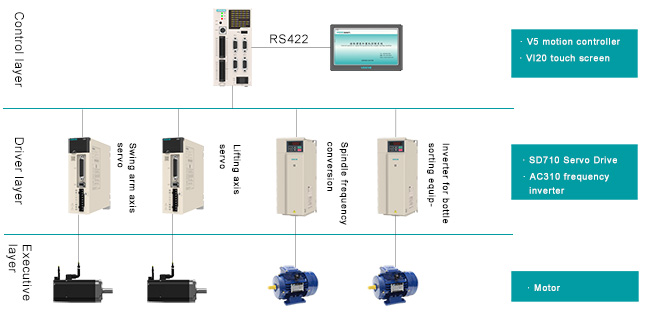

The automatic liquid filling machine system

System plan composition

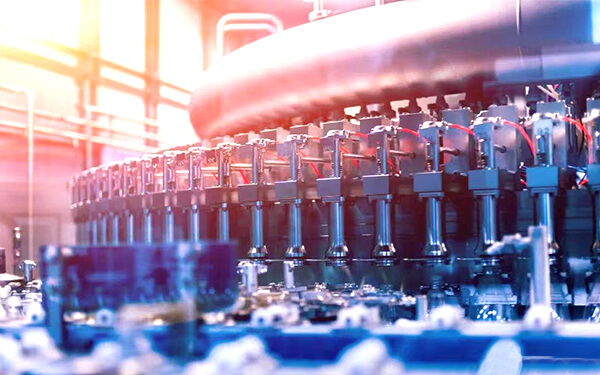

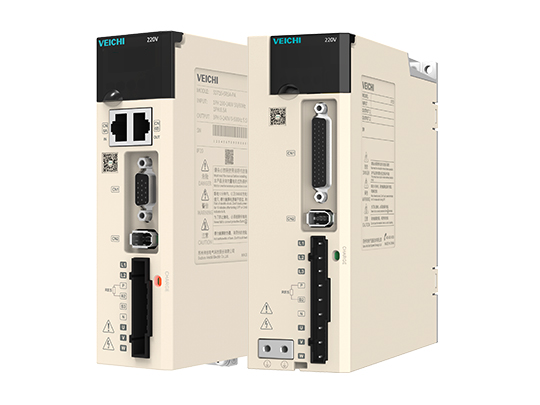

In response to the pain points of users, VEICHI combined its rich industry application experience to launch a fully automatic liquid filling machine system solution. The solution precisely controls the canned equipment through the self-developed V5 motion controller, SD710 servo drive, and AC310 high-performance inverter. A "smart brain" is installed on ordinary canned equipment. It not only greatly improves the accuracy and efficiency of canning but also helps customers realize the upgrade from traditional production to intelligent production.

System plan composition

System structure

System structure

Equipment for arranging bottles

AC310 high-performance inverter

Driven by AC310 high-performance inverter, it controls the equipment for sorting bottles and transports the empty bottles to be filled to the filling station area.

Swing arm servo

SD710 universal servo system

Driven by the SD710 universal servo system, the scanning arm of the liquid feeding needle tube moves synchronously with the bottle body in the canning section. The V5 motion controller "Flying Shear Function Block" is adopted to realize the function of synchronous liquid feeding and canning. The motion curve is a flying shear motion curve.

Lifting Servo

Driven by the SD710 universal servo system, it adopts the universal electronic cam function of the V5 motion controller. Control the liquid feeding lifting shaft to follow the main shaft linkage movement, so that it can complete the feeding liquid entering and exiting synchronously in the swing arm canning section.

System function realization

VI20 touch screen

The VI20 touch screen is used as the man-machine interface, which can perform alarm display, output display, and equipment reset. The control button can be used to control the start and stop of the corresponding function. The parameter interface is used to set process control parameters, position parameters, and other system parameters. The I/O monitoring interface is used to display the point status monitoring of various switching quantities. The historical alarm interface is used to record historical alarm information.

V5 controller

The V5 controller is used to precisely control the entire system and analyze the data of the touch screen. The function of flying shear and electronic cam is used for parameter setting information. Input the cam parameters into the corresponding register, and automatically calculate the servo running position and running speed. The touch screen displays the running position and running range of the current cam master and slave axes.

By comparing the interval and setting the cam ejector, the liquid feeding peristaltic pump can be controlled to start and stop within the cam interval. The canning cycle and interval are designed by reading the current encoder pulse number and detecting the signal of the bottle body interval, so as to realize the canning and inspection process without bottles and cans.

System advantages

System advantages

Independent research and development, stable and efficient

The core products of the entire system solution are high-performance equipment independently developed by VEICHI. Ensure that the entire electronic control system can achieve higher stability and compatibility. At the same time, it provides customers with more flexible solutions and more efficient after-sales service.

Replacing the tedious with simple, accurate, and reliable

The system feeds the swing arm shaft and feeds the lift shaft following the feedback pulse of the spindle encoder to make the electronic cam track motion. Compared with mechanical cams and positioning methods, its movement method is simpler, more precise, and more stable.

Missing detection function reduces losses

The no-bottle-no-can detection process can effectively realize the detection of missing bottles in the empty station interval. Control the opening and closing of the liquid delivery valve in the working area of the corresponding liquid pump. Greatly reduces the waste and loss of material canning.

Simple operation and comprehensive functions

The VI20 touch screen is used as the human-computer interaction interface. The interface layout is concise and the information functions are displayed accurately. And set up the control interlock function to prevent the on-site operator from misoperation and causing human-machine damage.

VEICHI has been deeply involved in the field of industrial control automation for many years. Always adhere to scientific and technological innovation as the core development strategy. Unswervingly provide safe, reliable, and efficient products and solutions for the industrial control industry.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message