- Home > Product > Industry-specific Drive > Hydrogen Production > VHP800-E81 Series DC Power Supply Cabinet

VHP800-E81 Series DC Power Supply Cabinet

- Flexible Combination.

- Efficient Topology.

- On-grid Hydrogen Production Solution.

- Off-grid Hydrogen Production Solution.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

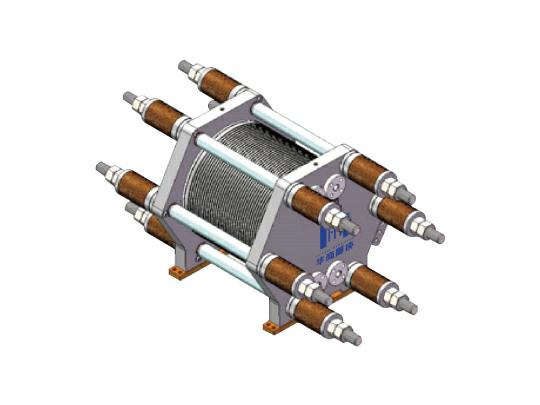

Product Introduction

High-power supply system with multiple DC power modules, featuring with separate regulation of voltage, current or power, ensuring high regulation accuracy and fast response. Modular design for free combination and expansion, providing high efficient, stable, safe and low harmonic DC power for large-capacity electrolyzer.

Product Feature

Flexible Combination

High Output Power: Parallel control structure with a max. output power of 10 MW.

Rapid Response: IGBT control, fast regulation response speed.

High Reliability: Excellent adaptability to grid fluctuations from new energy power generation, and harsh environment at -40℃ and 4000m.

High Grid-Friendliness: Harmonic content <3%, power factor ≥0.99, with functions as reactive power compensation and high/low voltage ride-through.

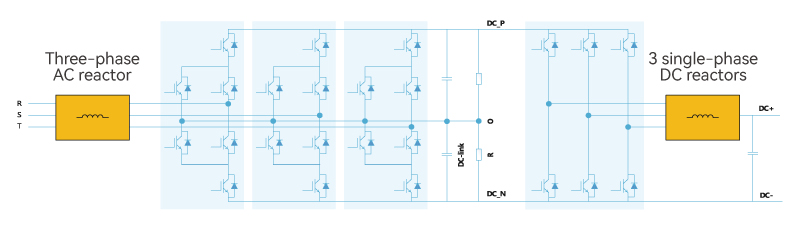

Efficient Topology

Power transformer + three-level rectifier + three-phase interleaved BUCK circuit for high efficiency;

DC voltage ripple ≤1%, overall efficiency ≥97% for smoother operation of electrolyzer and the whole system.

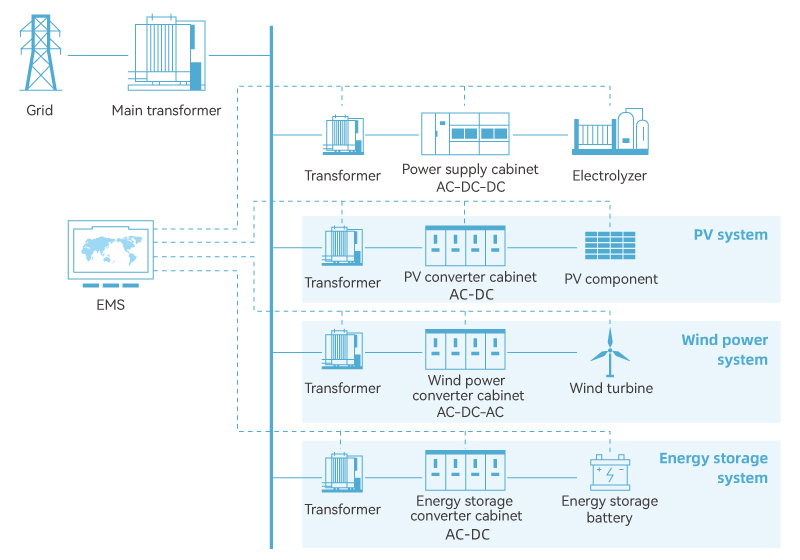

On-grid Hydrogen Production Solution

Diverse renewable energy sources secure energy reliability so as to enhance hydrogen production efficiency.

