- Home > Product > Industry-specific Drive > Hydrogen Production > VHP800-C60 Series IGBT Power Module

VHP800-C60 Series IGBT Power Module

- High-performance control strategy.

- High-performance control algorithms.

- Soft-start adjustment in the full load section.

- High power density.

- High-efficiency topology.

- Quick Response.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

Product Introduction

The IGBT power module adopts a two-stage scheme, with wide voltage and current range to deliver high efficiency, low interference and high precision. Power density is improved through water cooling so it is especially suitable for low-voltage and high-current occasions requiring adjustable output voltage and current, which provides safe, efficient and stable power supply for the green electricity hydrogen production.

Product Feature

High-performance control strategy

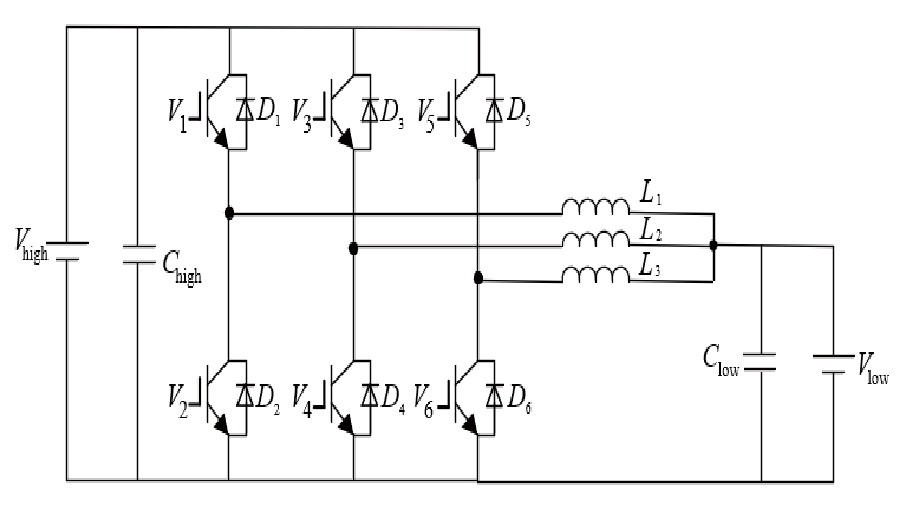

The main control system of the power supply adopts 6-pulse uncontrolled rectification + interleaved three-phase DC-DC structure for high control accuracy; And the digital controller adopts ARM architecture for fast computing and processing.

- High control accuracy

PID, digital filtering, constant voltage and current control and fault protection algorithms together realize high performance digital control.

- Quick processing

Precise ARM chip allows operation speed up to 550MHz.

- Multiple applications

AC/DC+DC/DC topology is adopted for flexible power supply. And PWM technology lowers grid current harmonic down to 3% to minimize its pollution.

High-performance control algorithms

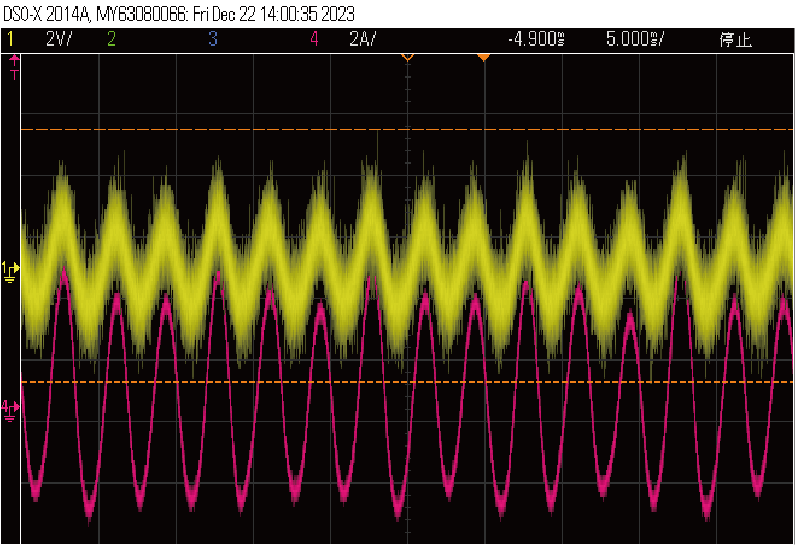

The voltage loop uses a feedback notch algorithm to filter out the industrial frequency ripple interference due to uncontrolled rectifier to reduce the output ripple.

The current loop adopts a unique bus voltage feedforward algorithm and PR control algorithm to provide high performance output ripple and control accuracy metrics as low as 1% (peak peak), the control accuracy can reach ±0.5%.

