- Home > Product > Electric Drive > Low Voltage Drives > AC10 Series Variable Frequency Drive - AC Drive

AC10 Series Variable Frequency Drive - AC Drive

- Smart and compact, with a narrow book design.

- Temperature resistance, no derating in 50℃ environments.

- Support a variety of installation methods.

- Compatible with asynchronous/synchronous motors with high-performance vector control.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

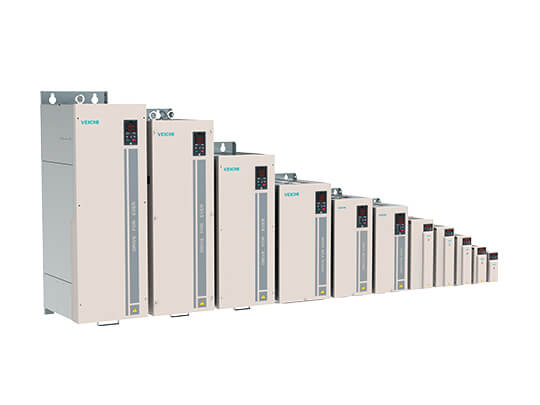

AC10 Series Frequency Drive Overview

AC10 series frequency drive is a product developed on the latest technology platform of VEICHI. AC10 products are based on the user's market demand for miniaturization, high reliability and high cost performance. As a narrow-body VFD, AC10 has convenient way of installation, small size, low temperature rise, high protection, strong software performance and many other advantages. AC10 development relies on advanced PLM R&D management system to ensure that the hardware, software, structure and test process are three-dimensional, systematic and can be developed during the development process. Traceability, constant scrutiny in every detail ensures strict rigor and scientific spirit (T3 VFDs only support vector control).

AC10 VFD Product Features

1. Smart and compact, with a narrow book design.

2. Various installation methods, rail, side, vertical installation.

3. Temperature resistance, no derating at an ambient temperature of 50℃.

4. Hidden line design makes wiring more convenient.

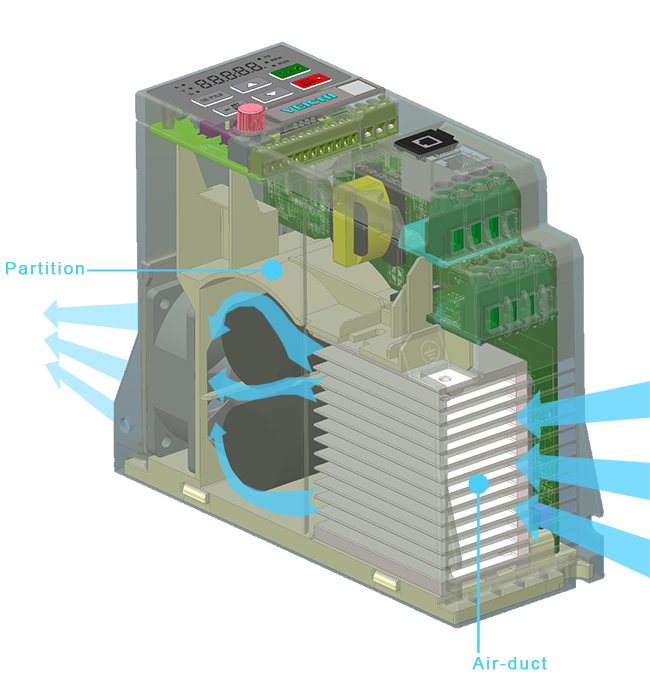

5. High protection, isolated air duct, taking into account heat dissipation and dust prevention of devices.

6. Multiple protections, over-current, and over-voltage protection all the time, wave-by-wave current-limiting protection.

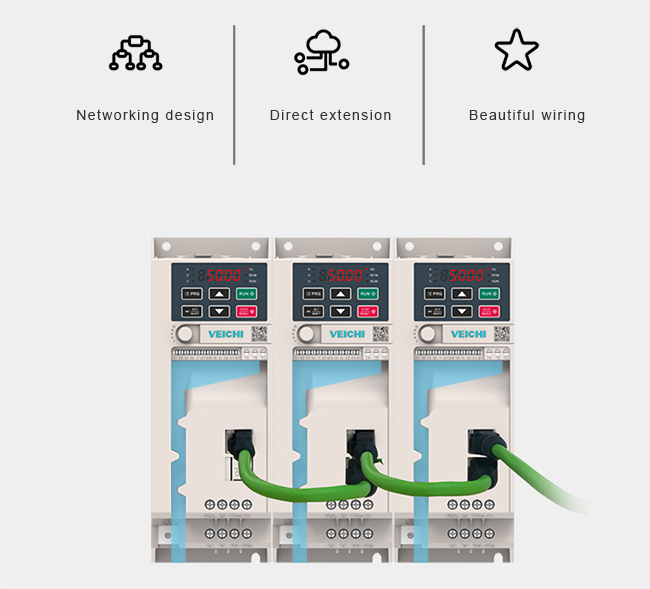

7. Network design, convenient network expansion, direct plug-in direct expansion.

8. Power performance, undiminished functions, small but versatile.

Save twice the installation space, book narrow body design, various installation methods

