Inclined Lathe Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

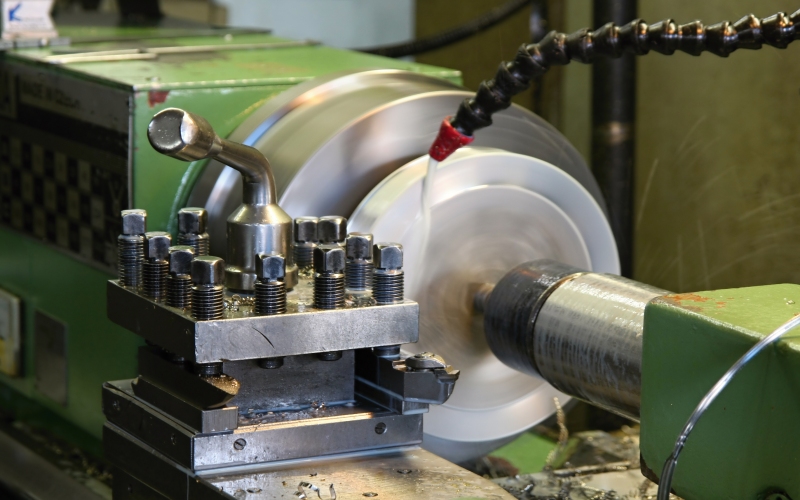

Inclined Lathe Solution

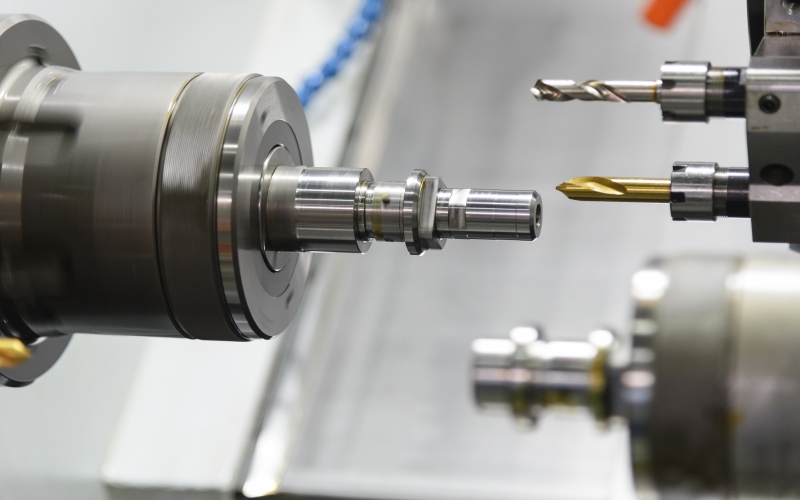

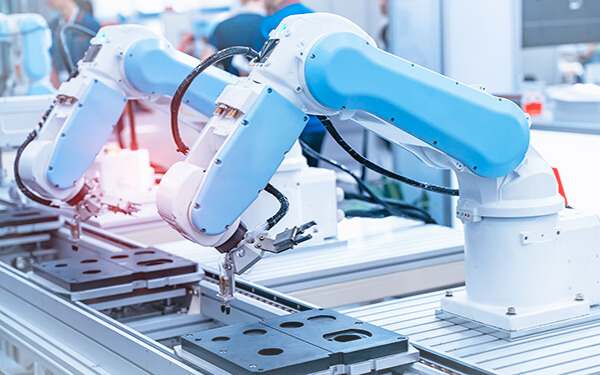

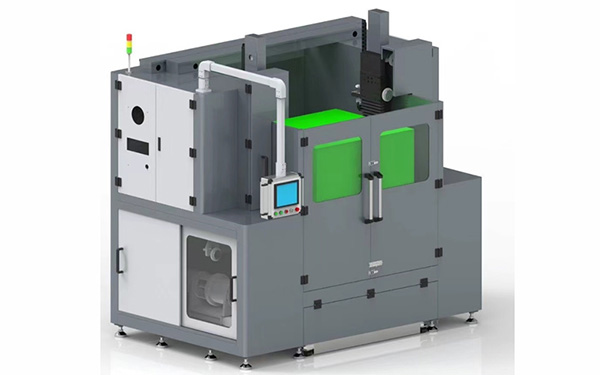

The inclined bed CNC lathe is a high-precision and high-efficiency automatic machine tool. Equipped with a multi-station turret or a power turret, the machine tool has a wide range of technological performance, which can process linear cylinders, oblique cylinders, arcs and various threads, grooves, worms and other complex workpieces. Compensate various compensation functions, and play a good economical effect in the mass production of complex parts. When the CNC lathe with inclined bed is used for cutting in practice, it has the function of optional dynamic tool and 8-station turret tool holder, so it can play an important role in the processing of different products, especially in complex and high-precision machining.

