- Home > Product > Industry-specific Drive > Machine Tool > SD500 Spindle Servo Srive

SD500 Spindle Servo Srive

- Accurate speed, position control, positioning accuracy of ±1 pulse

- Powerful self-learning function

- Multi-stage quasi-stop position, rigid tapping error ±2%

- One-point setting at zero position, easy to operate

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

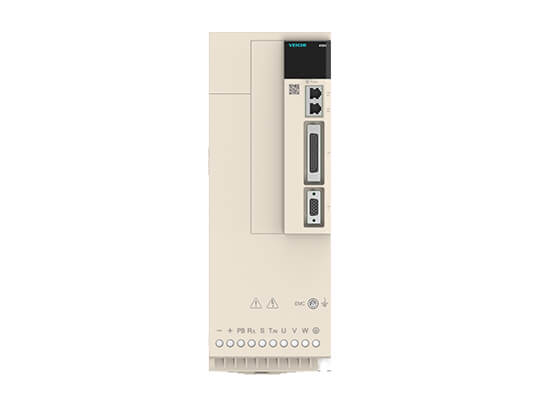

SD500 Spindle servo drive Overview

SD500 is a new generation of high-performance spindle servo drive. The standard dual-encoder interface can realize the full-closed-loop servo control of the spindle motor. It integrates speed control, position control and torque control. Precise position control and enhancement of product environmental adaptability and customized and industrialized design provide excellent drive solutions for machine tool spindles.

1. Dual encoder: dual encoder interface, full closed-loop vector control.

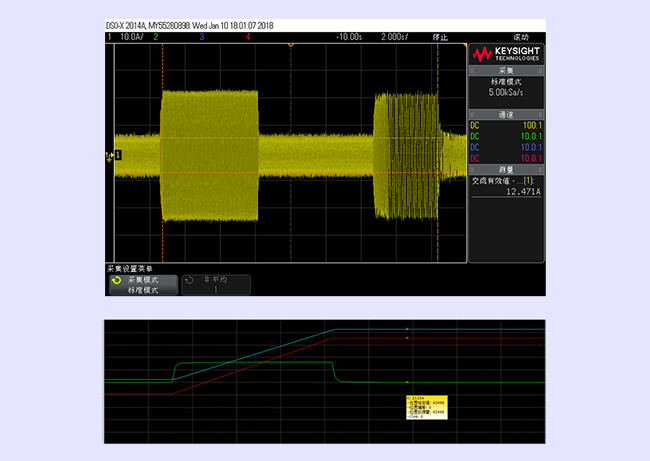

2. Quick response: strong load response capability.

3. Parameter optimization: self-tuning of loop parameters.

4. Wide range: large low-frequency torque, wide speed range.

5. Strong stability: accurate positioning and simple debugging.

6. Support the open-loop and closed-loop: Integrate synchronous and asynchronous drive.

High-performance spindle servo drive

SD500 is a new generation of high-performance spindle servo driver developed by VEICHI. It is equipped with dual-encoder interfaces as standard, which can realize full-closed-loop servo control of the spindle motor. It integrates speed control, position control, and torque control; it strengthens the environmental adaptability, as well as customized and industrialized design, to provide excellent drive solutions for machine tool spindles.

