Flying Shear System Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Flying Shear System Solution

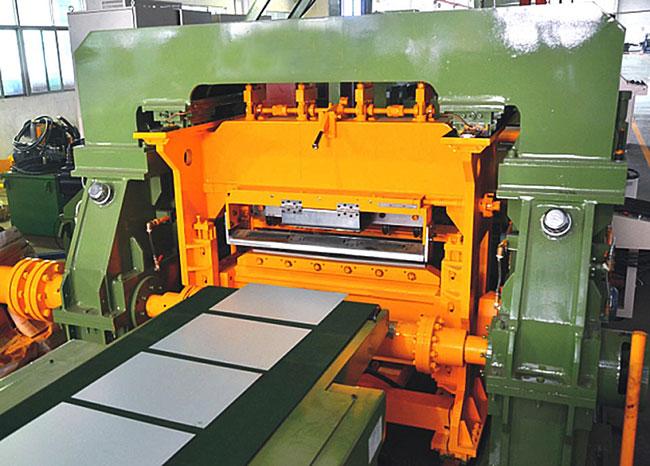

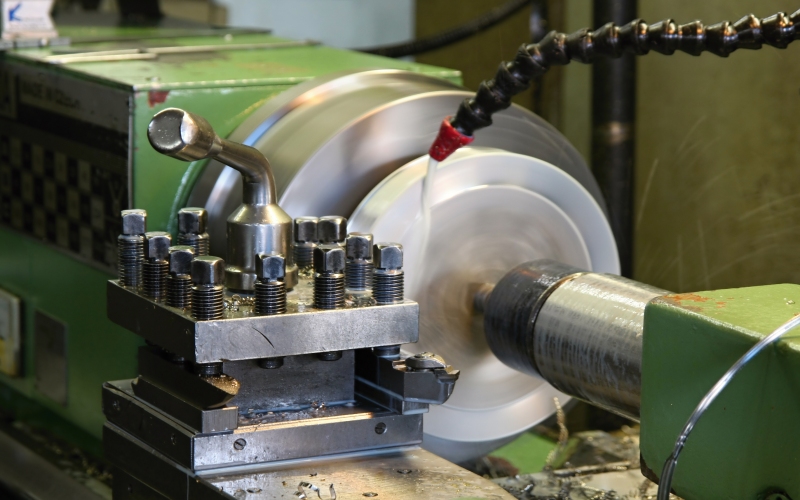

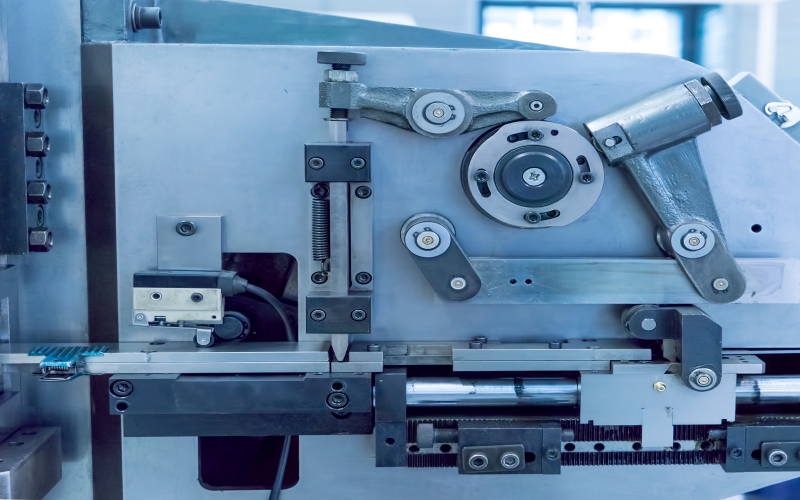

The flying shear system is a material cutting and processing system that feeds and cuts at the same time. It performs synchronous cutting during the material feeding process to achieve the purpose of high-precision cutting without stopping the machine. The flying shear system is widely used in all kinds of equipment. For example, shearing machines, printing machines, rotary cutting machines, and packaging machines all use flying shear systems. The core working principle of this kind of mechanical equipment is the main shaft with the feeding shaft as the electronic cam function. The control part calculates the movement curve of the slave shaft according to the real-time position of the main shaft and sends it to the slave shaft for execution. The slave shaft completes the flying shear according to the position of the curve. sports.

