Rotary Cutting Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Rotary Cutting Machine Solution

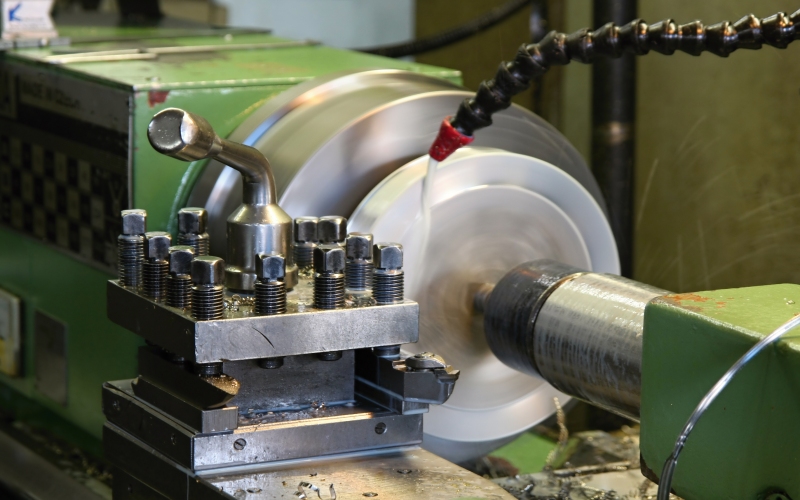

With the scarcity of forest resources and the increasing emphasis on the forest environment by the state, the efficient use of timber resources has become an important issue facing the entire woodworking equipment manufacturing industry. Rotary cutting machine is one of the main equipment for producing plywood.

In recent years, CNC rotary cutting and cutting machine has gradually become the mainstream model in the industry. The requirements for equipment in the industry continue to increase.

Features and Benefits

Through years of technical accumulation, CNC integrated machine of VEICHI provides system solutions, which greatly improves the processing quality and precision, production efficiency and ease of operation of the all-in-one machine.