1. Install side by side, no need to reserve clearance.

2. Side installation, flexible change of installation method.

3. Rail installation is fast and convenient.

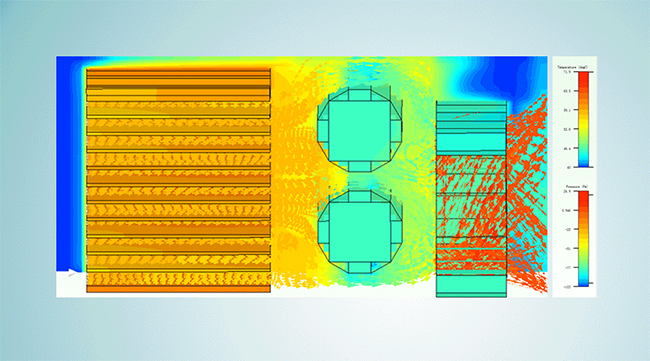

No derating at an ambient temperature of 50℃

Independent air duct design, fast heat dissipation, the low-temperature rise of the machine, no need to derating in a high-temperature environment.

Structural design high protection

1. The air duct is isolated, and the heat is introduced into the air duct after the heating device is processed.

2. Concentrated heat dissipation, electronic sensitive devices are placed in a closed environment to prevent environmental pollution.

Networking design|Hidden line design

1. The group network is convenient to expand, and it can be directly connected through the network port for expansion. Users only need to make a network cable connection, which is convenient and beautiful.

2. The machine is designed with a wire trough on the lower side of the wiring terminal, which can guide the control wiring harness to the wiring trough, and ensure the beautiful wiring in the cabinet and stand-alone use.

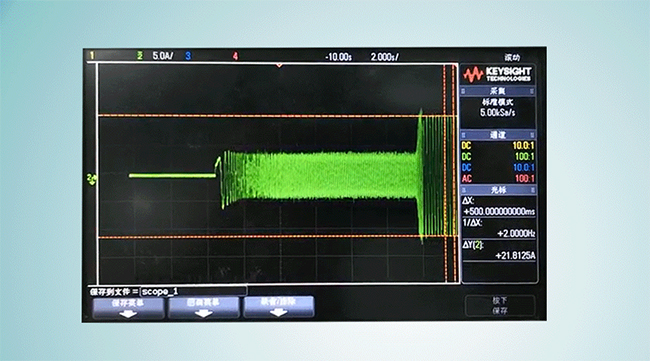

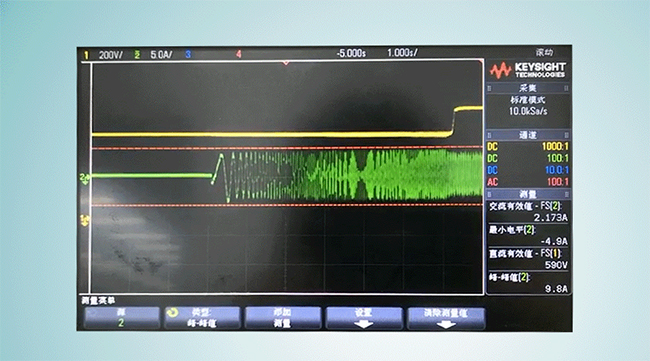

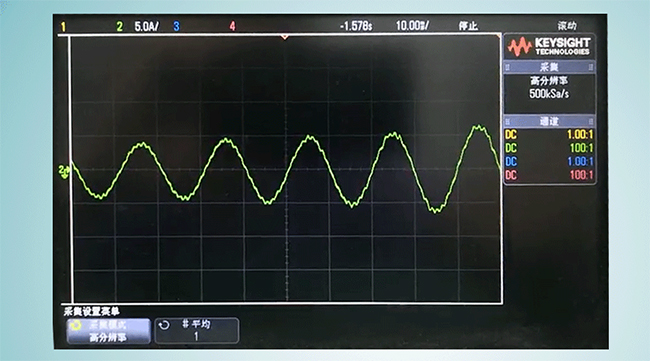

Overcurrent suppression protection

Through real-time monitoring of the load current during operation, it is automatically limited to not exceed the set overcurrent suppression point, which has prevented the fault trip caused by the current. This function is especially suitable for some loads with large inertia or severe changes.

