SF81 Frequency Inverter used on Injection Molding Machine in Bangladesh

Introduction

- Introduction

- Related Products

- Related Solutions

- Other Related Cases

- Additional Information

- Contact us

Overview of Customer's Site

One of our Bangladesh customers uses the Haitian injection molding machine in his plastic factory, and the machine is powered by a 22KW motor-driven oil pump. Several months ago, our customer chose VEICHI SF81 asynchronous servo drive for energy-saving transformation.

Practical Situation Before Transformation

After the motor starts, it always runs at power frequency, so the actual oil pump fuel supply is greater than the actual requirements during the production process; the excessive hydraulic oil which is in the high pressure state flows back through the overflow valve, resulting in a lot of energy waste and valve wear; besides, there is further energy waste as reducing oil temperature needs additional cooling cycle.

Transformation Program

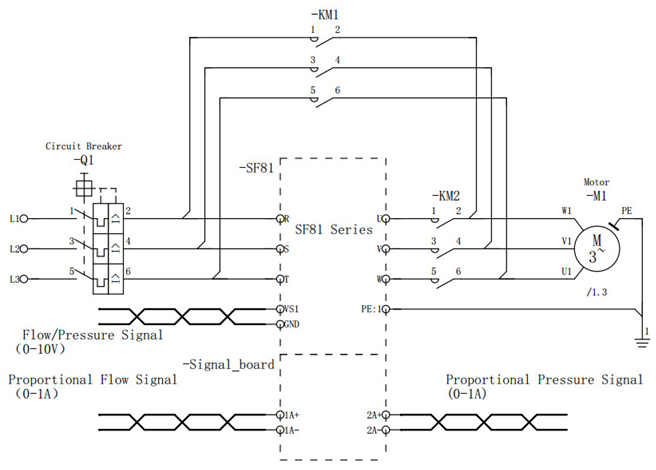

On the basis of full understanding of the customer situation, our technical engineer applied VEICHI SF81-T3-22ZK asynchronous servo driver to transform the injection molding machine system. Below is the wiring diagram.

Details of Energy-saving Transformation

Main Circuit Wiring

Cut off the star triangle main circuit power supply, and connect it to the U, V and W terminal of servo drive.

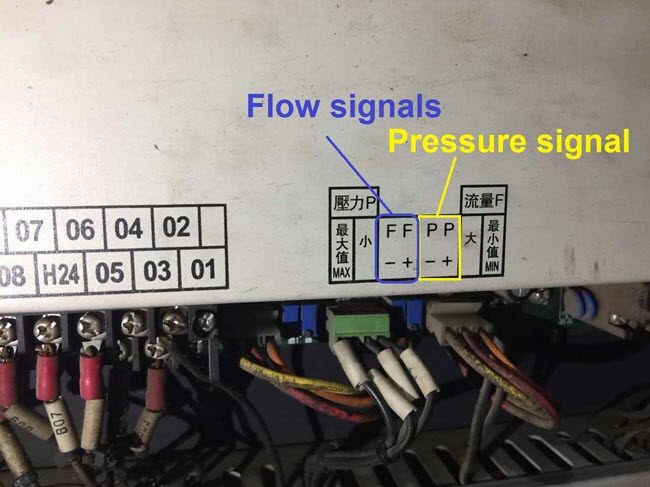

Signal board wiring

Wiring according to the proportion of injection molding machine computer or flow signal type 0-1A (DC) or 0-10 (DC).

1. Only need to connect one of the two signal board channels;

2. When the signal type is 0-1A, disconnect the original "signal positive" connection, series access 1A-, 1A +;

3. When the signal type is 0-10V, connect signal positive to VS, connect signal negative to GND, both connected in parallel to 1A-, 1A+.

Debugging

1. In manual mode, the NOZZLE ADV. Button or the NOZZLE RET. Button; when the C-16 changes from small to large, it indicates that the wiring is correct, and the motor running direction can be confirmed;

2. When the machine is in standby mode, monitor the C-16 parameter value, assuming the value is x;

3. Set F3.00 = X/10;

4. In the standby state of manual mode, set the maximum signal output, observe the C-16 parameter value at this time, assuming the value is Y;

5. Set the parameter F3.02 = Y/10;

6. Set the acceleration time F0.14 = F0.15 = 0.0-1.0 seconds;

7. In the automatic mode, set the driver operation running mode as variable-frequency, then debugging is completed.

Notes

1. The U, V, W wiring; confirm the motor running in the correct direction;

2. Find the flow or pressure signal terminals of the injection molding machine computer.

Highlights of VEICHI SF81

1. High energy-saving rate: the SF81 servo driver adjusts the output speed according to the injection molding machine computer signal, so that the actual pump oil supply meets the needs of the injection molding machine and various production processes. This can control the overflow in the minimum state, which saves 25% - 35% electricity.

2. Strong overload capacity: 150% rated current, 3 minutes; 200% rated current, 5 seconds.

3. High reliability: mains supply/ energy-saving operation of dual-circuit security switch design, ensuring the continuity and high efficiency of production.

4. Easy to operate: dual-channel input, can receive the pulse signal of 0 ~ 1A, 0 ~ 10V, below 50kHz; simple installation and superior protection.

5. High rate of return: all investment can be back through the electricity savings within 6-12 months.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message