Strong self-learning ability

1. It supports open-loop and closed-loop vector control, integrating synchronous and asynchronous driving.

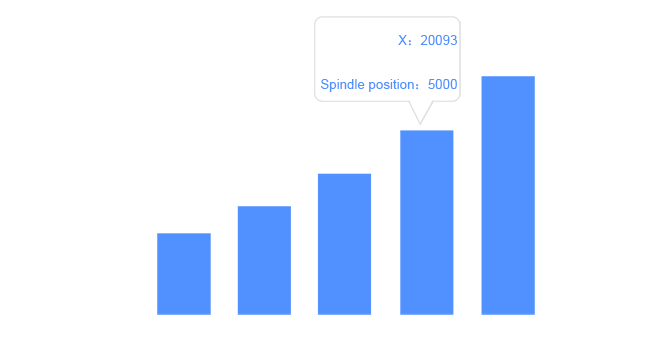

2. Accurate speed and position control, positioning accuracy can reach plus or minus 1 pulse.

3. Powerful self-learning function: motor parameters, encoder, system inertia, and speed loop parameters self-tuning.

4. Wider constant torque output platform, stronger field weakening ability to increase speed.

Triple protection design, strong environmental adaptability

1. Multi-stage exact stop position, rigid tapping error is plus or minus 2%.

2. The zero position is set by one button, which is convenient for operation.

3. Hardware current limit, strong overload capacity, adapt to various harsh working conditions.

4. Eighty kinds of failure protection, comprehensive protection of product safety.

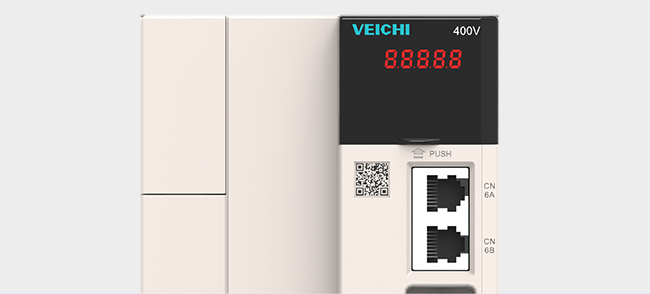

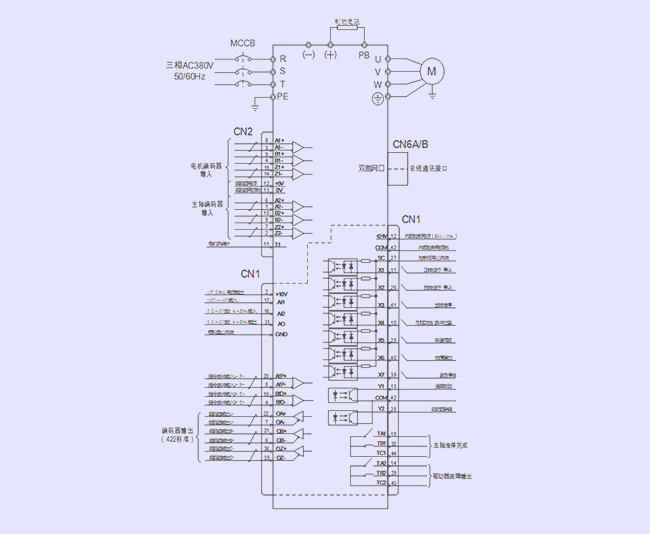

Rich wiring ports

1. 6-way switch + 1 way to tell switch input.

2. 2 collector outputs + 2 relay outputs.

3. 1 bipolar analog input + 1 unipolar analog input + 1 analog output.

4. 2 encoder inputs + 1 high-speed command pulse input + 1 arbitrary frequency division differential output.

5. Equipped with 5V, 10V, 24V external power supply.

High-precision control, proficient in every 18 kinds of "martial arts"

1. Position control, speed control, torque control.

2. Asynchronous motor/synchronous motor/V/F, open-loop vector, closed-loop vector control.

3. Multiple pulses setting modes.

4. Inertia identification, self-tuning of loop parameters.

5. 8 indexing precise stop control.

