- Home > Product > Electric Drive > Low Voltage Drives > AC330 Special Frequency AC Drive for Synchronous Reluctance Motor

AC330 Special Frequency AC Drive for Synchronous Reluctance Motor

- Brand-new high-performance vector algorithm platform, dedicated drive for synchronous reluctance motor.

- Accurate torque excitation decoupling, excellent dynamic response performance.

- Comprehensive thermal simulation design to ensure the rationality of hardware arrangement.

- Comprehensive expansion interface, rich selection of accessories, covering various applications.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

AC330 Special Driver for Synchronous Reluctance Motor Overview

The AC330 series ac drives are further optimized on the VEICHI AC310 product platform. Integrate the drive control concept of synchronous reluctance motor and develop a new vector control algorithm. Made a brand-new flux linkage observer. It has an excellent control effect in pure synchronous reluctance motor and permanent magnet auxiliary synchronous reluctance motor. At the same time, it is compatible with the control technology of asynchronous motors and permanent magnet synchronous motors. On the basis of ensuring the high reliability of the product, the software integration of the product is further improved, and the troubles of customers in product selection are better solved. With abundant expansion ports and comprehensive expansion accessories, it ensures the high reliability, high stability, and high adaptability of synchronous reluctance motor drive applications. VEICHI AC330 series ac drives provide customers with better drive services with a new and full attitude.

AC330 features

1. Brand-new high-performance vector algorithm platform, dedicated drive for synchronous reluctance motor.

2. Ultra-efficient energy-saving drive.

3. Accurate torque excitation decoupling, excellent dynamic response performance.

4. Comprehensive thermal simulation design to ensure the rationality of hardware arrangement.

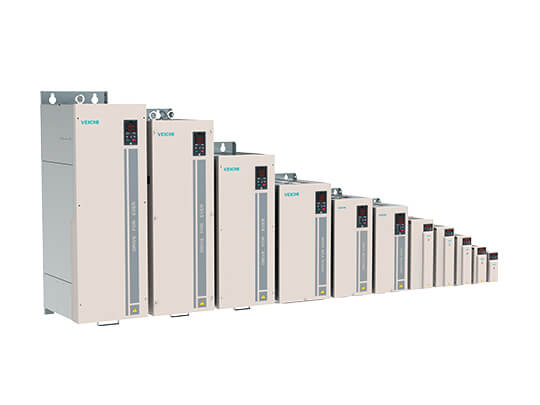

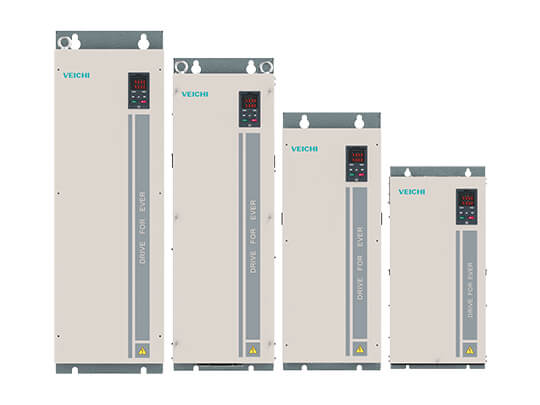

5. Full series of book design, saving installation space to the greatest extent.

6. Comprehensive expansion interface, rich selection of accessories, covering various applications.

7. Simpler and more convenient on-site debugging method, support on-site firmware upgrade.

8. The three-proof design of the whole machine and the three-proof paint of PCBA spraying ensure that the product is stable and reliable.