Features and Benefits

Introduction

Shears are the most widely used sheet cutting equipment in various industrial sectors and are currently widely used in steel, printing, and cardboard processing industries. The shearing machine performs synchronous cutting during the material feeding process to realize high-precision cutting without stopping. The flying shear control system is the key to the shearing machine. The quality of its product control performance directly affects the product yield.

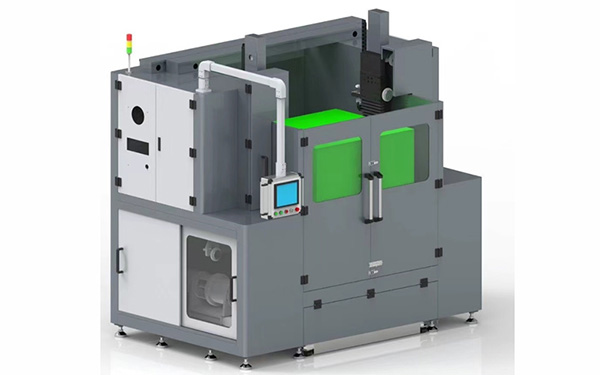

VEICHI flying shear control system provides special servos for flying shears with power ranging from 50W to 200KW, which can provide customers with the best solutions according to the different application sites of customers. At present, we have a flying shear system solution with the V5 motion controller as the main control core of the flying shear. At the same time, for some special projects, VEICHI also provides a dedicated servo flying shear solution with SD700 flying shear dedicated servo as the main control core for a variety of options.

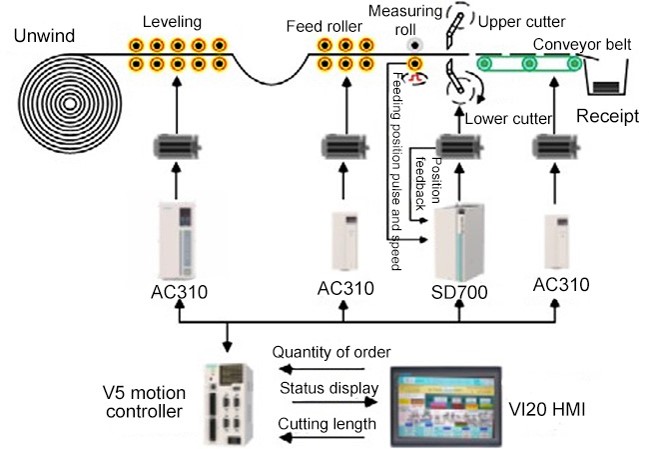

System topology

The overall solution of the VEICHI flying shear control system is composed of one 55KW flying shear servo, one 45KW leveling inverter, one 7.5KW feeding inverter, one 4KW conveyor belt inverter, one motion controller, and one touch screen. . The theoretical value of the maximum spindle speed when processing long materials can reach 200m/min, and the theoretical value of the maximum spindle speed when processing 0.5m short materials can reach 150m/min, and the material cutting accuracy is stable within ±0.12mm.

The VEICHI flying shear control system solution can realize high-speed operation while ensuring stable operation error within ±0.12mm, and realize the synchronization of the master and slave axis position and high-speed response servo motor control through the 5-fold curve planning of the electronic cam. It has realized the advantages of high speed, large width, high efficiency, and high reliability of the flying shear system. Finally, the actual production requirements of high-speed, high-precision, and high stability of the shears are realized.