6. Position swing.

7. Zero-point one-key setting.

8. PID control and so on.

All-in-one superior performance to create a star product of VEICHI

1. Perfect current vector control algorithm.

2. The speed range is wide, and the speed pulsation is small at super high speed.

3. Safe and reliable hardware equipment.

4. The position control has a fast response and high precision.

5. Excellent frequency conversion energy-saving control.

6. The torque is controlled accurately and the output is stable.

7. The low-frequency torque is large and the speed is stable.

8. Good load dynamic and static response control.

SD500 Spindle Servo Drive Video

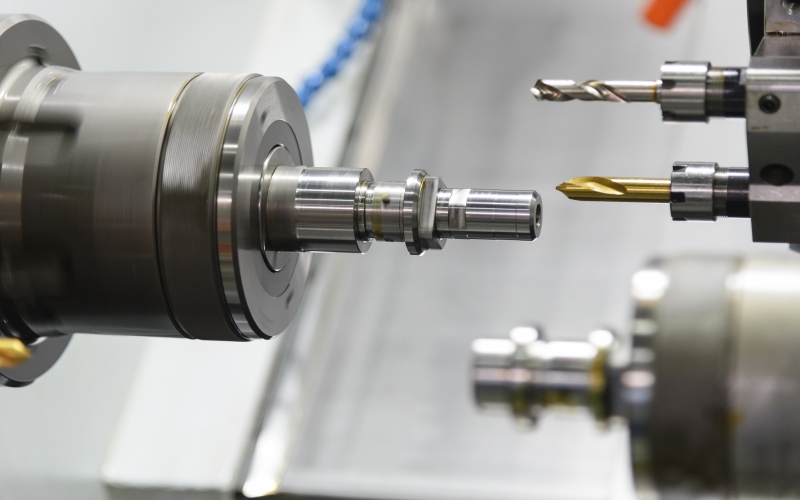

Industrial Applications for SD500 Spindle Servo Drive

Applications:Used in industries and equipment such as CNC machine tools, electronics manufacturing, textile machinery, printing and packaging, die-cutting machines, and woodworking machinery.

Specifications

| Power range | 4,000 W-37,000 W |

|---|

| Voltage frequency | Three phases: 380V ~ 440V, 50/60Hz |

|---|---|

| Allow fluctuations | Voltage imbalance rate: <3%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements |

| Closing surge current | Less than rated current |

| Power factor | ≥0.94 (with DC reactor) |

| Frequency converter efficiency | ≥96% |

| The output voltage | Output under rated conditions: three-phase 380 ~ 440V, error less than 5% |

|---|---|

| Output speed range | 4-pole motor 0 to 18000 rpm; 0 to 600 Hz |

| Motor control mode | Sinusoidal PWM modulation, full closed loop vector control |

|---|---|

| Speed control range | 1:1000 |

| Steady state speed accuracy | ≤0.05% rated synchronous speed |

| Starting torque | 200% rated torque at 0 Hz |

| Torque response | <10ms |

| Speed control accuracy | ±2% |

| Position control accuracy | ±1pulse |

| Overload capability | 200% rated current 20S |

| Digital input | 7-channel optocoupler isolated input, input mode NPN, PNP optional |

|---|---|

| Digital output | 2-way optocoupler isolated output |

| Analog input | 2 way: -10V~+10V, 0~10V, 0~20mA optional |

| Analog output | 1 way: 0~10V, 0~20mA optional |

| Relay output | 2 way: two sets of normally open normally closed contacts |

| Encoder input interface | 2 way: motor encoder 1 way; spindle encoder 1 way |

| Encoder output interface | 1 way: crossover output |

| Pulse input interface | 1 way: quadrature pulse / direction + pulse / CW + CCW |

| Bus interface | No |

| Speed control | range:0~12000RPM |

|---|---|

| Quasi-stop control | ±1pulse accuracy; 8 positions can be selected with terminals |

| Rigid tapping | Can interface with a variety of imported domestic systems, tapping error 2% |

| other functions | C-axis control, thread cutting, electronic gear, reaming, zero speed locking |

| Protective function | Overvoltage, undervoltage, current limiting, overcurrent, overload, electronic thermal relay, overheating, overvoltage stall, data protection, fast protection, input and output phase loss protection |

|---|

| Installation place | The altitude is less than 1000 meters, and the derating is more than 1000 meters. The derating is 1% for every 100 meters No condensation, icing, rain, snow, sputum, etc., solar radiation is less than 700W/m2, air pressure 70~106kPa |

|---|---|

| Temperature humidity | -10 ~ +50°C, derating can be used above 40 °C, the maximum temperature is 60 °C (no-load operation) 5% ~ 95%RH(No condensation) |

| vibration | when 9~200Hz,5.9m/s2(0.6g) |

| Storage temperature | -30 ~ +60℃ |

| Installation method | Wall-mounted, closet |

| Protection level | IP20 |

| Cooling method | Forced air cooling |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| SD500 Series Spindle Servo System Catalog V1.0 | Catalog | English | 2023-06-21 | 8.86MB | |

| SD500 Spindle Servo Drive Manual(Simplified) V1.4 | Manual | English | 2023-06-27 | 2.39MB | |

| SD500 Sevro Drive CM Spindle Motor Manual | Manual | English | 2023-06-06 | 56.1MB | |

| SD500 Series Spindle Servo Drive Manual V1.3 | Manual | English | 2020-09-25 | 1.48MB | |

| AC Drive PC Software V1.0 | Software | English | ZIP | 2024-02-20 | 46.5MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message