9. AC330 new EMC and grounding optimization, effectively solve electromagnetic interference.

10. Rich in expansion and reliable performance.

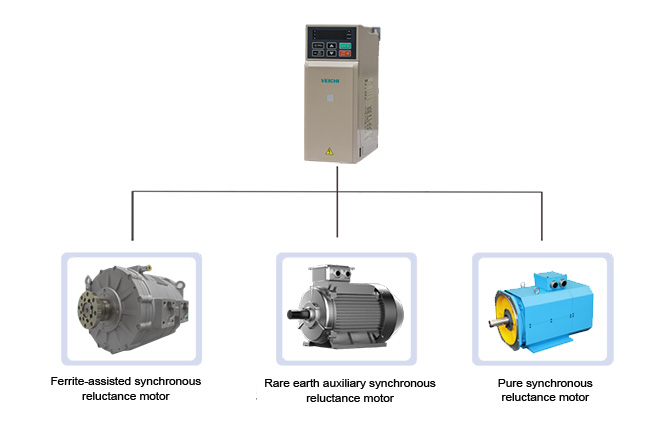

Dedicated for special ac drive, compatible with drive

AC330 series products continue the AC310 book-type carrier design, retaining the original product structure characteristics. It is also committed to solving the drive application requirements of high-efficiency synchronous reluctance motors and has developed a new inductance parameter saturation learning function. The integrated drive multi-form synchronous reluctance motor can be compatible with more than 90% of the drive needs of the synchronous reluctance motor industry.

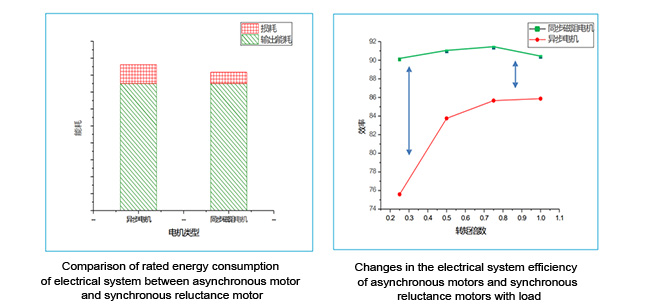

Better technology, energy saving and upgrade

AC330 series ac drives have developed a new and optimized MTPA algorithm to adapt to the high-efficiency drive of synchronous reluctance motors in the market. The dq axis stator current can be optimally distributed to minimize the stator current, thereby minimizing the stator copper consumption and achieving the best electrical operation efficiency.

In addition, matching the new generation of energy-saving control technology can realize the efficient operation of induction motors. According to the load situation, it automatically adjusts energy-saving, two-pronged approach, maximizes the motor efficiency, and reduces energy loss.

Market test statistics compare asynchronous motors. Underrated conditions, the system loss of driving synchronous reluctance motors is reduced by about 40%, and the efficiency at the rated point is increased by about 5%. The load rate is less than 50%, and the energy-saving effect is particularly obvious.

Excellent low frequency characteristics

AC330 drive synchronous reluctance motor speed regulation ratio is 50:1 (when the synchronous reluctance motor rated frequency is 50Hz, 1Hz can drive full load). It can effectively make up for the insufficiency of the low-frequency drive of the synchronous reluctance motor. Ensure that the low-frequency operation of the electrical system is more stable, and the drive load capacity is stronger.

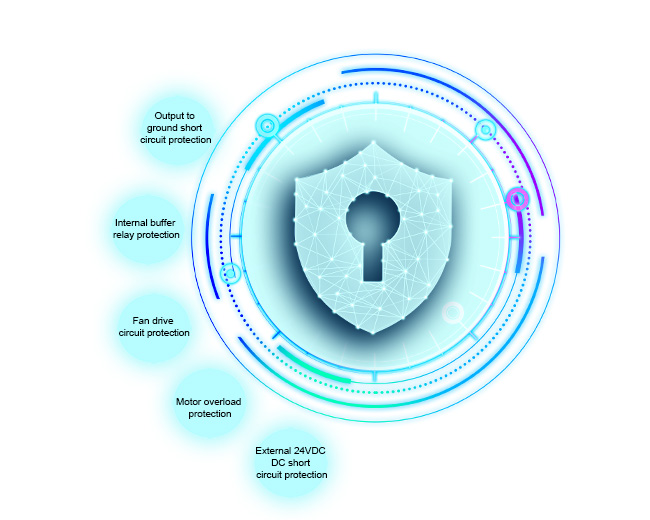

Comprehensive protection, stable and reliable

The AC330 series special drives are equipped with all-around protection of software and hardware for synchronous reluctance motors. It has the functions of output-to-ground short-circuit protection, internal buffer relay protection, fan drive circuit protection, external 24VDC short-circuit protection, and motor overload protection. Realize the full protection of the motor and peripheral equipment.

