Cutting Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

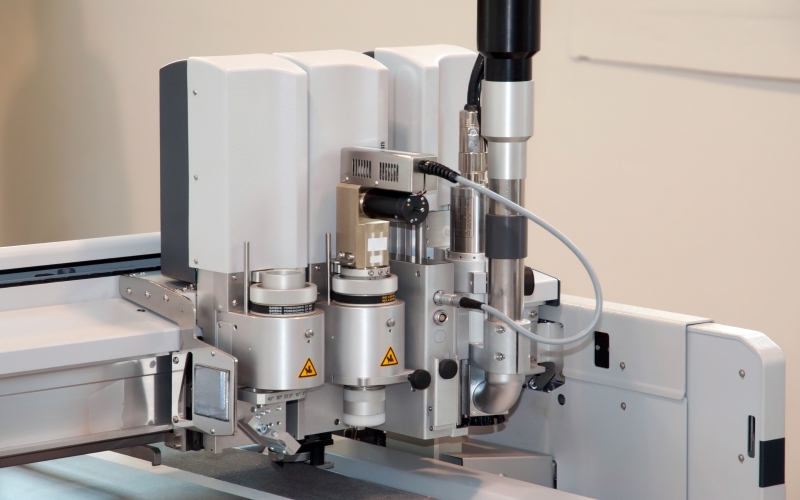

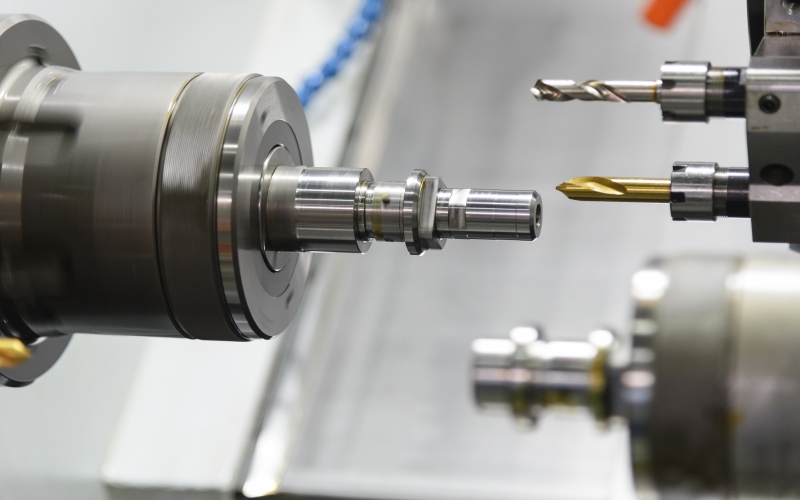

Cutting Machine Solution

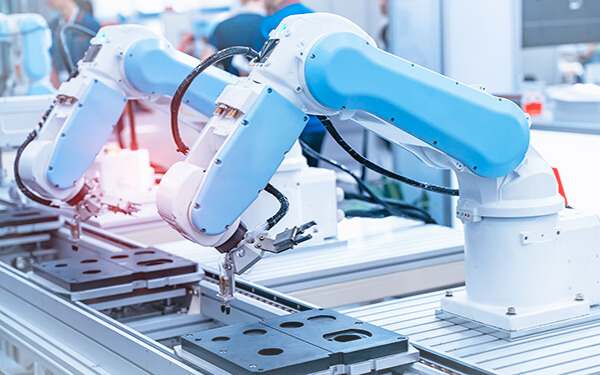

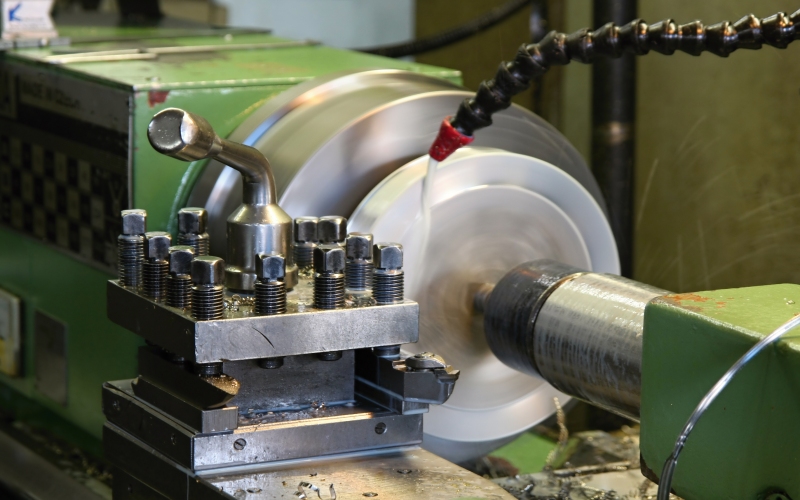

With the rapid development of the times and the rapid advancement of the furniture industry, more and more panel furniture appear in people's home life. The panel furniture production line of CNC woodworking machinery and equipment has also emerged, and the efficient processing method can not only increase the processing speed but also better improve the processing quality. The CNC cutting machine in the panel furniture production line is the core of science and technology. The CNC cutting machine realizes vertical hole drilling, slotting, blanking, free processing of special-shaped panels, and easy realization of customized panel furniture production.

