Four-gun Automatic Welding Machine for Angle Iron Flange Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Four-gun Automatic Welding Machine for Angle Iron Flange Solution

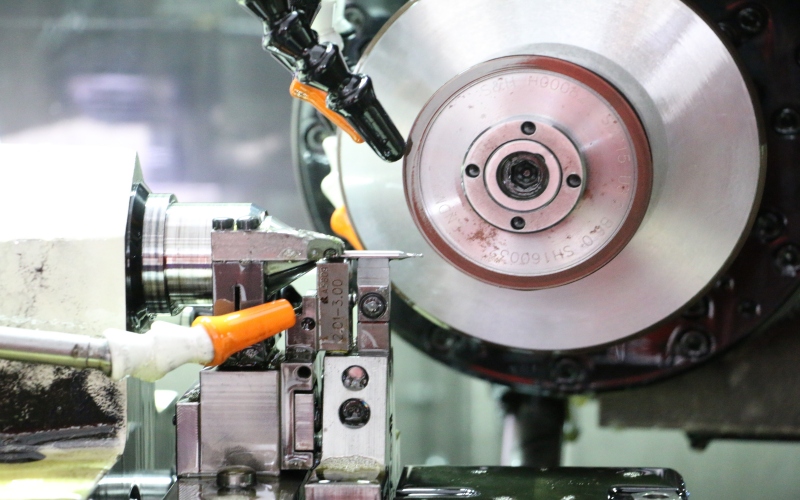

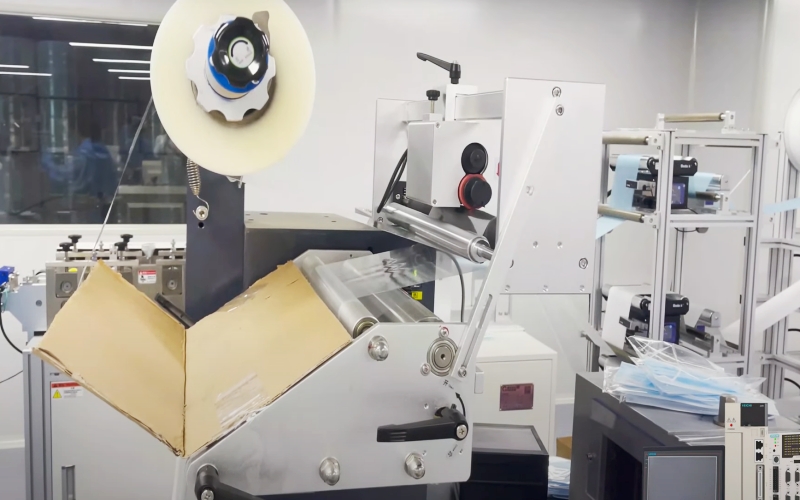

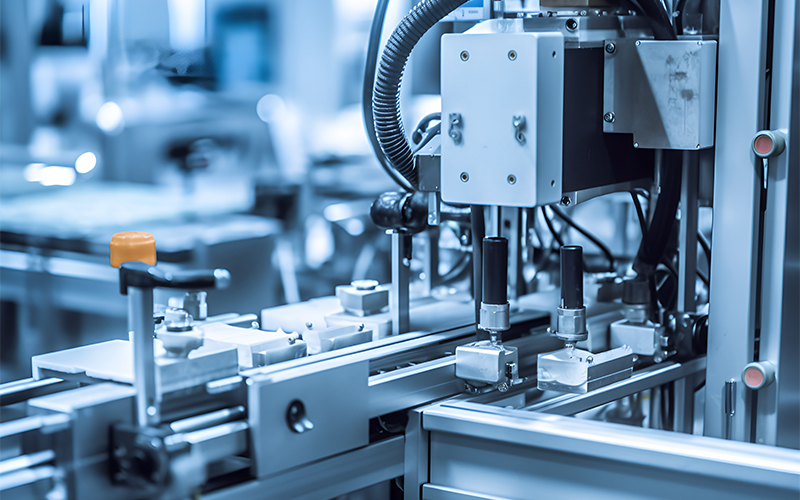

The angle iron flange four-gun automatic welding machine can realize the automatic cutting function, saving time and effort. Using four-gun welding technology, four corners are synchronized and automatically positioned to ensure efficiency and accuracy. Push-button one-key start, built-in welding machine, can weld four corners at the same time, occupying a small area. The control system is reliable and stable. It is widely used in metal sheet processing, forming machine tool industry, and other mechanical equipment manufacturing fields. It is used in the angle welding of different specifications of angle iron flanges for cooling air ducts, subway ventilation, building ventilation, HVAC, and purification functions.