With an intelligent Energy Management System (EMS) for optimal control and coordination of wind, solar, energy storage, and hydrogen production equipment, a hybrid hydrogen production system is established to balance power supply and enhance hydrogen production efficiency.

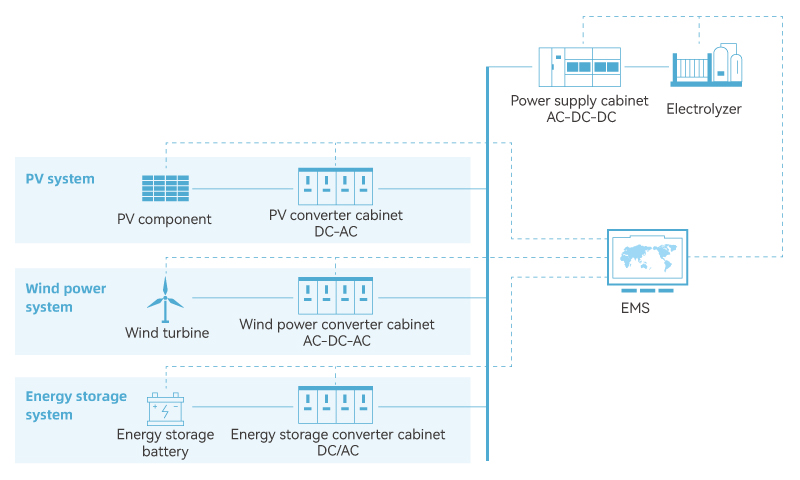

Off-grid Hydrogen Production Solution

Hydrogen is produced by supplying electricity directly from various renewable energy sources to a water electrolysis facility.

The EMS controls and coordinates all parts as a whole to fulfill power needs and enhance the hydrogen system's efficiency, speed, and reliability.

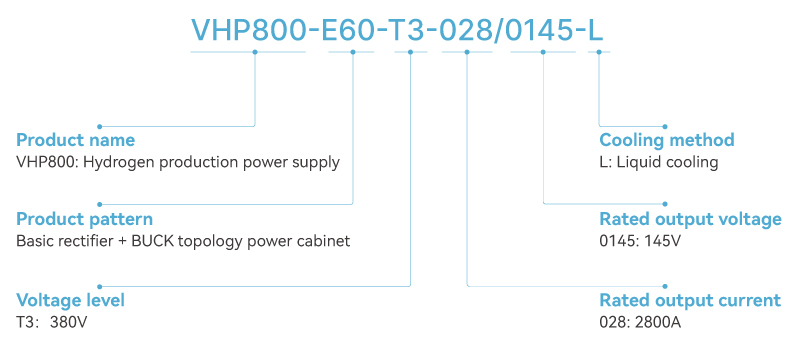

Naming Rules

VHP800 Series Hydrogen Production Power Supply Solution

Specifications

| Input | Input voltage range: 380V~1140V Rated operating frequency: 50Hz/60Hz Rated power factor: >0.99 Power factor range: -0.95 ahead~0.95 lag Grid frequency deviation: ±10% Grid voltage deviation: ±10% On-grid total harmonic distortion rate: <3% (at rated power) Connection method: 3-phase 3-line + PE |

|---|---|

| Output | Output voltage range: 0V~1500V Output current range: 0A~20000A Voltage ripple: ≤1% Current stabilizer accuracy: ±1% (steady state) Voltage stabilizer accuracy: ±1% (steady state) Load response time: <0.1s (0%~100% of load, operating status) |

| Control mode | Output control: Voltage control, current control, power control |

| Protection | Protection function: Short-circuit, over-current, over-voltage, under-voltage, phase loss, overheating, and overload, etc. |

| System | Inlet/outlet method: Upper/lower inlet, lower outlet Efficiency: ≥97% |

| Environment requirement |

Cooling method: Liquid cooling Operating temperature: -30℃~+60℃(>45℃ derating) Storage temperature: -40℃ ~+70℃ EME: Class A Relative humidity: 5%RH~ 95%RH (non-condensing) Enclosure IP: IP54 (Customization available) Max. altitude: 4000m (>3000m derating) |

| Communication | Interface: RS485, Ethernet, etc. Protocol: Modbus RTU, Modbus TCP, etc. |

| Noise | Noise (1m distance): ≤ 65dB |

| Display | HMI: Touch screen |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| Hydrogen Production Solution Catalog | Catalog | English | 2024-05-21 | 13.4MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message