Sand Making Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Sand Making Machine Solution

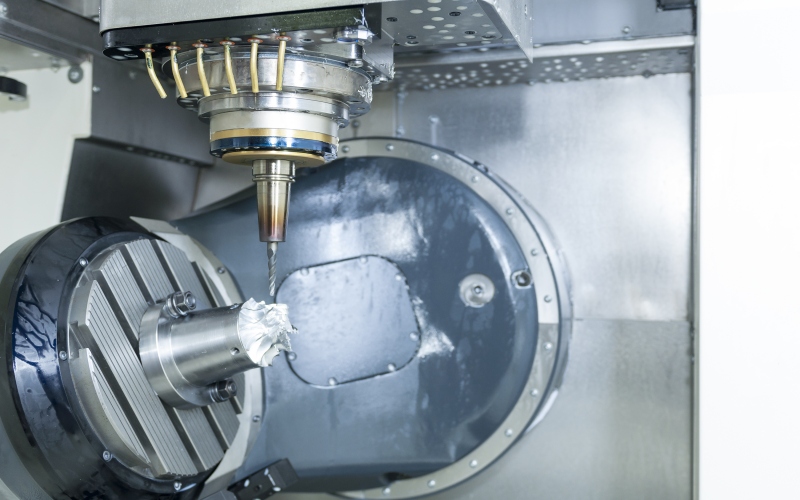

The sand making machine is a new type of sand making machine. After the structure is upgraded, the sand making efficiency is high, the sand control ratio is large, and the energy consumption is low. It is also used more and more in highway construction, hydropower, building materials and other industries, thus gaining industry recognition and rapid development. The supporting motor of the sand making equipment generally has a power of 45KW-400KW and an output of 50-500T / H. Compared with traditional sand control, the performance is more stable and efficient.

Features and Benefits

Composition of sand making machine

Sand making equipment usually consists of vibration feeder, crusher, sand making machine, vibrating screen, fine sand machine, belt transmission mechanism, electric drive control system, water circulation system and other links.

Working principle of sand control machine

Large pieces of stone are evenly fed into the jaw crusher by the vibrating feeder through the silo for coarse crushing. The coarsely crushed stone is sent to the impact crusher for further crushing through the vibrating screen. The finely crushed stones are sent to a vibrating screen by a belt conveyor for screening, and several kinds of stones are screened out. The stones that meet the requirements are sent to the fine sand machine by the conveyor belt. The stones that do not meet the particle size requirements are returned to the impact crusher by the belt conveyor to be crushed again to form a closed circuit multiple cycles. variable frequency speed regulation can produce particles of different sizes.

Defects of traditional sand making machines

Traditional electric drive control systems use step-down startup and have the following defects.

(1) The mechanical impact during startup is large, which accelerates the service life of mechanical equipment and belts. The instant of starting at the same time greatly affects the normal use of other electrical equipment.

(2) The system is not adjustable in speed, and cannot be flexibly adjusted with the feeding mechanism and the actual situation of production.

(3) If the crusher is blocked or the motor is out of phase, the motor cannot be protected in time, and the motor is easily damaged.

Advantages of VEICHI AC310 series on sand making machine

AC310 series inverters can drive ordinary asynchronous motors, synchronous motors, and synchronous reluctance motors, which realizes the drive control of electric drives that support various loads, so it can adapt to various different drive fields. Its vector control algorithms are based on the current internationally leading vector control theory algorithms, and further complete the model of the motor through software algorithms. A brand new magnetic flux observer is used to achieve lower motor parameter sensitivity, thereby achieving accurate current decoupling control. It guarantees high responsiveness and high precision speed control and torque control in the high-performance vector control of the above-mentioned different motors.

AC310 series inverters

Compared with traditional driving methods, it has the following advantages:

(1) Start smoothly and start torque is large, among them 0.5HZ can reach 150% of rated torque without PG vector control, and 200% of torque can be achieved with PG high-performance vector. It can guarantee low frequency and large torque.

(2) For the jaw crusher, due to the uneven feed, a sudden load change occurs when the inverter drives the motor to run. At this time, a large inrush current will be generated, and our inverter has a strong overcurrent suppression function to ensure that it will not stop during operation.

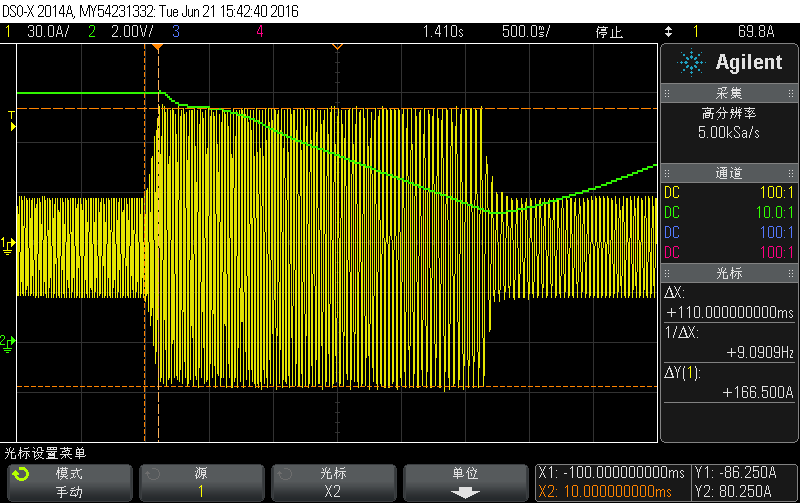

Overcurrent suppression function

(3) For the dual-motor coaxial-driven crusher, our software has a built-in power balance function, which can evenly distribute the load to each motor. Its start and stop are smooth and its performance is superior.