Features and Benefits

Solution advantages

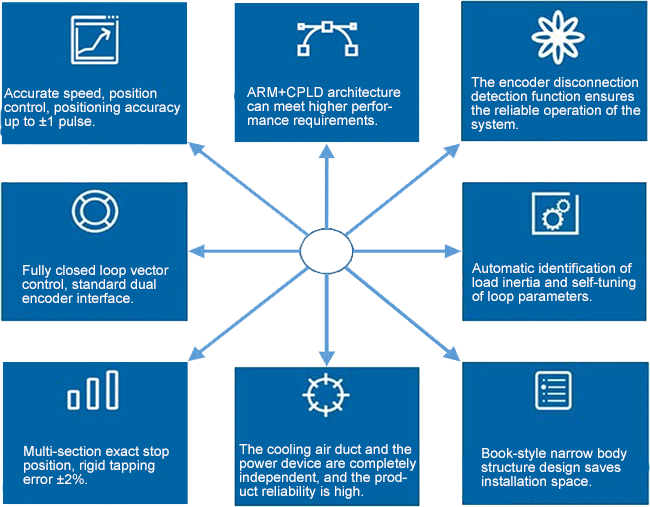

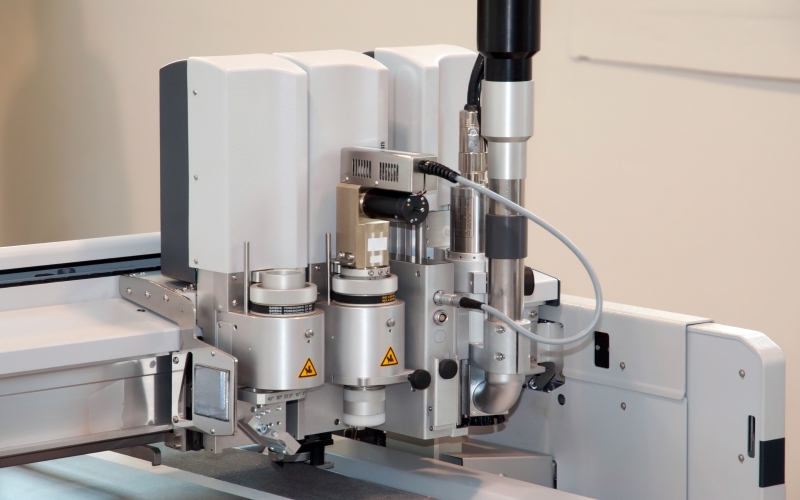

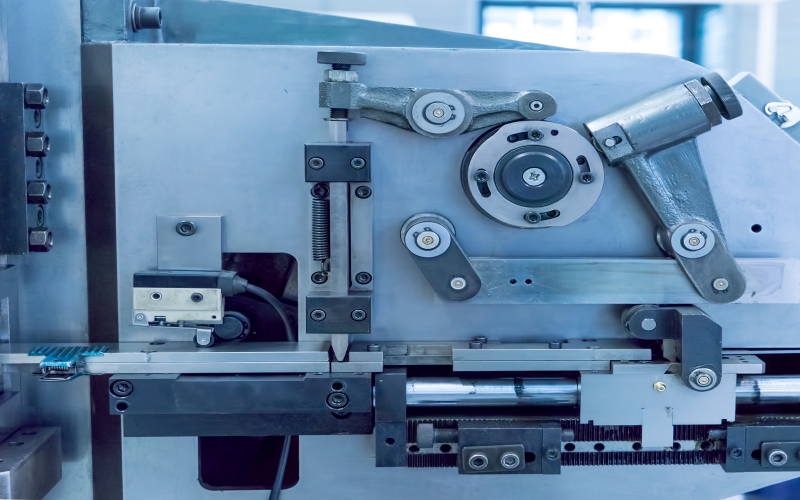

1. The feed axis and powerhead servo support multiple bus protocols (MECHATROLINK-II bus, MECHATROLINK-III bus, EtherCAT bus), the powerhead dedicated servo motor has a large output, the maximum speed can reach 6000 rpm, and the output plane is smoother.

2. The spindle servo is equipped with dual PG as standard, and at the same time, it has a motor encoder and a spindle encoder to achieve full closed-loop control with high control accuracy.

3. The spindle frequency converter is integrated with asynchronous drive, comprehensive open and closed loops, low speed and large torque, and excellent acceleration and deceleration response capabilities.

4. Equipped with various systems, the processing speed is stable, the processed workpiece has a fine texture and high smoothness.

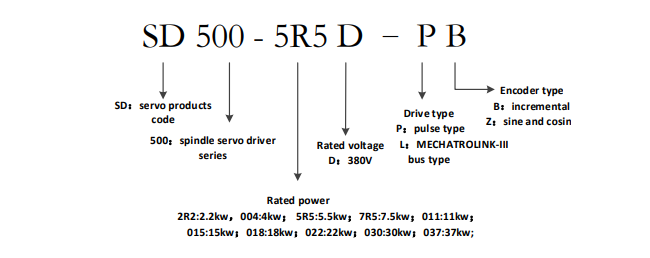

Spindle servo drive model

Spindle servo characteristics

System topology

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message