Pharmaceutical Filling Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

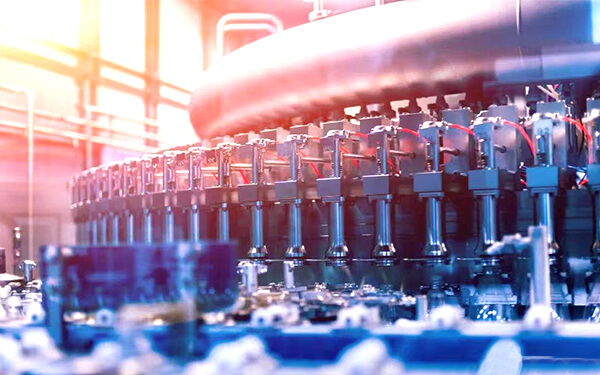

Pharmaceutical Filling Machine Solution

In recent years, with the rapid development of the light industry market and the increase in packaging demand, the market's requirements for filling machine equipment have continued to increase. The medicament filling machine is suitable for pharmaceutical, chemical, food, and other industries. It is a device for filling glass, plastic, metal, and other containers with vacuum negative pressure and self-priming liquid. The caliber of the machine used for the container to be filled should be small, and the expansion stress of the liquid surface in the caliber should be greater than the hydrostatic pressure. Such as oral liquid plastic bottle, eye drops bottle, cosmetic perfume bottle, battery liquid filling and so on.

Features and Benefits

Introduction

The medicament filling machine is suitable for pharmaceutical, chemical, food, and other industries. It is a device for filling glass, plastic, metal, and other containers with vacuum negative pressure and self-priming liquid. The caliber of the machine used for the container to be filled should be small, and the expansion stress of the liquid surface in the caliber should be greater than the hydrostatic pressure.

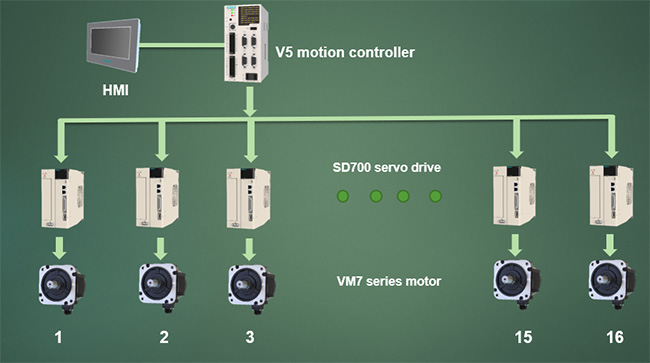

System topology

Program highlights

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

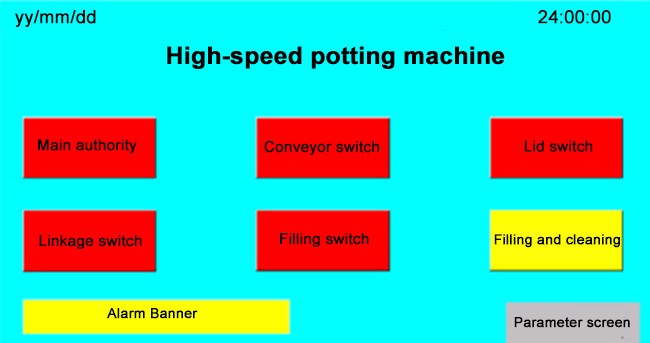

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. The connection between the V5 controller and the servo drive adopts high-speed differential signals, which have high stability and are not susceptible to interference. The maximum pulse speed of the differential pulse port is 3M, which can achieve extremely high control accuracy.

4. The data communication between the nodes of the CANopen communication network has strong real-time performance, strong anti-interference ability, high communication speed, easy implementation, and high-cost performance.

