Paper Towel Slitting Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Paper Towel Slitting Machine Solution

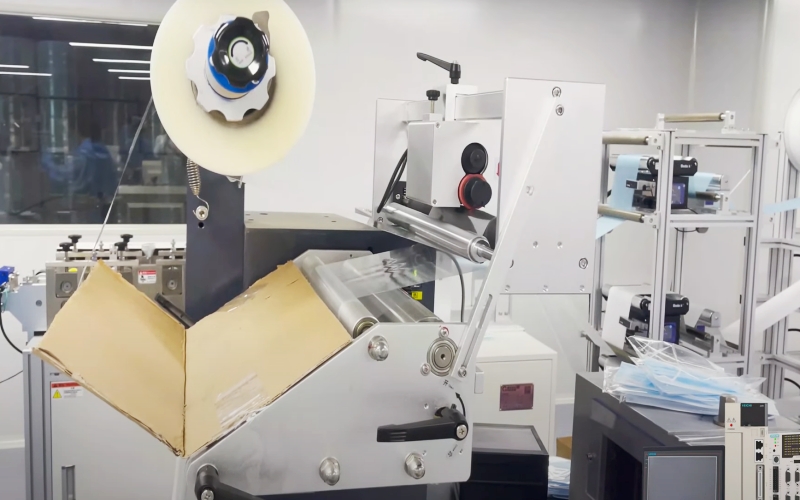

The pumping paper and wet tissue paper used in daily life are all short strips, and they are first a few meters long strips, which are cut by a paper cutter before being packed into bags for everyone to use.

Features and Benefits

Introduction

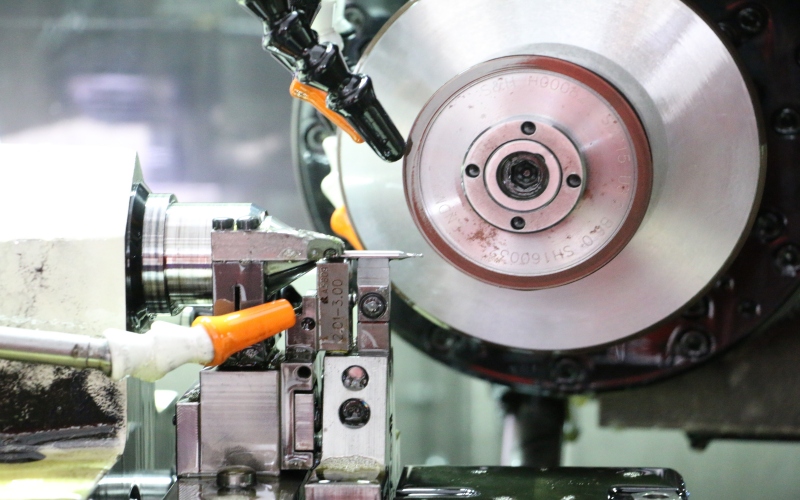

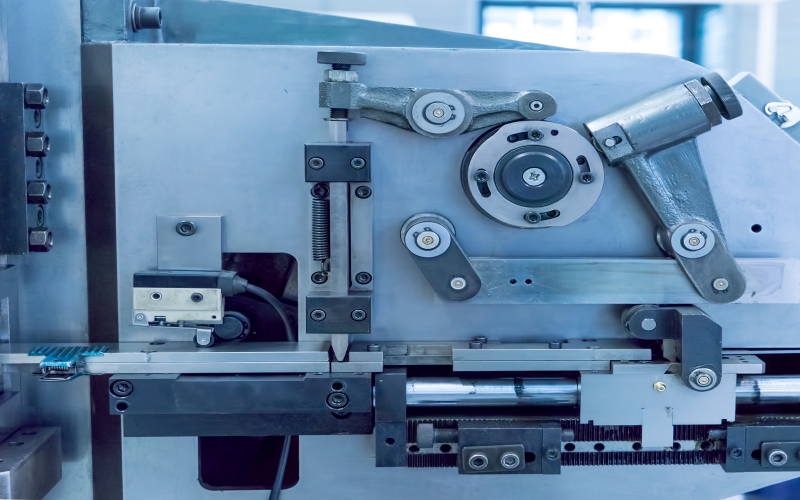

This machine is used for automatic cutting of non-woven fabrics, cotton soft towels, facial tissues, etc., cutting long sections of materials into small sections of a set length, and packaging them into bags for the back-end process.

