Glass Edging Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Glass Edging Machine Solution

With the rapid development of urban construction and the development of deep processing of glass products, such as functionalization, practicality, and decoration, the market demand for glass edging machines, as necessary professional equipment for glass deep processing, is increasing. The glass four-sided edging machine is professional processing equipment for the chamfering of the rectangular original glass. With the rapid development and addition of automation and bus technology, the glass edging machine system automatically recognizes the glass size without manual input and adjustment of the glass size. Complete continuous glass edging tasks accurately and smoothly.

Features and Benefits

Introduction

The pre-processing of tempted glass mainly includes glass cutting, glass edging, glass drilling, glass washing, and so on. Glass edging is a very important process in glass deep processing, it performs secondary processing on the four edges and corners of the cut glass by manual or mechanical methods.

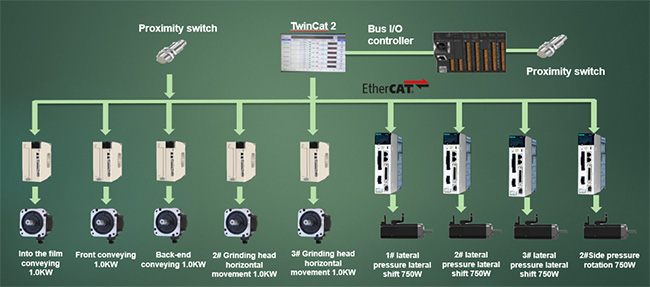

System topology

Program highlights

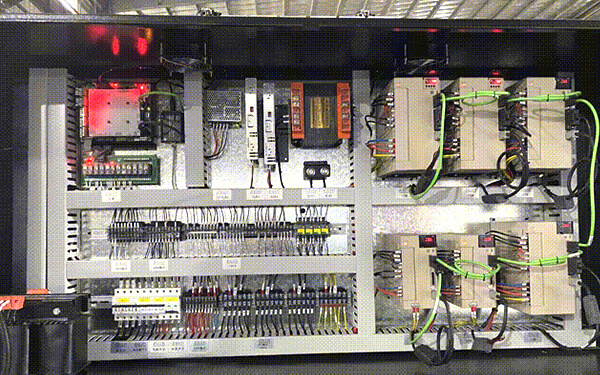

1. Using the EtherCat bus control scheme, the PLC does not need to send pulses to control the servo, which simplifies the wiring and enhances the transparency of the system and the anti-interference ability of the system.

2. Using VEICHI EtherCat bus servo control, it is convenient to realize the actions of changing workpiece parameters and replacing workpieces, which increases the flexibility of the equipment and makes it suitable for processing a variety of different styles of glass.

3. The servo bottom layer has the pulse position capture function (probe function), which does not require the PLC to participate in the capture of the position signal, which can make the PLC focus on logic control, simplify the programming of the PLC program, shorten the debugging time, and improve the competitiveness of the machine.

4. Excellent underlying algorithm, stable torque output, 3 times the overload capacity to meet the product production process.

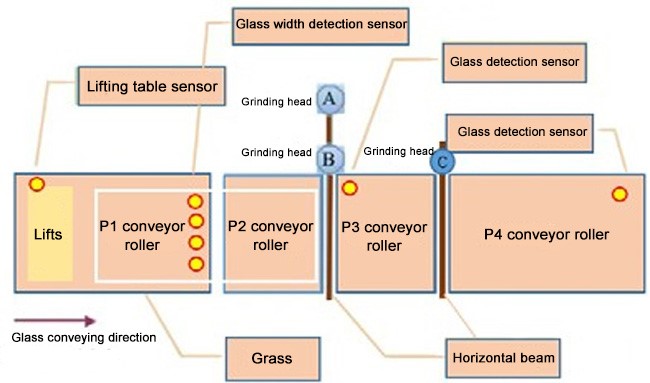

Process principle

The glass four-side grind is divided into three parts: the entry table, the edging rack, and the exit table. The film-in table and the film-out table are matched with the edging rack to grind the glass. The edging frame has 3 groups of grinding heads. There are two grinding wheels for each group of grinding heads. It can be combined with a cutting line, automatic loading and unloading table, washing machine, and other equipment to form a fully automatic glass processing unit. The glass four-side grinding machine is mainly composed of conveying rollers, sensors and three groups of grinding heads.

Technical index

Automatically recognize glass size.

Six-axis linkage.

Different specifications and thickness of glass can be loaded continuously.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message