Process principle

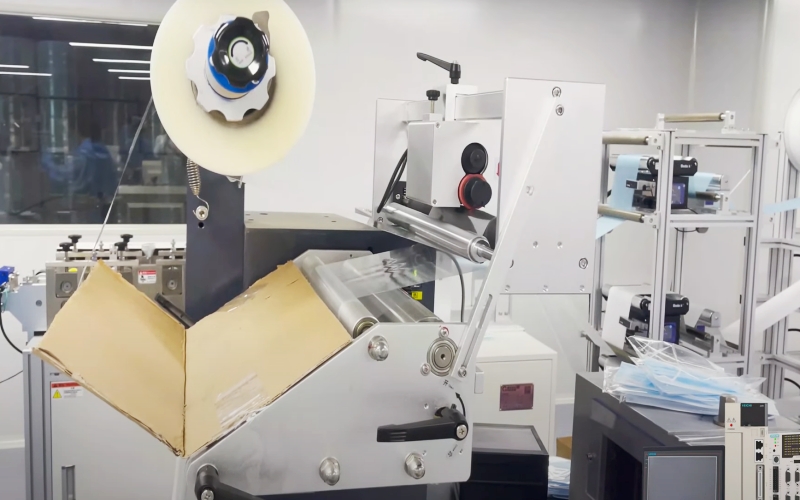

The pharmaceutical filling machine is mainly composed of a body, a conveying device, a filling part, a dial device, a cap supply system, a capping head, a bottle outlet tray, a tracking filling mechanism, and a transmission device.

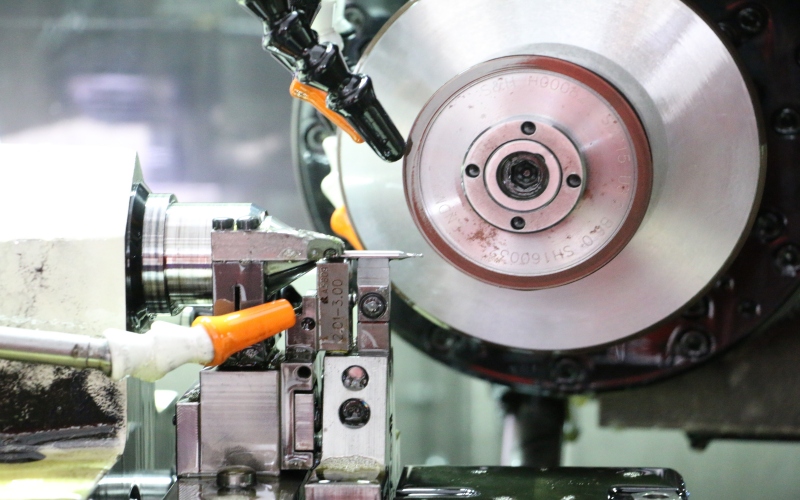

1. Transmission: The motor transmits the power to the worm gear shaft of the reducer through the belt pulley, and then the worm gear shaft passes the gears to transmit the power to the wheel shaft, the filling part, and the capping head. The filling part, capping head, and each dial move synchronously, and the power is transmitted to the bottle feeding dial device through the bevel gear.

2. Filling: Oral liquid bottles are sent from the large bottle-feeding wheel to the transition wheel, and then the transition wheel is sent to the timing belt, and the bottle is driven by the timing belt to move forward at a uniform speed. The filling needle is inserted into the mouth of the bottle under the control of the tracking mechanism and moves forward in synchronization with the bottle to realize tracking filling.

3. Lid supply: It consists of a lid conveying track, a lid arranging head, and a lid-wearing mechanism. The capping head adopts the principle of electromagnetic spiral oscillation to arrange the messy caps in a queue and send them to the cap feeding track. When passing through the capping mechanism, the bottle carries the cap through the capping plate to make the cap wear right.

4. Tracking filling mechanism: the filling needle is driven by the servo motor to make a reciprocating motion, and the filling needle can be accurately inserted into the bottle mouth by adjusting the relative position of the needle holder and the mounting frame.

Technical index

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message