Overvoltage suppression protection

When the bus voltage reaches or exceeds the bus overvoltage suppression point during the operation of the drive, the drive will automatically adjust the operating frequency to suppress the excessive bus voltage, to ensure that the drive does not cause overvoltage protection due to the excessive bus voltage.

Wave-by-wave current limit

When the output current exceeds the wave-by-wave current limit point, the hardware current limit protection is triggered, which can restrain the rise of current to a certain extent so that the current does not exceed the drive protection value, and avoid the current alarm and shutdown due to sudden load or abnormal current.

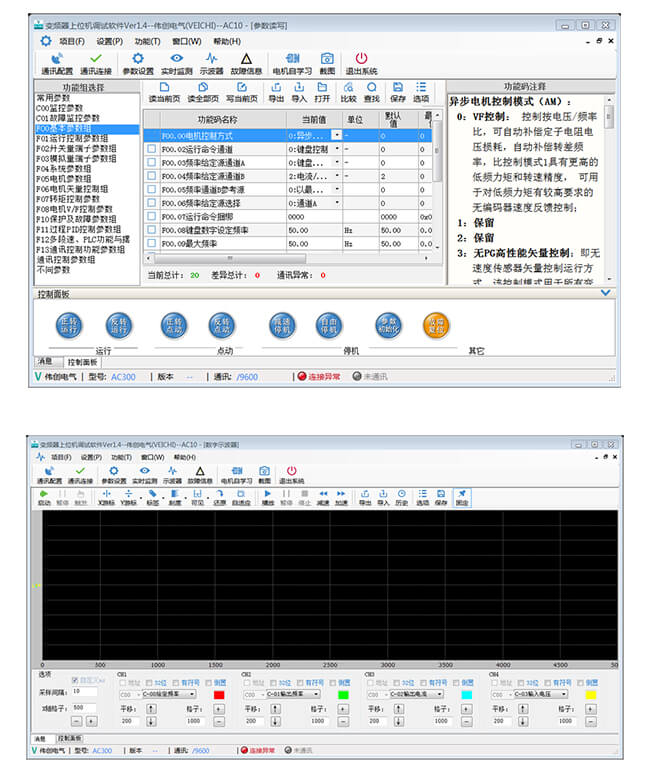

Computer monitoring software

The computer can manage the parameter storage and download of several drives. The parameter download function can save the parameter setting work when exchanging the drive. The monitoring software is equipped with various monitoring, parameter settings, motor self-learning, oscilloscope functions, etc. Only need a simple RS485 serial port, you can simply connect to the computer.

AC10 Series Frequency Variable Frequency Drive AC Drive

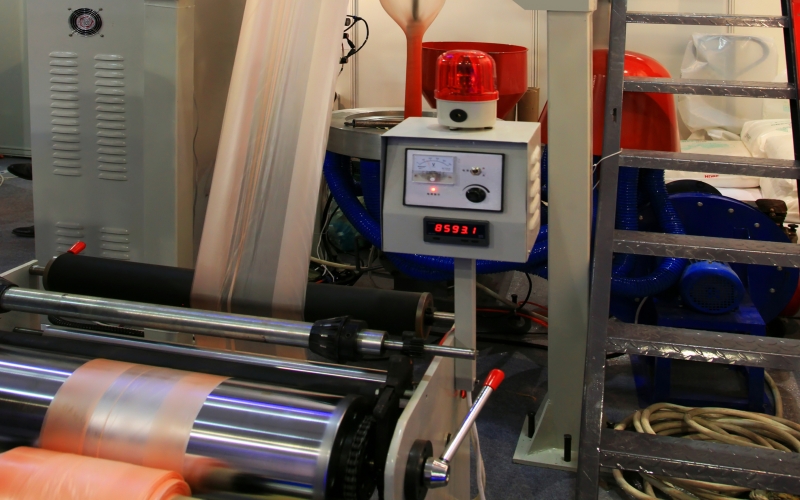

Industrial Applications for AC10 Series Frequency Drive

Application: fan and pump, automated production line, carpentry machinery, smart logistics, food packaging line, and other industries and equipment.