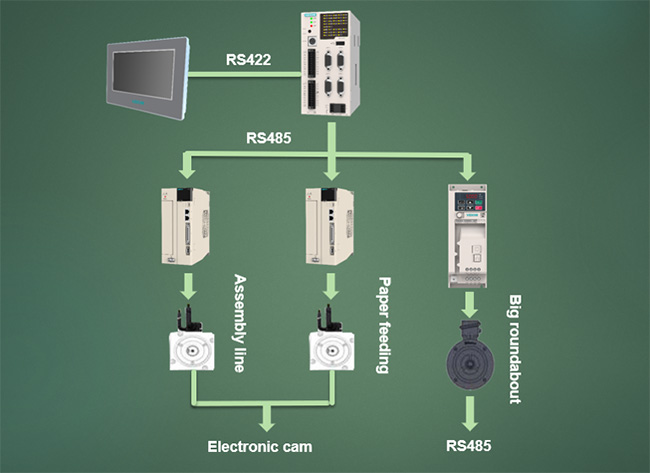

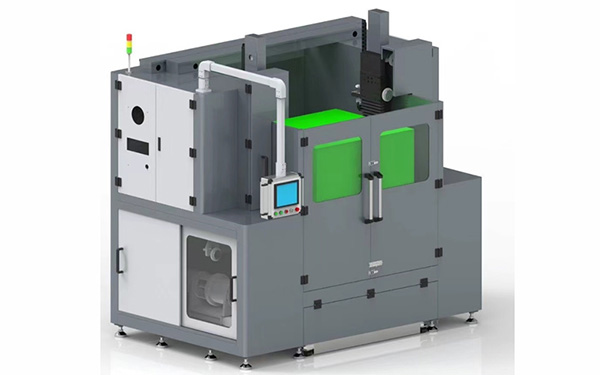

System topology

Program highlights

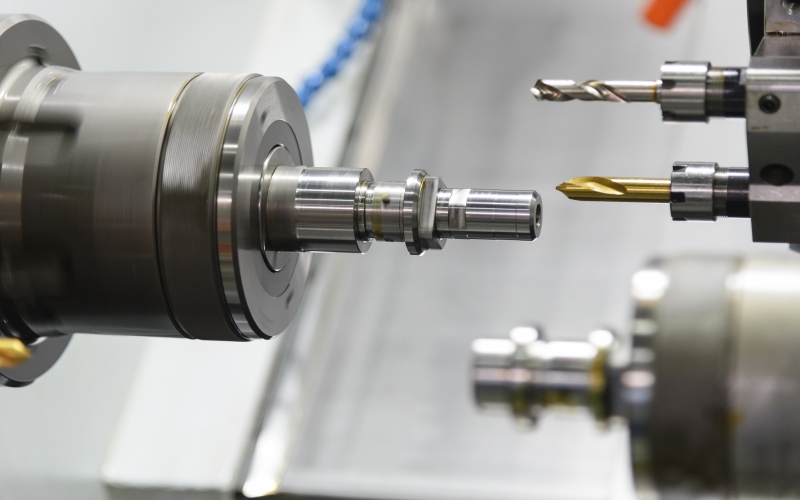

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. The electronic cam guarantees softness and accuracy, supports continuous feeding and interval feeding modes.

4. The connection between the V5 controller and the servo adopts a high-speed differential signal, which has high stability and is not susceptible to interference. The maximum pulse speed of the differential pulse port is 3M, which can achieve extremely high control accuracy.

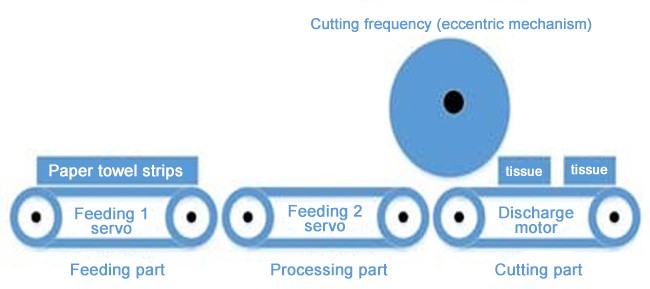

Process principle

The long section of material is sent to the feeding belt, and the feeding belt sends it to the processing section. The belt in the processing section performs precise feeding synchronously with the intermittent cutting of the rotary cutter controlled by the frequency converter. The small pieces of material after the rear end slitting are sent out through the feeding belt for direct packaging and use by the rear end equipment.

Technical index

Cutting speed 200 packs/min (material length 200mm).

Slitting accuracy ±0.5mm.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message