- Home > Product > Industry-specific Drive > Hydrogen Production > HX1 Series Alkaline Electrolyzer

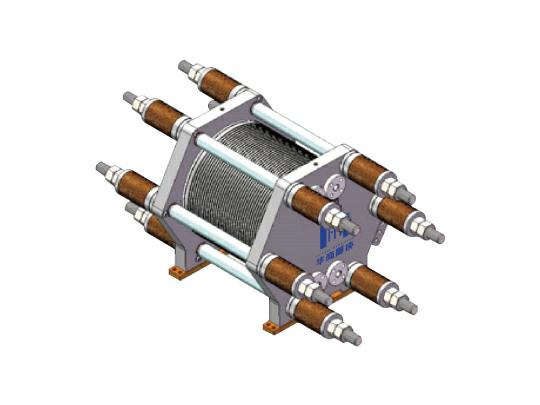

HX1 Series Alkaline Electrolyzer

- Low Cost.

- Long Life.

- Fast Start/Stop.

- Light Weight.

- Stable & Safe Operation.

- Wide Power Range.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

Product Introduction

CM Xiageng's next-generation products features innovative materials, structures, and production techniques. Starting with fundamental material chemistry research, the company innovates core components such as electrodes, diaphragms, and the structure like diffusion layers for hydrogen production via alkaline water electrolysis. Addressing the industrial challenges of gas-liquid separation and power system compatibility, it significantly improves equipment performance and stability. This innovative approach results in this advanced hydrogen production equipment characterized by high current density, low energy consumption, and quick cold-start capability, providing performance on par with PEM systems but at a more competitive cost compared to market peers.

Product Feature

Low Cost

Industry-leading low power consumption design to save energy by 5%~15%, annual power of 2 million kWh~4 million kWh, total cost of 400,000 yuan~800,000 yuan.

Long Life

Overhaul cycle from 5 to 10 years, service life up to 20 years.

Fast Start/Stop

Cold start time of 15 minutes, providing customers with additional work hours.

Light Weight

Lightweight, miniaturized design with 36% weight reduction.

Stable & Safe Operation

PPS complex film with better airtightness and stability, ensuring safer operation.

Wide Power Range

Fast response to power fluctuations for better adaptation to renewable power inputs.

Industrial Applications for HX1 Series Alkaline Electrolyzer

Applications:metallurgical industry, hydrogenation, new energy off-grid hydrogen production, ammonia industry, offshore hydrogen production and green ammonia, green methanol energy.

VHP800 Series Hydrogen Production Power Supply Solution

Specifications

| Capacity(Nm³/h) | HX1-2: 2 HX1-5:5 HX1-10: 10 HX1-30: 30 HX1-50: 50 HX1-80: 80 HX1-100: 100 HX1-150: 150 HX1-200: 200 HX1-250: 250 HX1-300: 300 HX1-400: 400 HX1-500: 500 HX1-800: 800 HX1-1000: 1000 HX1-1500: 1500 |

|---|---|

| Speed rate | Hydrogen production: 2Nm³/h~1500Nm³/h |

| Range | Load: 30%~120% Power range: 10%-180% |

| Protection | Electrolyte diaphragm: PPS, complex film |

| Operating environment | Pressure: ≥1.6MPa Temperature: 90℃~95 ℃ |

| Power consumption | DC: 4.0kWh/Nm³~4.4kWh/Nm³ |

| Maintenance | Overhaul cycle: 5 years~10 years |

| Service life | Product life: 20 years |

| Weight | Product weight : < 30 t (1000 Nm3/h) |

| Current density | Low energy consumption: 1000~5000A/㎡ Low cost stack: 5000~10000A/㎡ |

| Operating voltage | Low energy consumption: 1.68V~1.85V Low cost stack: 1.85V~1.95V |

| Average consumption | Low energy consumption: 4.0kWh/Nm³~4.2kWh/Nm³ Low cost stack: 4.2kWh/Nm³~4.4kWh/Nm³ |

| Max. output | Low energy consumption: 1300Nm³/h Low cost stack: 1250Nm³/h |

| Design parameters (customizable current density 10000A/m2-12000A/m2, Operating voltage: 1.85-1.95V) |

Current density: 4000A/㎡ 6000A/㎡ 8000A/㎡ 10000A/㎡ Chamber voltage: 1.60-1.65V 1.71-1.75V 1.75-1.80V 1.85-1.88V Average consumption: 3.8-3.9kWh/m³ 4.1-4.2kWh/m³ 4.2-4.3kWh/m³ 4.4-4.5kWh/m³ |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| Hydrogen Production Solution Catalog | Catalog | English | 2024-05-21 | 13.4MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message