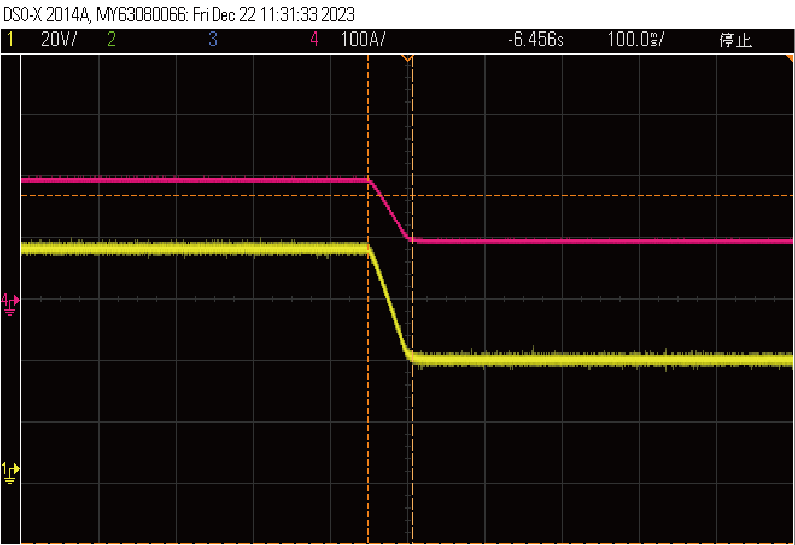

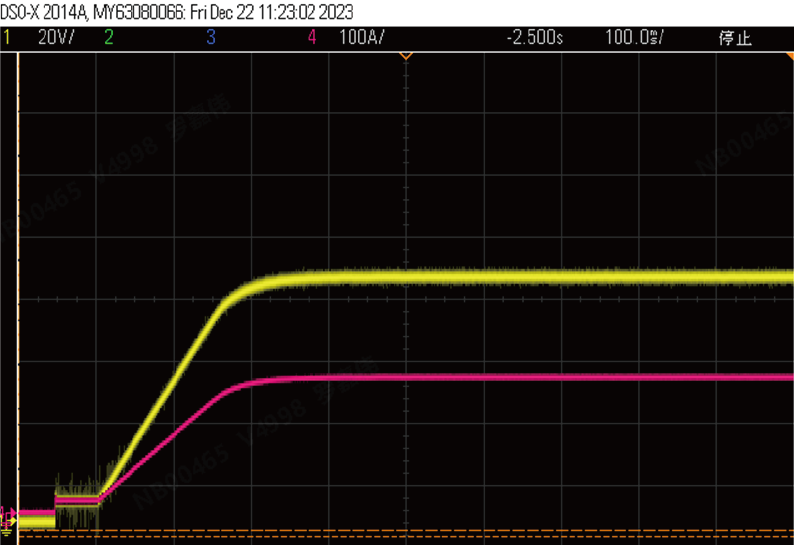

Soft-start adjustment in the full load section

The control loop is integrated with the voltage or current online soft-start setting function, so that rising or descending slope can freely adapt to start-up and given parameters of models with different power, providing more stable running performance.

In voltage loop operation mode, the current limit is switched from 200A to 100A (The software sets the slope to 2A/ms.).

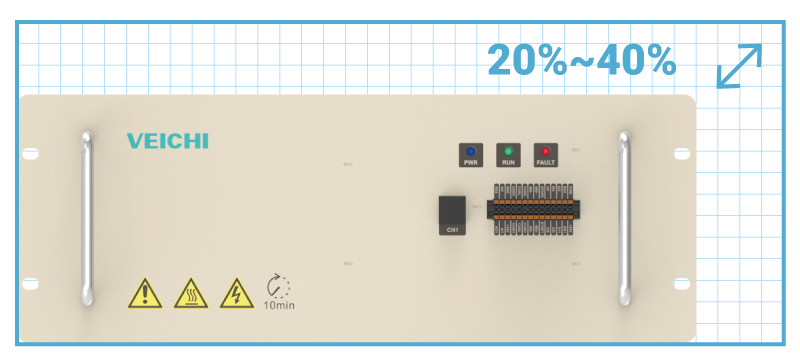

High power density

Integrated water cooling design delivers excellent heat dissipation performance in the small and delicate body which is 20%~40% smaller than market products.

High-efficiency topology

The three-phase interleaved parallel BUCK topology is used on the DC side for higher efficiency, smaller ripple current so that output current ripple is lower than 1%, and the overall efficiency is up to 94%-96%, which makes the electrolyzer and the whole system run more smoothly.