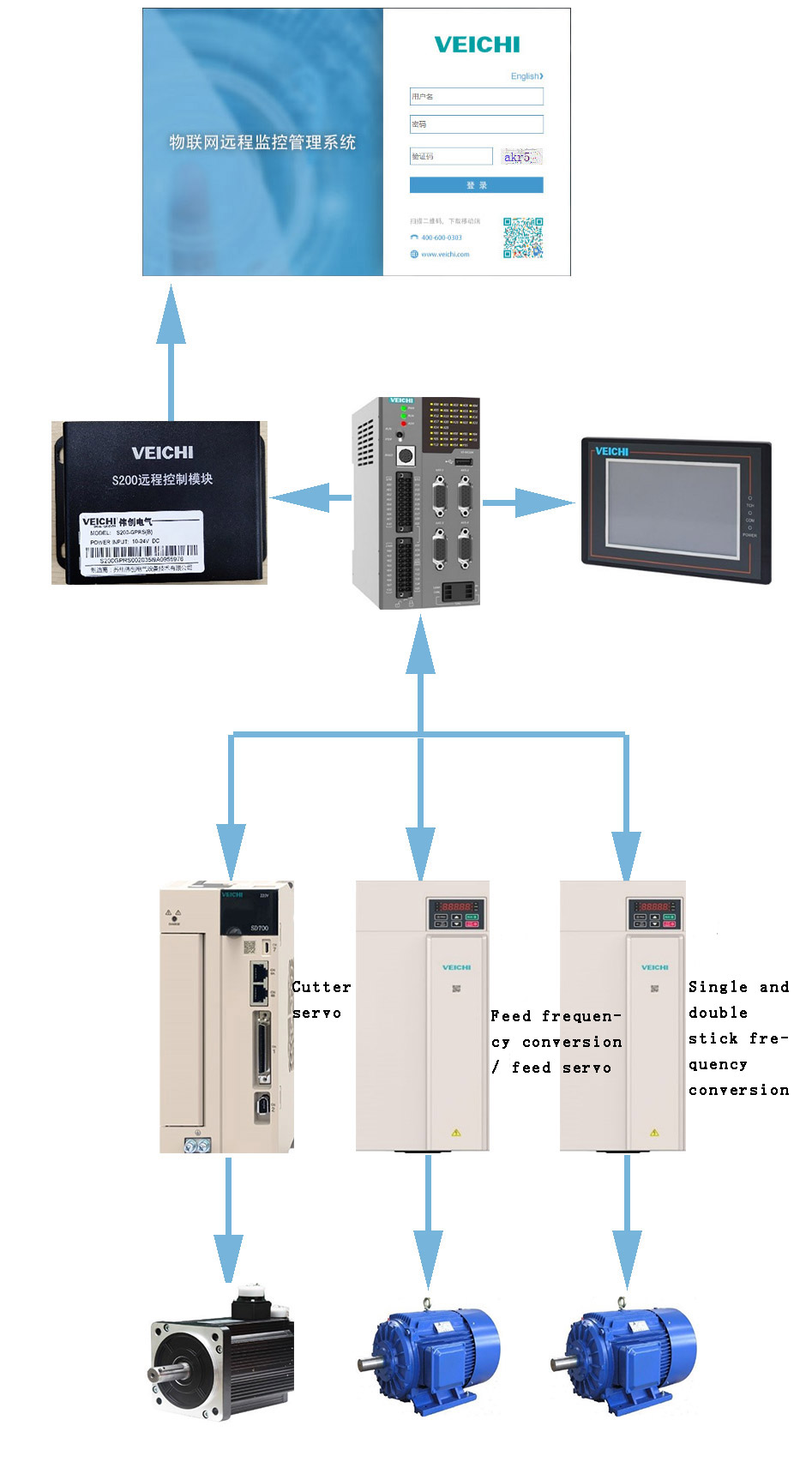

System introduction

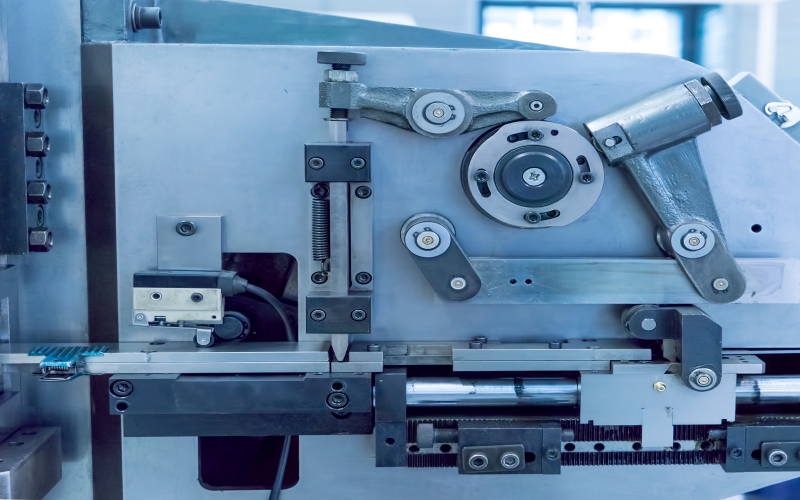

The VEICHI rotary cutter system uses the VEICHI high performance PLC (V5 motion controller) as the controller. The double roller is selected by VEICHI AC310 universal frequency inverter. The input tool uses the dedicated inverter of VEICHI AC310 rotary cutting machine or the servo drive of SD700 rotary cutting machine. The cutter uses the SD700 servo drive and is also equipped with the VEICHI IOT remote monitoring and management system.

The system adopts modular design and can be composed of single and double roller inverter + feed inverter + touch screen, or it can be composed of single and double roller inverter + feed servo + touch screen. It can also be composed of V5 motion controller + cutter servo + feed inverter (servo) + single and double roller inverter + touch screen. Among them, single and double roller inverters can choose other series of VEICHI inverters, and the IOT remote monitoring and management system can be used with the above systems. It can be split and combined according to the specific mechanical conditions without affecting the operation of the entire system.

System solutions

1. The product and hardware components applied to the system are shown in the figure below.

The product and hardware components applied to the system

2. Program implementation

The VEICHI high-performance motion controller V5-MC104 is used as the upper-level control to control the speed or position of the single-double-roller inverter/feed servo (inverter)/cutter servo through RS485 communication.

The system uploads the inverter or servo parameter information and fault information to the VEICHI IOT remote monitoring and management system through the V5 motion controller.

The touch screen transmits real-time data through the 422 communication and V5 motion controller.

System advantage

1. Rich modular system solutions

Operation controller solution: Single and double roll speed control, electronic cam cutting, remote control and other functions can be selected through modular combination.

Synchronous servo or frequency inverter can be selected as the power for feeding and cutting.

Special frequency converter solution: high integration and obvious cost advantages.

2. Simple operation and high processing accuracy

The special servo function of the rotary cutting feed is applied to the feed position curve to match the rotary cutting model to reduce the thickness error of the rotary cutting.

Single and double rolls can be arbitrarily changed according to demand to improve production efficiency.

The single and double rollers reduce the speed in advance, reduce the impact force of the machine and improve the service life of the machine.

3. Specialized electronic cam control for fixed length cutting, cutting speed and cutting speed of the cutting knife and the veneer, minimum cutting resistance, minimum wear of the rubber roller, high cutting precision and no complicated debugging.

4. The standard tailgate function does not require self-test, and the tailgate width is directly adjusted with an error of less than 1cm.

5. Remote parameter change and system status monitoring can be realized through the mobile phone without frequent on-site service.

6. It can be switched between two cutting widths, and the cutter rotates continuously without excessive width.

7. High-precision and low-inertia spindle servo motor further improves the cutting precision.

Summary

VEICHI rotary cutting machine system has the advantages of modularity, high efficiency, high precision and strong stability. The system solution can meet the needs of various customers. The system operation is very simple. After detailed communication with the on-site personnel, the system parameters are updated several times. The main purpose is to make the operation easy to understand. The thickness of the rotary cutting board is basically the same, the remaining wooden core is accurate in diameter, and there is basically no phenomenon that the tail plate is cut. The system has high compatibility, and the user can make minor adjustments according to the working conditions on the site. In most cases, the system can be stably operated without adjustment.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message