Program highlights

1. The SD700 flying shear servo drive has built-in electronic cam calculation functions, including flying shears and tracking shears electronic cam functions, which can be directly connected with the man-machine interface to achieve centralized control, stable performance, easy operation, and easy maintenance.

2. All parameters are displayed and modified in real-time by the man-machine interface, which can display the speed of the feeding shaft, the cutting length, and the number of orders. It also includes multiple order modes, with a maximum order mode of 8, and supports switching between recurring mode and single-mode.

3. The system can automatically calculate the maximum speed of the corresponding feeding shaft according to the set cutting length and then use the motion controller to limit the maximum speed of the entire system to avoid running out of trouble.

4. The flying shear system can automatically calculate the number of processed orders. When the actual order quantity is close to the set total order quantity, it can automatically output the output close signal to the motion controller, and the motion controller adjustment system decelerates in advance. Avoid emergency stops during normal processing and improve the safety of the system.

5. The system has an automatic material receiving function. In the automatic material receiving mechanism, materials can be automatically collected according to the order setting, and it also has a material counting function. When the number of materials collected reaches the set value, the system will automatically stop processing, and then wait for the number of the receiving mechanism to be cleared and run the system again for processing.

Process principle

The structure of the flying shear system is mainly composed of the following parts:

1. Uncoiling and leveling mechanism: Driven by a 45KW VEICHI AC310 series inverter, the metal plate conveyed by the unwinding mechanism is pressed and leveled.

2. Feeding roller mechanism: Driven by a 7.5KW VEICHI AC310 series inverter to achieve the purpose of feeding, it is required to ensure a stable feeding speed and high responsiveness.

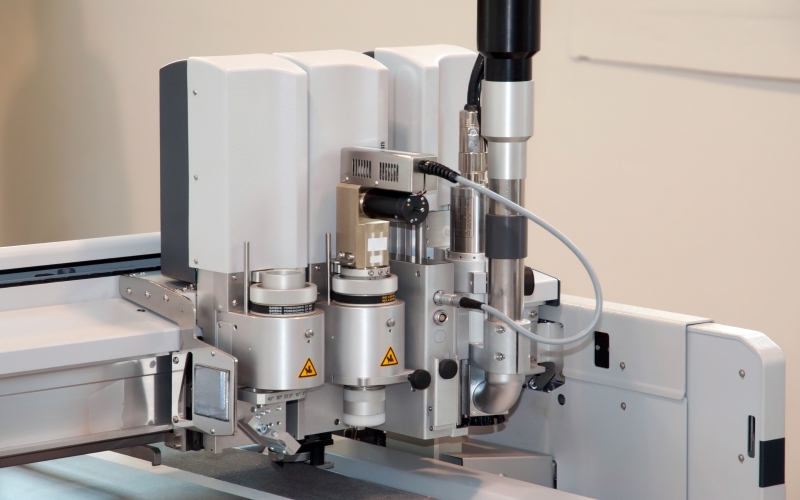

3. Measuring roller mechanism: The real-time position and real-time speed of the feeding roller are collected through an external encoder and sent to the flying shear servo drive for data processing.

