Bending Hoop Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Bending Hoop Machine Solution

A fully automatic CNC bending machine is mainly used in the processing of materials in the construction industry, and steel bars of various shapes are the most used component on the building construction site. For a long time, it has been made manually by construction workers, which is not only inefficient but also inaccurate. It severely restricted the progress of the construction period and the overall construction quality of the building. With the widespread application of motion control systems, the design of CNC hoop bending machines is finalized, and a large number of CNC hoop bending machines are used in the processing of steel materials in the construction industry. With this equipment, 7.5 tons of steel bars can be processed per shift without occupying a large area. Only one worker is required to work, which is nearly 40 times more efficient than the original manual method.

Features and Benefits

Industry Introduction

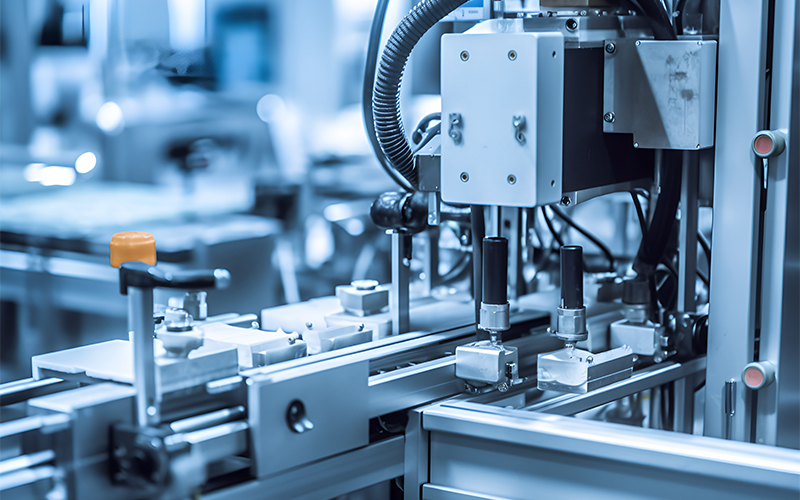

A fully automatic CNC bending machine is mainly used in the processing of materials in the construction industry, and steel bars of various shapes are the most used component on the building construction site. With the widespread application of motion control systems, the design of CNC hoop bending machines is finalized, and a large number of CNC hoop bending machines are used in the processing of steel materials in the construction industry.

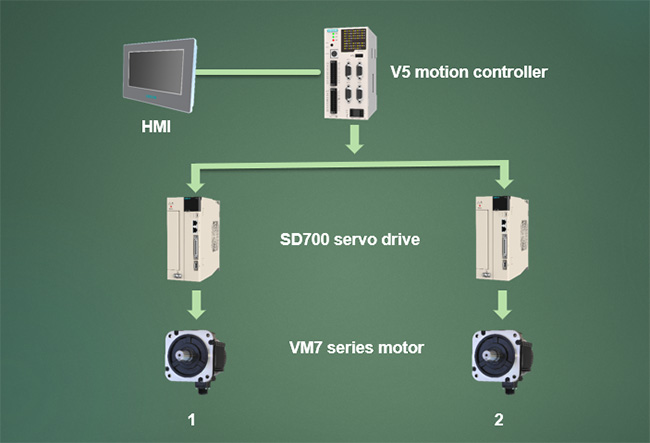

System topology

Program highlights

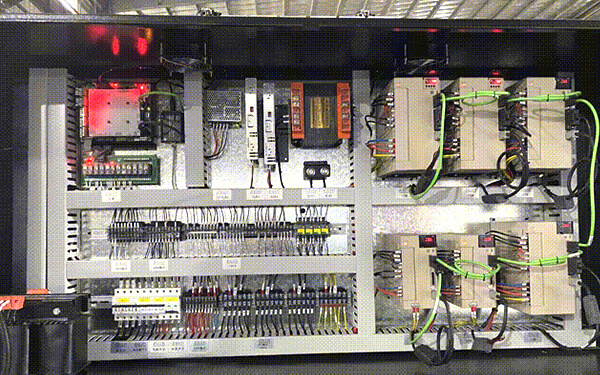

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. The man-machine interface is centrally controlled to realize recipe parameter setting, production data monitoring, output counting, and the operation is more intelligent and simple.

The connection between the V5 controller and the servo drive adopts high-speed differential signals, which have high stability and are not susceptible to interference. The maximum pulse speed of the differential pulse port is 3MHz, which can achieve extremely high control accuracy. The production efficiency of a single machine can reach 8 to 10 times that of manual and semi-automatic hoop bending machines, which is nearly 40 times more efficient than the original manual method.

Process principle

The hoop bending machine is mainly composed of a traction mechanism, a bending mechanism, and a cutting mechanism.

Traction mechanism: It is composed of two sets of horizontal and vertical automatically adjustable straightening wheels, combined with four traction wheels, driven by a servo motor, and adopts a fully closed loop non-standard to ensure the accuracy of steel delivery.

Bending and shearing mechanism: Driven by a servo motor, the bending arm can rotate and retract at high speed, and the shearing mechanism completes the cutting action at high speed.

The process flow of the hoop bending machine includes: coiling→straightening→bending→shearing.

Technical index

The feeding accuracy can reach ±1mm.

The feeding speed can reach 100 m/min, and the bending accuracy can reach ±1 degree.

The bending speed can reach 1500 degrees/sec.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message