Fixed-length Cutting Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Fixed-length Cutting Machine Solution

With the development of modern industry, some high-precision control places have higher and higher requirements for servo control. However, due to the limitation of the mechanical transmission part, the traditional semi-closed loop servo control method has gradually been difficult to meet the requirements for precision control. In order to meet market demand, VEICHI introduced a fully closed-loop servo driver with a new and improved algorithm, which can effectively avoid the impact of mechanical transmission on the final control accuracy of the equipment. Since the introduction of fully closed-loop servo drives, a large number of successful applications have been obtained in the market.

Features and Benefits

Introduction

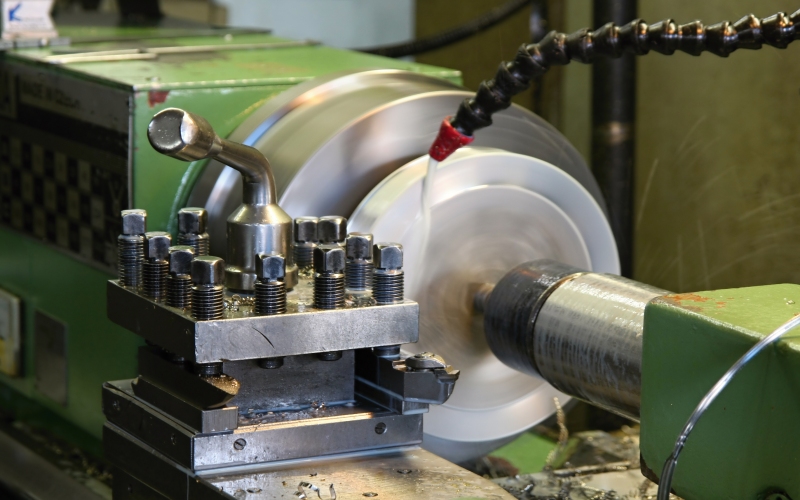

The feeding mechanism of the punching machine requires high precision for servo control, and the traditional semi-closed loop scheme is difficult to achieve high control performance. Recently, the application development team of VEICHI received a task to transform the feed mechanism of the drawer slide forming machine. After receiving the task, the VEICHI team quickly formulated a preliminary solution and carried out a feasibility analysis, and finally formulated a set of fully closed-loop solutions, which perfectly solved the problems of low accuracy and low efficiency of customer equipment.

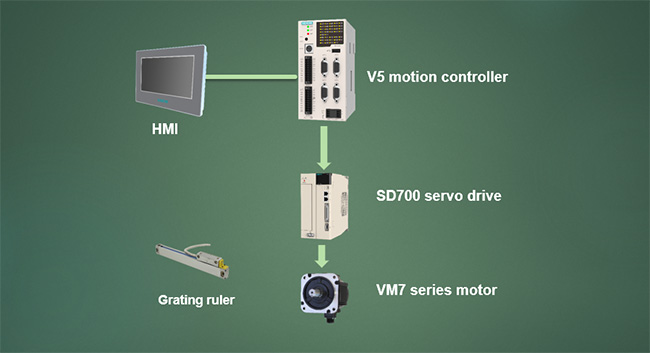

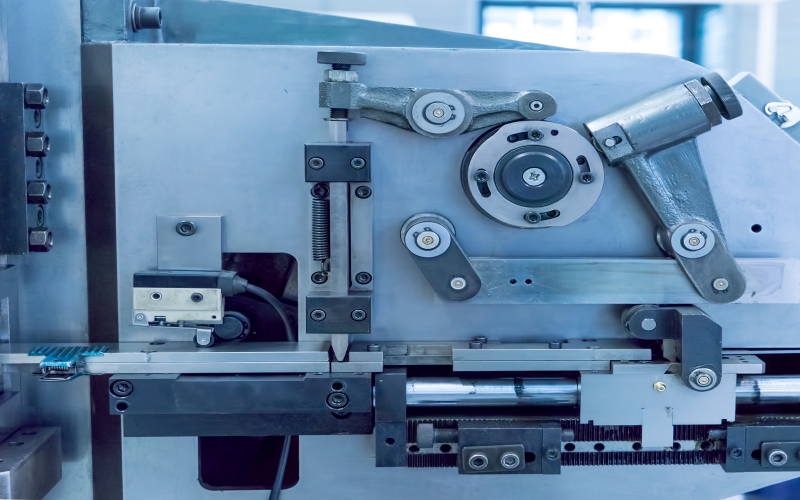

System topology

Disadvantages of the old feeding mechanism

-

For cost considerations, the customer's mechanical transmission part is driven by a chain and a gear reducer. Such a transmission mechanism will cause a large error, which directly leads to the failure of the product.