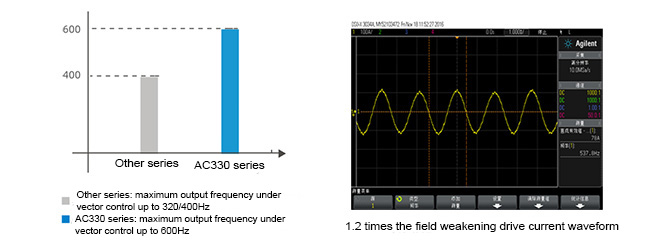

Excellent stability under weak magnetic field

The AC330 dedicated drive is equipped with a unique field weakening control algorithm above the base speed to maximize the use of voltage limits. In this way, the output torque is maximized, the constant power range is expanded, and the stability of operation under a weak magnetic field is guaranteed.

Expansion rich and comprehensive

AC330 series of special drivers for synchronous reluctance motors, with a variety of extended interfaces, to meet the needs of customization.

Two SPI high-speed channels are reserved on the product control board, which can support multiple expansion card selection applications at the same time.

Industrial Applications for AC330 Series Frequency AC Drive

It can be used for plastic machinery, air compressors, machine tool spindles, textile machinery, pharmaceutical machinery and other light industrial machinery needs. It can also be used for fans, pumps, petroleum, chemical, paper making machinery, and other heavy machinery and equipment.

Specifications

| Voltage and frequency | S2: single-phase 200V ~ 240V 50Hz/60Hz; T2: three-phase 200V ~ 240V 50Hz/60Hz T3: three-phase 380V ~ 480V 50Hz/60Hz; T6: three-phase 660V ~ 690V 50Hz/60Hz |

|---|---|

| Allowed fluctuation range | T/S2: -10% to 10%; T3: -15% to 10%; T6: -10% to 10% Voltage imbalance rate: <3%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements |

| Switching impulse current | Less than rated current |

| Output voltage | Output under rated conditions: three-phase, 0V ~ input voltage, error less than 5% |

|---|---|

| Output frequency range | 0Hz~600Hz |

| Output frequency accuracy | ±0.5% of maximum frequency value |

| Overload capacity | G type: 150% rated current 89s, 180% rated current 10s, 200% rated current 3s P type: 120% rated current 35s, 140% rated current 7s, 150% rated current 3s |

| Motor control mode | V/F control, open-loop vector control, closed-loop vector control, voltage and frequency separation control |

|---|---|

| Modulation method | Optimized space vector PWM modulation |

| Carrier frequency | 1.0~16.0kHz |

| Speed control range | No pg vector control: rated load 1:50 (synchronous reluctance motor) Without pg vector control: rated load 1:200 (asynchronous motor, permanent magnet synchronous motor) With pg vector control: rated load 1:1000 |

| Speed accuracy in steady | Without PG vector control: ±0.5% (three-phase asynchronous motor), ±0.1% (permanent magnet synchronous motor) With PG vector control: ±0.02% |

| Starting torque | No PG vector control: 100% rated torque at 2Hz (synchronous reluctance motors) Without PG vector control: 150% rated torque at 0.25Hz (asynchronous motors, permanent magnet synchronous motors) With PG vector control: 200% rated torque at 0Hz |

| Torque response | No PG vector control: <10ms; With PG vector control: <5ms |

| Frequency accuracy | Digital setting: maximum frequency × (±0.01%); analog setting: maximum frequency × (±0.2%) |

| Frequency resolution | Digital setting: 0.01Hz; analog setting: maximum frequency × 0.05% |