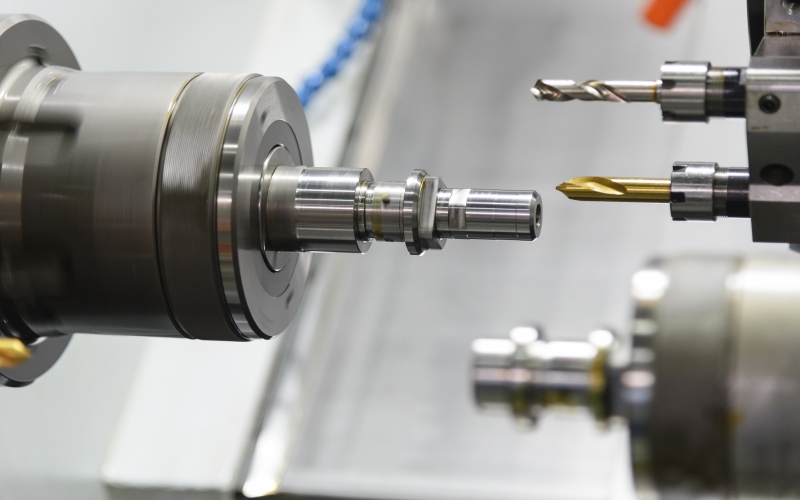

4. Cutter shaft mechanism: Driven by a 55KW VEICHI SD700 series special servo drive for flying shears, the speed and position are calculated based on the pulses collected by the measuring roller structure, and the flying shear curve is automatically planned inside the drive according to the flying shear algorithm. Drive the flying shear head to complete the flying shear action.

5. Conveyor belt mechanism: It is mainly used to convey the cut orders to ensure that the materials enter the receiving mechanism in an orderly and orderly manner. The rear section can be equipped with packaging equipment such as balers to make the production process of products more efficient and intelligent.

Rich functions and fast processing speed

The cutter axis is driven by the VEICHI SD700 series 55KW high-power flying shear servo drive, and the SD700 series Servo System adopts the bottom layer of the dual CPU hardware architecture, which has a faster processing speed. Built-in electronic cam calculation function, including flying shear, tracking shear electronic cam function, can be directly connected with the man-machine interface to achieve centralized control. Stable performance, easy to operate, easy to maintain, and the operating interface of the flying shear system can be switched between Chinese and English.

SD700 Product Features

Support multiple working modes

All parameters are displayed and modified in real-time by the man-machine interface. It can display the speed of the feeding shaft, the cutting length, and the number of orders, and includes multiple order modes, with the maximum order mode reaching 8, and it supports switching between cyclic mode and individual mode.

Effectively reduce the defect rate

The system can automatically calculate the maximum speed of the corresponding feeding axis according to the set cutting length, and then limit the maximum speed of the entire system through the motion controller. Avoid running out of trouble, improve system safety, and reduce product defect rates.

Effectively reduce the defect rate

Improve system security

The system can automatically calculate the number of processed orders. When the actual order quantity is closing to the set total order quantity, it can automatically output the output close signal to the motion controller. The motion controller adjusts the system to decelerate in advance to avoid emergency stops during normal processing and improve the safety of the system.

Improve system security

Guaranteed abnormal downtime

The system has the function of saving the order quantity. If an abnormal shutdown is caused by improper operation or power failure, the system will run again, and it will automatically process from the last memorized order. And the system has a patrol stop function to ensure that the cutter can stop at the position of 180° every time, which can effectively protect the cutter from being damaged when it stops abnormally.

Guaranteed abnormal downtime

Integrated control is more worry-free

The system has an automatic material receiving function, and the material can be automatically collected according to the order set in the automatic material receiving mechanism. At the same time, it has a material counting function. When the number of materials collected reaches the set value, the system will automatically stop processing, and then wait for the number of the receiving mechanism to be cleared and run the system again for processing.

Integrated control is more worry-free

The VEICHI flying shear system solution can be adjusted according to customer needs. It has many advantages: high efficiency, good stability, strong anti-interference ability, and a wide range of applications. It has been maturely applied in a variety of industrial equipment on the market. In the future, VEICHI will continue the concept of "guided by market demand, driven by technological innovation ", and will focus more on the polishing of details to provide customers with high-quality products and perfect solutions. We are constantly striving to advance to promote the high-quality development of the electric drive and industrial control industries.

Technical index

For processing long materials, the maximum spindle speed can reach 200m/min.

For processing 0.5m short materials, the maximum spindle speed can reach 150m/min.

The maximum order mode reaches 8 and it supports switching between recurring mode and single-mode.

The cutting accuracy is stable within ±0.12mm.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message