-

The customer will automatically complete the error correction function in the PLC. Because the judgment and correction of errors require continuous collection errors and calculation compensation, it leads to a very low production efficiency of the entire system.

-

Because the full-closed loop function is placed inside the PLC, the debugging of the entire system becomes very troublesome, there are many compensation parameters, and it is troublesome for the operator to operate.

Solution given by application development team of VEICHI

-

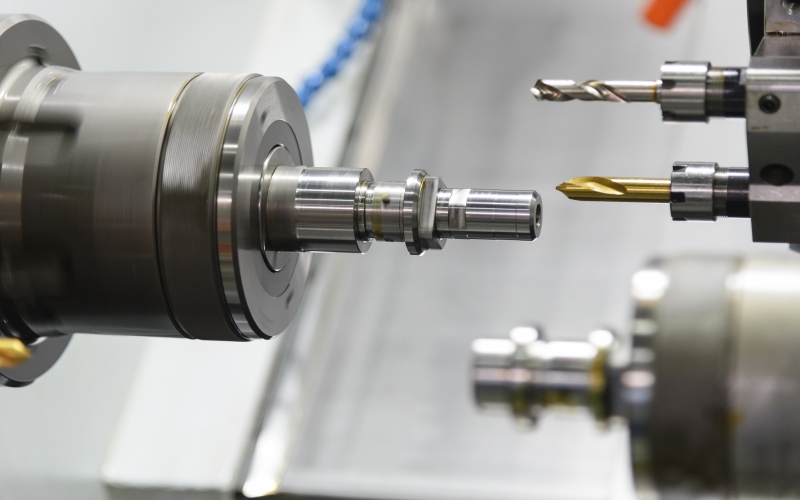

The servo is replaced with the new fully closed-loop algorithm SD700 servo drive of VEICHI to complete the feeding control. All full-closed loop algorithms are completed by the servo drive, which not only improves the machining accuracy but also further improves the machining efficiency.

-

The electronic control part uses a touch screen integrated machine to complete the control, further reducing costs for customers and increasing market competitiveness.

- Add multiple safety protection measures (servo judgment procedures, positioning jitter judgment procedures, etc.) to ensure the safety of operators and equipment as much as possible in the procedures.

Performance comparison between equipment after transformation and before modification

-

1. The processing efficiency is increased by more than 50%, and the cutting speed of the guide rail of 10 cm has reached 50 pieces / min, far exceeding the previous processing speed.

-

2. Due to the use of the full closed-loop function of the servo drive, the processing accuracy of the equipment reaches ± 0.01mm, which has improved by more than an order of magnitude compared to the previous ± 0.3mm.

-

3. Compared with the touch screen and PLC of the old scheme, the cost of using the touch screen all-in-one solution is reduced by at least 30%.

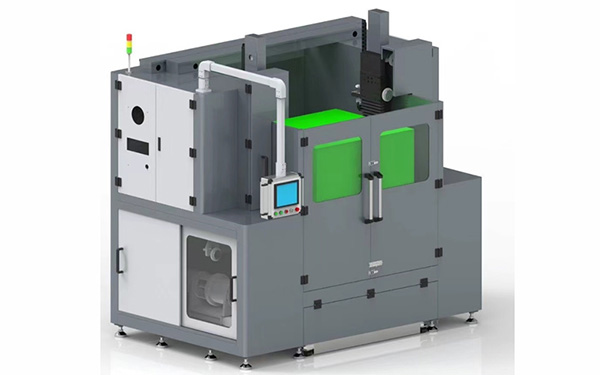

Application of SD700 full-loop function on fixed-length cutting machine

Program highlights

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. The connection between the V5 controller and the servo drive adopts high-speed differential signals, which have high stability and are not susceptible to interference. The maximum pulse speed of the differential pulse port is 3MHz, which can achieve extremely high control accuracy;

4. Adopt the servo drive full closed-loop solution, which perfectly solves the problem of low accuracy and low efficiency of customer equipment.

Process principle

1. The servo is replaced with the SD700 servo drive of VEICHI new full-closed-loop algorithm to complete the feeding control, and all the full-closed-loop algorithms are completed by the servo drive. While improving the processing accuracy, it also further improves the processing efficiency.

2. The electrical control part uses a touch screen integrated machine to complete the control, which further reduces costs for customers and increases market competitiveness.

3. Add multiple safety protection measures (servo judgment program, positioning jitter judgment program, etc.) to ensure the safety of operators and equipment as much as possible in the program.

Technical index

The cutting speed of the 10 cm guide rail has reached 50 per minute.

The machining accuracy reaches ±0.01mm.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message