AC310 Frequency AC Drive used on Veneer Peeling Lathe in Vietnam

Introduction

- Introduction

- Related Products

- Related Solutions

- Other Related Cases

- Additional Information

- Contact us

Overview

The veneer peeling lathe solution raised by Veichi Electric has advantages of uniform thickness, smooth surface, small last veneer error and high timber utilization rate.

Working Principle of Veneer Peeling Lathe

The working principle diagram of veneer peeling lathe is shown as below. The log makes rotational motion under the co-driving of two fixed rollers and one moving roller to produce peeling power. The drive roller center support and the knife are relatively fixed and move together, in this way, the knife cuts out veneer from log. While the veneer thickness is controlled by the gap between the moving roller and the knife edge as well as the knife's moving speed. The gap between the moving roller and knife edge is relatively fixed and adjusted by the lathe equipment on basis of the veneer thickness. The control system adjusts the knife's speed by controlling motor's rotating speed, so the knife speed will indirectly determine the veneer thickness. Referring to the below diagram, the driving roller's rotating speed is constant, which means the log's constant linear velocity. The log's palstance will change with its diameter, in other words, the time a log required to spin a circle will follow the former change. In conclusion, the knife's moving speed is a variable value and a non-linear relationship. It's very important to design a system that can accurately control the knife's moving speed and achieve uniform veneer thickness. The basic ideas of system design is:

(1) Establish accurate mathematical mode.

(2) Take over the original speed control system to achieve accurate speed control.

Advantages of VEICHI AC310 for Veneer Peeling Lathe

1. The system that integrates the full digital control system and frequency inverter improves the response and eliminates the need for a PLC with large volume. It can greatly save costs by making the frequency inverter as the spindle drive power source and also the system control core.

2. The adopt of advanced algorithms and compensation methods can result in accurate, uniform and complete veneer thickness.

3. Using rotary encoder as the ranging sensor can increase the measurement accuracy to 0.01mm.

4. Using rotary encoder to measure the actual rotating speed of mobile platform can avoid the veneer thickness error caused by unstable grid voltage.

5. RS485 communication given will lead to less error.

6. Multiple choices of various sensor combination modes can meet customers' requirements to the most extent.

7. The system can continue to work without self-test in power failure situation, which brings great convenience.

Electrical Solutions

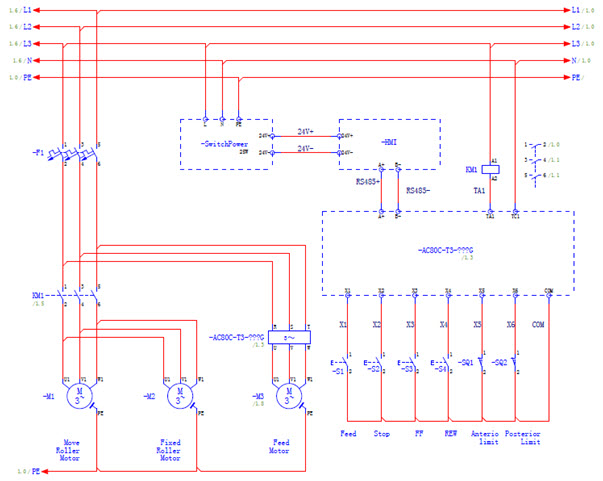

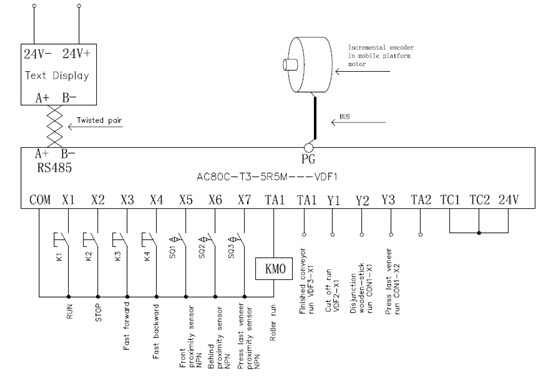

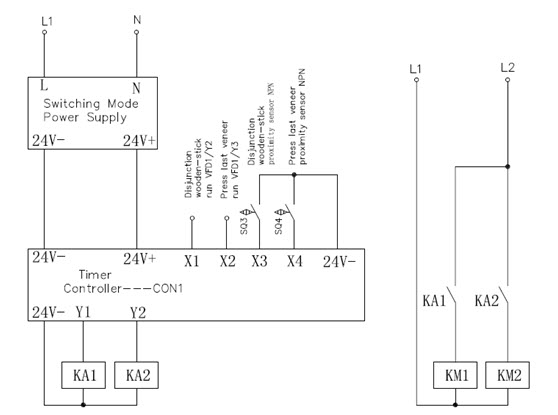

Wiring Diagram

Terminals of AC310

Power Supply Switch

Main Parameters and Debugging Procedures

F0.20=1

F2.10=0011

First----

F5.01=Number of motor poles

F5.02=Motor rated power

F5.03=Motor rated frequency

F5.04=Motor rated speed

F5.05=Motor rated voltage

F5.06=Motor rated current

F5.19=Extended PG pulse value

Second----F5.12=2

Then---Click the Keypad FWD button

When the in the FWD button is green Light is off, Auto study is finish.

HMI

wood ∮----wood Actual diameter

PeelFrqc----feed frequency

OCrrnt----output current

PeelThick----PeelThick

ActualDiameter----calibrate diameter

ResidualDiameter----remainder diameter

FastForwdFrqc----Fast forword frequency

FastRtrt----Fast backward frequency

AutoRtrt----Auto backward frequency

AutoStartPstn----Auto start position

RollerStartPstn---- Roller start position

MaxWood ∮----Max wood diameter

MinWood ∮----Min wood diameter

ForwardMode----Forward mode 0:roller and forward Simultaneous start

LeadScrewPitch----Lead screw pitch

Encoder----Encoder= (Actual Encoder*a) /b; a:PG frequency division b=transmission ratio

TransmissionRatio---transmission ratio-----actual

FixedRollers∮----Fixed rollers diameter

FixedRllrCntrDist----Fixed rollers center distance

FixedRollerSpeed----rollers speed

PGFrequcyDivision----PG frequency division ≈ transmission ratio(rounding)

Other parameters is not important, so you can ignore them.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message