Quick Response

The voltage and current closed-loop control technology can still ensure the stability of hydrogen production from the electrolyzer in the case of frequent fluctuation or abrupt load change. The power adjustment response speed stays within 300ms, which can respond to photovoltaic and wind instantly with rapid power switching.

Waveform in yellow: Indicates the output voltage.Waveform in red: Indicates the output current.

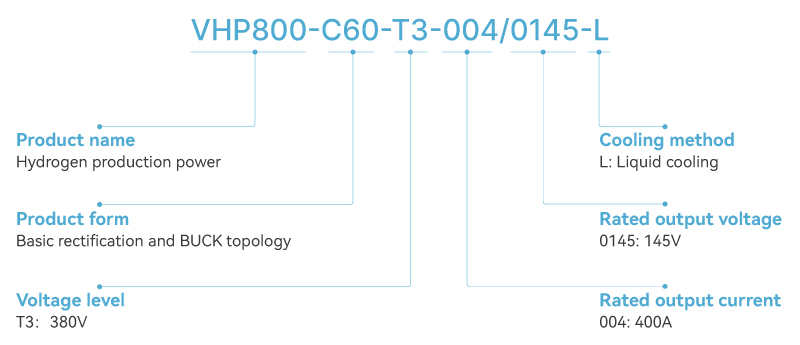

Naming Rules

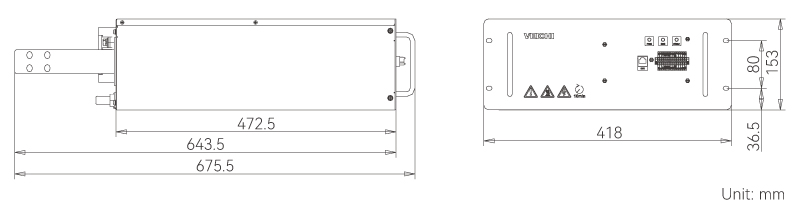

Installation Dimensions

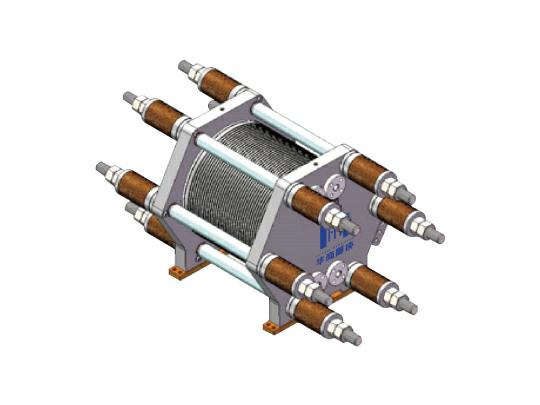

VHP800 Series Hydrogen Production Power Supply Solution

Specifications

| Input | Input voltage: 380VAC(-15%~ +20%) Input frequency: 50Hz/60Hz Rated capacity: 67kVA Rated current: 110A Efficiency: Rated ≥ 94% Power factor: ≥ 0.93 |

|---|---|

| Output | Output voltage: 0V~300V Output current: 0A~1000A Output power: 58kW Output voltage accuracy: ≤1% Output current accuracy: ≤1% Output ripple and noise: ≤1% |

| Communication | Control mode: Constant voltage, and constant current Analog signal: AI: 2 channels of 0V~10V, 2 channels of AO: 0V~10V Switching signal: DI:5 channels,DO:2 channels Interface: RS485 for Modbus and CAN communication |

| Protection | External protection: Short circuit, overcurrent, overvoltage, undervoltage, phase loss, overheating, overload, etc |

| Indicator | Status indicator: Power on indicator (blue)/Running indicator (green)/Fault indicator (red) |

| Environment | IP: IP30 Operating temperature: -30℃ ~+60℃ Storage temperature: -40℃ ~+70℃ Cooling method: Liquid cooling Water quality: Pure water, ethylene glycol 50% Humidity: 5%RH~95%RH, no condensation Highest elevation of the installation site: 4000m(>3000m Derating) |

| Electromagnetic compatibility and Safety |

Electromagnetic Compatibility(Conduction and radiation): IEC 61800-3 C3 Security protection requirements: Safety requirements: Designed according to CE ROHS standard: Meet the requirements of ROHS standard Lightning protection: indoor |

| Noise | Noise (distance of 1m): ≤ 65dB |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| Hydrogen Production Solution Catalog | Catalog | English | 2024-05-21 | 13.4MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message