Features and Benefits

Introduction

The panel furniture production line of CNC woodworking machinery and equipment has also emerged, and the efficient processing method can not only increase the processing speed but also better improve the processing quality.

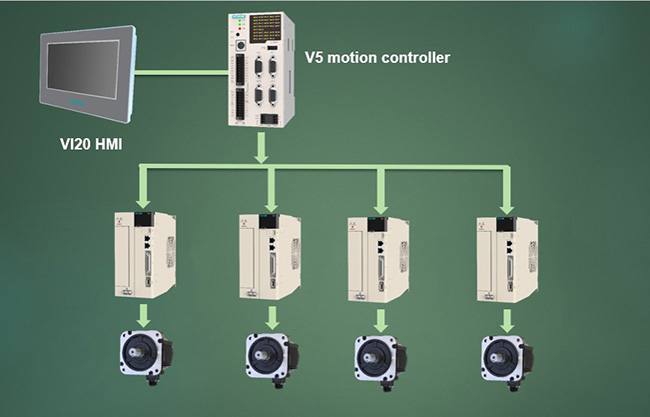

System topology

Program highlights

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. The connection between the V5 controller and the servo adopts a high-speed differential signal, which has high stability and is not susceptible to interference. The differential pulse port has a maximum pulse speed of 3M, which can achieve extremely high control accuracy.

4. Save labor and materials: With the CNC cutting machine, one person can complete the cutting and punching work, which greatly improves the utilization efficiency of the board.

5. Time-saving: the efficiency of the CNC cutting machine is very high, and the production efficiency is greatly improved.

6. Possess strong special-shaped processing ability, which is very suitable for customized production. To meet customers' customized and diversified needs.

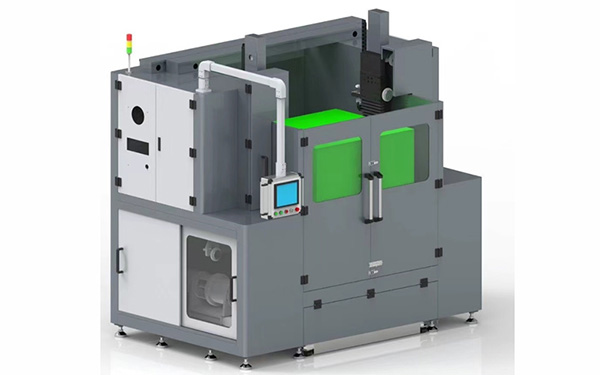

Process principle

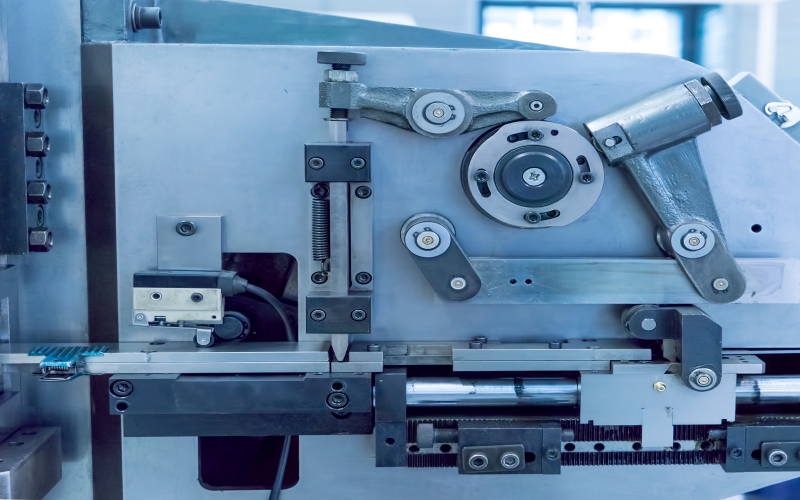

The system consists of the upper computer man-machine interface, control system, and servo drive. Through the bus connection, the control system plans the relevant motion trajectory. One high-speed spindle processes the plate, and the other 3 axes realize the position control of the plate.

Technical index

Repeat positioning accuracy meets ±0.02mm.

The maximum processing speed is 25m/min.

It supports two-axis circular interpolation and three-axis linear interpolation.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message