Specifications

| Single phase 220V 50/60Hz | 0.75kW - 2.2kW |

|---|---|

| Three phase 220V 50/60Hz | 0.75kW - 2.2kW |

| Three phase 380V 50/60Hz | 0.75kW - 22kW |

| Voltage and frequency | Single-phase 220V 50/60Hz; Three-phase 380V 50/60Hz; Three-phase 220V 50/60Hz |

|---|---|

| Allow fluctuation | Voltage imbalance rate: <3%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements |

| Closing impulse current | Less than rated current |

| Power factor | ≥0.94 (with DC reactor) |

| Drive efficiency | ≥96% |

| The output voltage | Output under rated conditions: 3-phase, 0~input voltage, error less than 5% |

|---|---|

| Output frequency range | 0~600Hz |

| Output frequency accuracy | ±0.5% of maximum frequency value |

| Overload capacity | T3 model: 150% rated current for 89s, 180% rated current for 10s, 200% rated current for 3s T/S2 model: 150% rated current for 24s, 180% rated current for 3.4s |

| Motor control mode | V/F control without PG, vector control without PG |

|---|---|

| Modulation | Optimize space vector PWM modulation |

| Carrier frequency | 1.0~16.0kHz |

| Speed control range | Vector control without PG, rated load 1:100 |

| Steady-state speed accuracy | Vector control without PG: ≤2% of rated synchronous speed |

| Starting torque | Vector control without PG: 150% rated torque at 0.5Hz |

| Torque response | Vector control without PG: <20ms |

| Frequency accuracy | Digital setting: maximum frequency×±0.01%; analog setting: maximum frequency×±0.2% |

| Frequency resolution | Digital setting: 0.01Hz; Analog setting: maximum frequency×0.05% |

| Torque control | Torque setting calculation, torque mode speed limit |

|---|---|

| DC braking capability | Starting frequency: 0.00~50.00Hz; Braking time: 0.0~60.0s; Braking current: 0.0~150.0% of rated current |

| Torque boost | Automatic torque increase 0.0%~100.0%; manual torque increase 0.0%~30.0% |

| V/F curve | Vector Four methods: linear torque characteristic curve, self-set V/F curve, reduced torque characteristic curve (1.1~2.0 power), square V/F curve |

| Acceleration and deceleration curve | Two ways: linear acceleration and deceleration, S curve acceleration and deceleration Four sets of acceleration and deceleration time, the time unit is 0.01s, the longest is 65000s |

| Rated output voltage | Using the power supply voltage compensation function, the rated motor voltage is 100%, which can be set in the range of 50 to 100% (the output cannot exceed the input voltage) |

| Automatic voltage adjustment | When the grid voltage fluctuates, it can automatically keep the output voltage constant |

| Automatic energy saving operation | Under V/F control mode, the output voltage is automatically optimized according to the load to realize energy-saving operation |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Instantaneous power failure processing | In case of instantaneous power failure, uninterrupted operation is realized through bus voltage control |

| Standard function | PID control, speed tracking and restart after power failure, jump frequency, frequency upper and lower limit control, program operation, multi-speed, RS485, analog output, frequency pulse output, parameter access level setting, common parameter setting, monitoring parameter comparator output , Counting and timing function, swing frequency function |

| Frequency setting channel | Keyboard digital setting, keyboard potentiometer, analog voltage/current terminal AI, communication setting and multi-channel terminal selection, combination of main and auxiliary channels, which can be switched in various ways |

| Feedback input channel | Keyboard potentiometer, voltage/current terminal AI, communication setting, pulse input PUL |

| Run command channel | Operation panel setting, external terminal setting, communication setting |

| Input command signal | Start, stop, forward and reverse rotation, jog, multi-speed, free stop, reset, acceleration and deceleration time selection, frequency setting channel selection, external fault alarm |

| External output signal | 1 relay output, 1 collector output, 1 AO output can be selected as 0~10V or 0~20mA or 4~20mA output |

| Protective function | Overvoltage, undervoltage, current limit, overcurrent, overload, electronic thermal relay, overheating, overvoltage stall, data protection, fast protection, input and output phase loss protection |

|---|

| LED display | Built-in keyboard: single-line 5-digit digital tube display, it can monitor the status of 1 drive External keyboard: dual-line 5-digit digital tube display, it can monitor the status of 2 drive |

|---|---|

| Parameter copy | The function code information of the drive can be uploaded and downloaded to realize fast parameter copy (only external keyboard) |

| Error alarm | Overvoltage, undervoltage, overcurrent, short circuit, phase loss, overload, overheating, overvoltage stall, current limit, data protection damaged, current fault operating status, historical fault |

| Installation site | If the altitude is lower than 1000 meters, derating for use above 1000 meters, derating by 1% for every 100 meters No condensation, icing, rain, snow, hail, etc., solar radiation less than 700W/m2, pressure 70~106kPa |

|---|---|

| Temperature and humidity | from -10℃ to +50℃, derating can be used above 40℃, the maximum temperature is 60℃ (no-load operation) 5% ~ 95%RH(No condensation) |

| Storage temperature | -30 ~ +60℃ |

| Installation method | Wall-mounted |

| Protection class | IP20 |

| Cooling method | Forced air cooling |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message