- Home > Product > Industry-specific Drive > Hydrogen Production > VHP800-E60 Series IGBT Power Module

VHP800-E60 Series IGBT Power Module

- Master-Slave Control.

- Comprehensive Protection.

- Redundancy Switch Control.

- High Power Density.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

Product Introduction

The power supply system integrates up to 7 IGBT modules in a modular format, allowing for flexible combination, and independently controls voltage, current, or power with high accuracy and speed. The output parameters can be smoothly varied from zero to maximum without steps. Encased in a robust frame, the cabinet can handle heavy loads and seismic activity in challenging conditions.

Product Feature

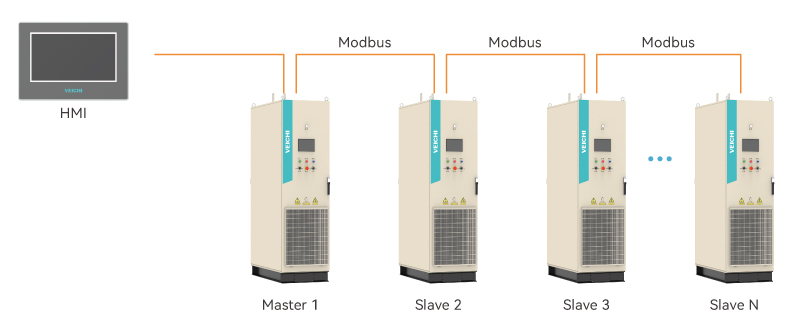

Master-Slave Control

Adopt master/slave processors for controlling system functions. The software specifies a cabinet as the master or slave, and if the master module is damaged, the next slave cabinet can be switched to the master.

Comprehensive Protection

Black Box: Save data before and after failures in a specified time

Single Module Protection: Offer protections for short circuit, overcurrent, overvoltage, undervoltage, phase loss, overheat, overload, etc.

Electrolyzer Protection: Adapt to the electrolyzer characteristics and switch the protection strategy flexibly

Redundancy Switch Control

Multiple Redundancy Design: Each module operates separately, so if there's a problem with one, it can be quickly resolved to maintain overall reliable performance.

Layered Protection: Ensures maximum availability of the equipment.

High Power Density

Compact drawer design greatly saves the cabinet space. 20%~30% smaller than market product.

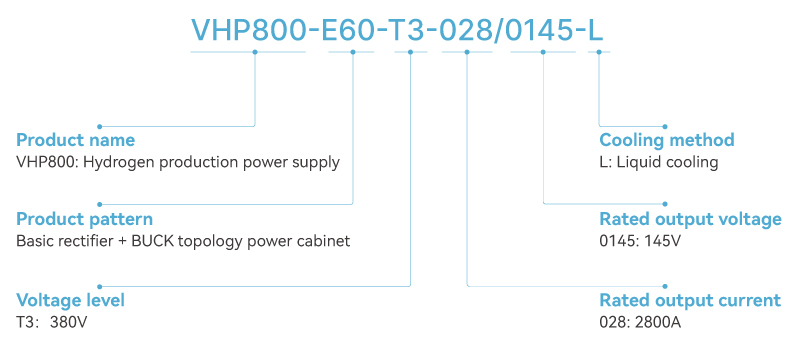

Naming Rules

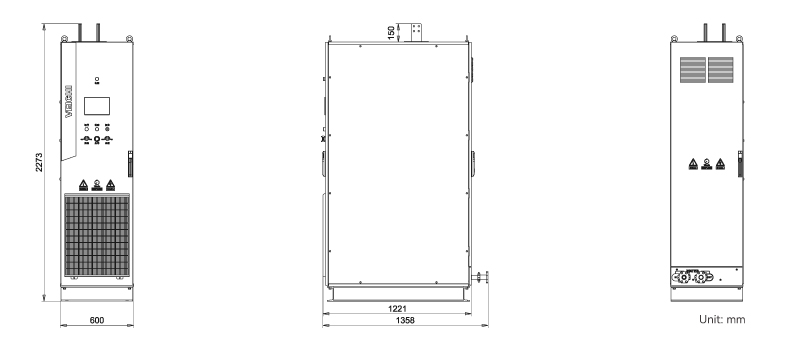

Installation Dimensions

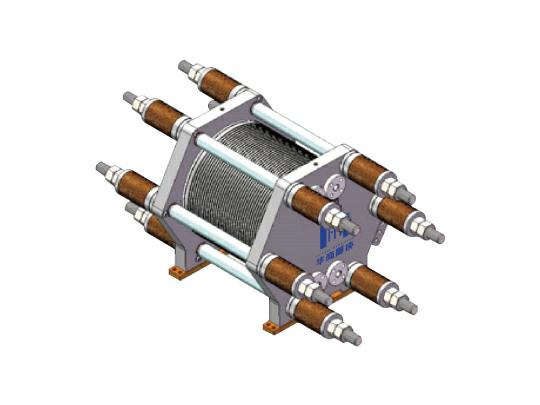

VHP800 Series Hydrogen Production Power Supply Solution

Specifications

| Input | Input voltage: 380VAC(-15%~ +15%) Input frequency: 50Hz/60Hz Rated capacity: N (N≤7): number of cabinets in parallel Rated current: N x110A Efficiency: Rated ≥ 94% Power factor: ≥ 0.93 |

|---|---|

| Output | Output voltage: 0V~300V Output current: 0A~N×1000A (N: number of cabinets in parallel) Output power: N×58kW (N: number of cabinets in parallel) Output voltage accuracy: ≤1% Output current accuracy: ≤1% Output ripple and noise: ≤1% |

| Communication | Control mode: Constant voltage, and constant current Analog signal: Host PC given Switching signal: DI:5 channels,DO:2 channels Interface: External RS485, Internal CAN |

| Protection | External protection: Short circuit, overcurrent, overvoltage, undervoltage, phase loss, overheating, overload, etc |

| Indicator | Status indicator: Power-on (blue) / run (green) / fault (red) HMI: Output status / Fault alarm |

| Environment | Operating temperature: -30℃~+60℃ (40℃~60℃ derating) Storage temperature: -40℃ ~+70℃ Cooling method: Liquid cooling Humidity: 5%RH~95%RH, no condensation Highest elevation of the installation site: 4000m(>3000m Derating) |

| Electromagnetic compatibility and Safety |

Electromagnetic Compatibility(Conduction and radiation): IEC 61800-3 C3 Security protection requirements: Safety requirements: Designed according to CE ROHS standard: Meet the requirements of ROHS standard Lightning protection: indoor |

| Noise | Noise (distance of 1m): ≤ 65dB |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| Hydrogen Production Solution Catalog | Catalog | English | 2024-05-21 | 13.4MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message