| DC braking capability | Starting frequency: 0.00Hz~50.00Hz; Braking time: 0.0s~60.0s; Braking current: 0.0%~150.0% rated current |

|---|---|

| Torque boost | Automatic torque boost 0.0% to 100.0%; Manual torque boost 0.0% to 30.0% |

| V/F curve | Four types: linear torque characteristic curve, self-setting V/F curve, descending torque characteristic curve (1.1 to 2.0 power), square V/F curve line |

| Acceleration and deceleration curves | Two ways: linear acceleration and deceleration, S-curve acceleration and deceleration Four sets of acceleration and deceleration time, time unit 0.01s, maximum 650.00s |

| Rated output voltage | Using the power supply voltage compensation function, it can be set within the range of 50% to 100% with the rated voltage of the motor as 100% (output cannot exceed input voltage). |

| Automatic voltage adjustment | When the grid voltage fluctuates, it can automatically keep the output voltage constant |

| Automatic energy-saving operation | V/F control mode automatically optimizes the output voltage according to the load to achieve energy-saving operation |

| Automatic current limiting | Automatic current limitation during operation to prevent frequent overcurrent fault tripping |

| Instant power-off processing | Uninterrupted operation through busbar voltage control during transient power failure |

| Standard function | PID control, speed tracking and power-down restart, jump frequency, upper and lower frequency limit control, program operation, multi-segment speed, RS485 communication, analog output, frequency pulse output, parameter access level setting, common parameter setting, monitoring parameter comparator output, counting and communication, analog output, frequency pulse output, parameter access level setting, common parameter setting, monitor parameter comparator output, counting and timing, frequency swing function timing, Frequency swing function. |

| Frequency setting channel | Keypad digital setting, keypad potentiometer, analog voltage/current terminals AI1 and AI2, communication feed and multi-channel terminal selection, primary and secondary channels Combination, switchable by various means |

| Feedback input channel | Voltage/current terminals AI1 and AI2, communication feed, pulse input PUL |

| Run command channel | Operator panel feed, external terminal feed, communication feed |

| Input command signal | Start, stop, forward and reverse rotation, jogging, multi-speed, free stop, reset, acceleration and deceleration time selection, frequency setting channel selection, external Fault alarm. |

| External output signal | 1 relay output, 1 open collector output, 1 AO output selectable as 0V to 10V or 0mA to 20mA or 4mA to 20mA output, or frequency pulse output. |

| Protective function | Overvoltage, undervoltage, current limit, overcurrent, overload, electronic thermal relay, overheat, overvoltage stall, data protection, flying speed protection, input and output phase loss protection. Input and output phase loss protection |

|---|

| LED display | Built-in keyboard: single line 5-digit digital tube display, 1 inverter status quantity can be monitored External keypad: single line, double line 5-digit digital tube display, Two lines can monitor 2 inverter status quantities |

|---|---|

| Copy of parameters | Upload and downlink inverter function code information for fast parameter replication |

| Condition monitoring | Output frequency, given frequency, output current, input voltage, output voltage, motor speed, PID feedback amount, PID feed amount, module temperature, given torque, output torque and all parameters of the monitoring parameter group. |

| Faults alarm | overvoltage, undervoltage, overcurrent, short circuit, phase loss, overload, overheat, overvoltage stall, current limit, data protection damaged, current fault ,operating conditions, historical fault records. |

| Installation location | Altitude lower than 1000m, with a reduction in use above 1000m and a reduction of 1% for every 100m of elevation. No condensation, icing, rain, snow, hail, etc., solar radiation below 700W/m², air pressure 70kPa~106kPa. |

|---|---|

| Temperature and humidity | the rated power is reduced to use when the temperature is above 40°C at -10°C~+50°C, maximum temperature is 60°C (no-load operation) 5%~95%RH (non-condensing) |

| Vibration | 5.9m/s² (0.6G) at 9Hz to 200Hz |

| Installation mode | Wall-mounted |

| Protection class | IP20 |

| Cooling method | Forced air cooling |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message