Features and Benefits

Introduction

The angle iron flange four-gun automatic welding machine can realize the automatic cutting function, saving time and effort. Using four-gun welding technology, four corners are synchronized and automatically positioned to ensure efficiency and accuracy.

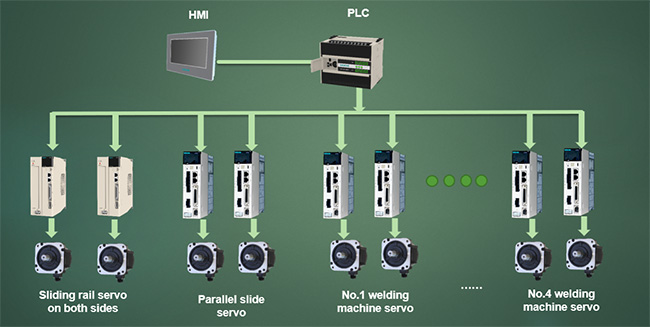

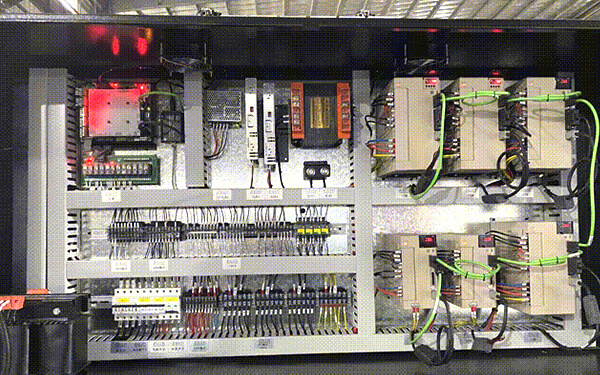

System topology

Program highlights

1. The man-machine interface is centrally controlled to realize recipe parameter setting, production data monitoring, output counting, and the operation is more intelligent and simple.

2. All parameters are displayed in real-time by the man-machine interface, and the left and right positions of the welding machine, actual stroke, speed, positioning reference position, etc. can be preset.

3. The Servo System has accurate positioning, fast response speed, and good anti-interference performance, which can realize accurate and synchronous welding of materials by four welding machines.

Process principle

The angle iron flange four-gun automatic welding machine is mainly composed of the following parts:

Machine mechanism: Carrying a welding platform and four welding torch mechanisms installed on the welding platform, on which the entire welding work is performed.

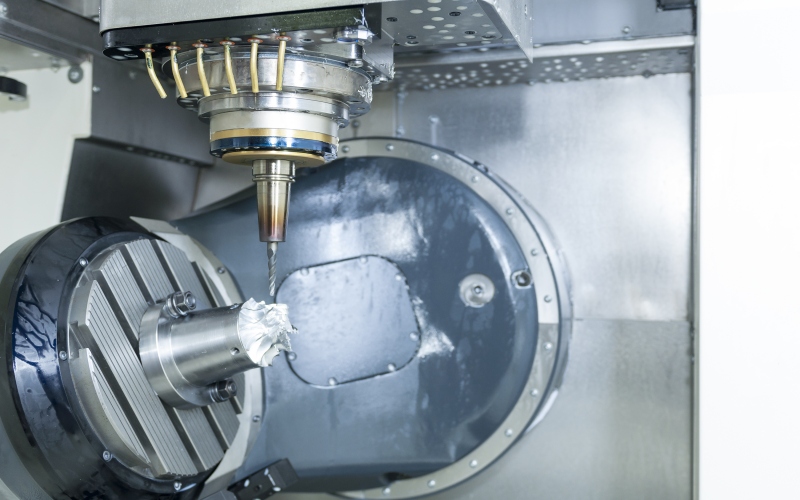

Welding platform: Two slide rails are arranged on both sides of the welding platform, and the gears driven by two servo motors mesh with the racks provided with slide rails on both sides. In addition, there are two parallel slide rails across the welding platform. Four slide tables, two fixed slide tables, and two mobile slide tables are installed on the parallel slide rails, which are linked with the screw through the servo motor. The processing parts of different sizes move quickly.

Welding torch mechanism: each sliding table is equipped with a welding torch mechanism. The welding torch mechanism has a lifting adjustment part and a horizontal adjustment part. The welding action is realized by a servo motor and a screw platform. The welding torch mechanism on the four sliding tables is moved to the upper position. After the device is driven by the command, it moves incoordination, and there is no need to move in the middle of welding, and the walking distance is short.

Technical index

The normal operating speed of the welding gun can reach 500mm/s and the four corners can be welded at the same time, and the weld can be completed in 9 seconds.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message