(4) The inverter has its own faults such as inverter overload, overcurrent, undervoltage, phase loss, and motor overload, which can ensure the reliable and stable operation of the sand production line.

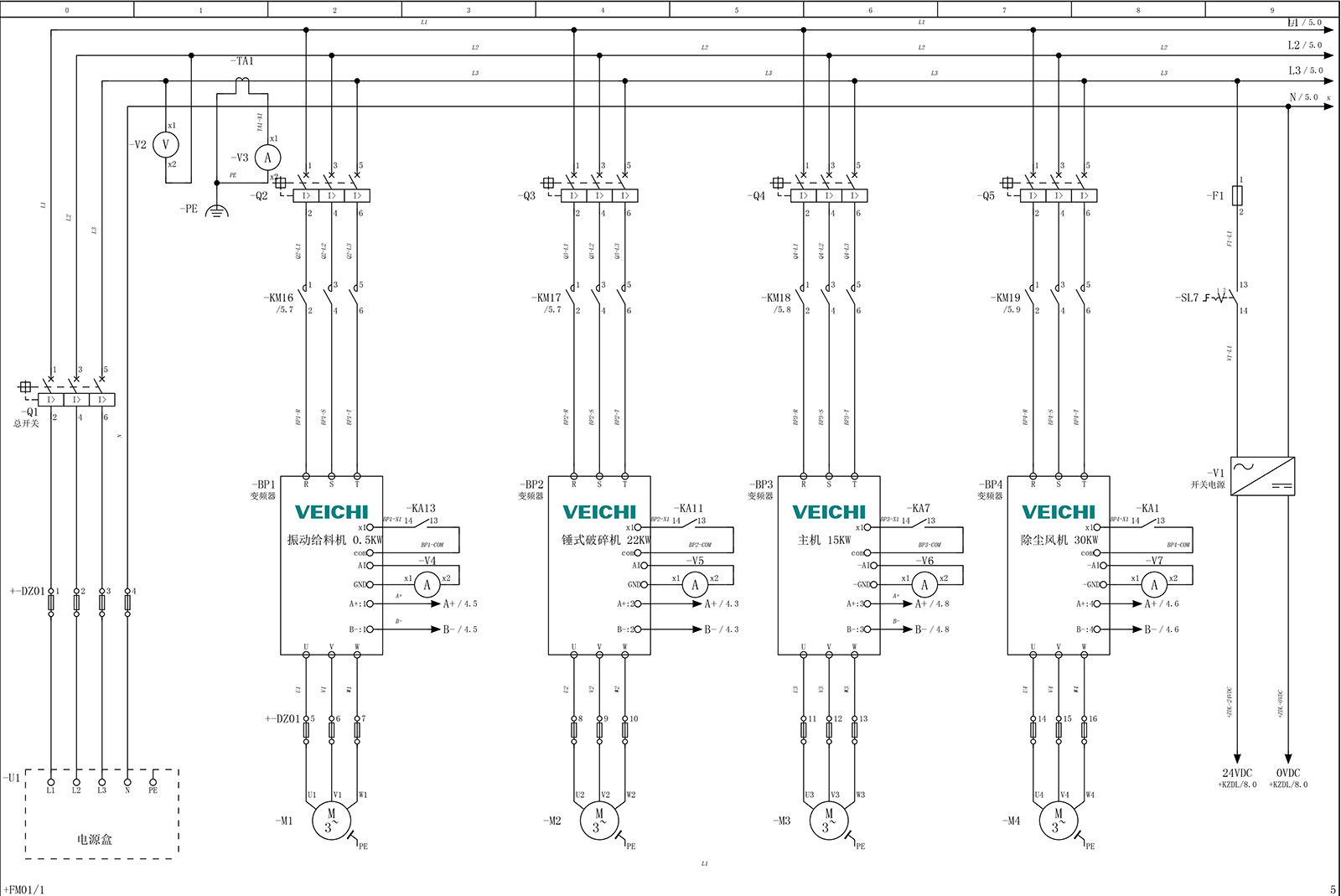

frequency inverter main control circuit diagram

Frequency inverter main control circuit diagram

Related parameter settings

1) Motor control mode F01.00 setting 1 open loop vector control;

2) Run command channel F01.01 setting 1 terminal control;

3) Frequency reference channel F01.02 setting 2 analog reference;

4) Motor parameter group F2 Set relevant motor nameplate parameters for self-tuning;

5) Acceleration / deceleration time is adjusted according to the actual situation;

Summary

AC310 series inverter of VEICHI drive control scheme has obvious application advantages in sand making machines, and can reliably and stably guarantee the operation of sand production lines. In accordance with the values of being customer-centric and development-oriented for the people, VEICHI keeps innovating and progressing, keeping pace with the times, and continuously providing customers with the best electrical drive solutions.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message