AC310 Frequency AC Drive VFD used on Dye Jigger in Bangladesh

Introduction

- Introduction

- Related Products

- Related Solutions

- Other Related Cases

- Additional Information

- Contact us

Overview

At present, cloth dyeing is an important process in the textile processing market.The dye jigger mainly deals with the process of bleaching, coloring, pressing and grinding to the finished fabric. There must be automatic counting (cloth loading number), automatic U-turn (bleach or dye repeatedly) and free stop (stable emergency stop without loose or drooping to cloth) functions in jigger control. During the whole process,the tensile tension and line speed of cloth should be kept an constant value. Therefore, it is required to have a higher automatic control level of the whole mechanical transmission system.

Process Requirements

Working as a center shaft curling control system, dyejigger uses two three-phase asynchronous motors, driving the roller with reducer to dye cloths.The finished fabric is firstly rolled to one of the rollers through roll-up motor, and a proximity switch is installed on the transmission shaft of the roller ( the proximity switch generates a pulse per circle). And at this time, the specialized tension controller is used to count the number of the next whole fabric. After rolling-up, one end of cloth is passed manually through the dye pool and linked shaft to be rolled to another cylinder and wrapped tightly. When the dye jigger is started, the fabric can be dyed.The two rollers move in the same direction, and it must maintain a constant tension on the fabric.Besides, the time fabric passing dye liquor should also be same, that is to maintain a constant line speed. There is no line speed and tension feedback in the drive control system, therefore, the output frequency of unwindinginverter and the output torque of winding inverterneed to be adjusted to meet the unique requirements of control system.

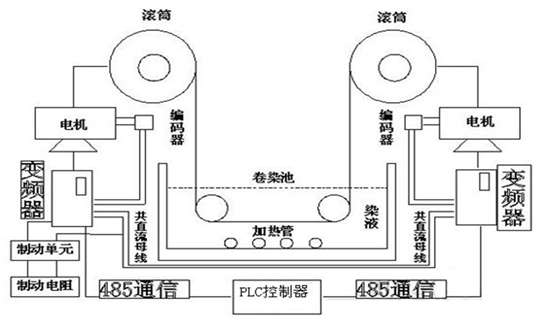

Control diagrammatic sketch

Solution of VEICHI Products

The dye jigger adopts VEICHI AC310 tension controller and VI10 HMI, which mainly set the fabric tension, running line speed, cloth thickness and the number of dyeing times, calculate the output frequency of unwinding motor and the output torque of winding motor, and control the logic operation of automatic U-turn and stop. It uses RS485 communication between inverter and controller (Modbus RTU communication protocol).

It could be seen from the control diagram that: Two same inverters (18.5KW) work under VC with PG mode. When loading cloths, the tension controller records the circle numbers of cloth rolled over the roller, and then the thickness of the cloth is measured by the operator to input to the controller, which will accurately calculate the diameter of the roller according to the thickness and circles.When the thickness integral method is used, the real radius of gyration can be easily obtained with small error.The controller accurately calculates the torque (winding motor) and matching frequency (unwinding motor) through the real radius of rotation, user's tension setting and line speed,and transmit them to AC310 inverter as the basic control parameters of winding and winding motor through serial 485 communication.Thus, the constant line speed and constant tension control are guaranteed, in which constant tension control is realized by torque control of AC310 inverter.

Basing on the working principle ofdye jigger, we can draw a conclusion that the unwinding motor is always in the state of power generation.Usuallythe braking unit and braking resistor are used to consume the power from load side in the form of heat. But a great waste of electric energy will be resulted in the equipment that works long-term in power generation. It also takes up the space of the electric control box because of the large resistance box.

AC310 high performance VC inverter supports common DC bus, and theDC bus of two inverters are directly paralleled. When the dye jigger works normally, the power generated by unwinding brake is fed back to the winding motor through parallel bus, thus the electric energy is fully utilized, greatly improving the power efficiency.But during fast stop, two motors are both in power generation state, and one of the inverters is still in parallel with a braking resistor, which works short time with little energy consumption, mainly preventing overvoltage fault caused by system stop.

Conclusion

The dyeing machine system with VEICHI inverter could achieve steady and reliable operation, and gain high economic benefits for customers. And VEICHI overall solution is highly praised by customers through the actual production test. The specific advantages are as below:

(1) Friendly HMI interface: all the parameters can be conveniently read and modified on the touch screen;

(2) variable frequency motor--reducer transmission: steady transmission, clean environment, no oil leakage, and less maintenance than hydraulic and DC transmission modes;

(3) Constant speed and constant tension in real sense:Constant speed and constant tension are ideal conditions for dye jigger to realize dyeing process. In the past, due to technical limit, it can not really be realized. With just one unit of active transmission mode, the constant line speed and constant tension can not be realized.There used to be a transition product with double DC speed regulation and dual frequencyinverter transmission is the ideal replacement product of hydraulic and DC transmission, which represents the development direction of jigger;

(4) High accuracy of tension and speed control: 300-1000n (continuous adjustable, precision ±5%),10~150m/min (continuous adjustable, precision±1%);

(5) High degree of automation: Automatic cycle counting and route counting, automatically roll back, automatic warming andlower labor intensity.One can monitor more than one machine; automatic temperature control to achieve constant-speed temperature rise and subsection temperature control. Automatic feeding to effectively overcome the common package dyeing difference;

(6) Flexible adjustment of process recipe toeffectively reduce the risk of orders, and easy to change color

(7) Strong adaptability of varieties: Because of PLC optimization program control, varieties have strong adaptability and the operation will not be affected by cloth thickness, which breaks the traditional view that the dyeing machine is not availableto thin fabrics;

(8) Large roller diameter: maximum 1.5m, generally thousands of meters per cylinder, or even more to effectively overcome the cylinder difference. The cylinder chasing is available even with tens of thousands of metersorders.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message