- Home > Product > Industry-specific Drive > Construction Machinery > QT Series Integrated Tower Crane Drive

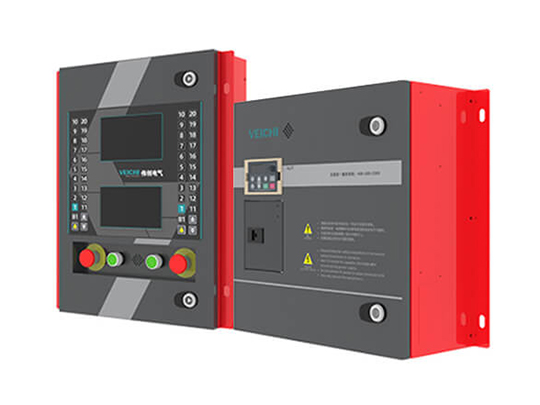

QT Series Integrated Tower Crane Drive

- Enable the tower crane work more safely, reliably and efficiently.

- Reduce machine wear and prolong the service life of tower crane.

- High performance tower crane driver with rich functions and best price.

- Easy in operation and maintenance.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

QT Series Integrated Tower Crane Drive Overview

QT tower crane integrated drive is a mid-to-high-end model designed for intelligent modularization and lightweight design for tower crane electronic control requirements. It integrates the frequency conversion control unit, logic control unit, and black box monitoring unit (extension) of the lifting, slewing, and luffing mechanism. It can improve the safety and stability of the tower crane and solve the problems of equipment maintenance difficulties. Provide customers with a high-performance, complete tower crane system solution.

Modular Design, Integrated with Five Core Units

VEICHI QT series tower crane control system has specially developed with modular design: the lifting, slewing and luffing control module run independently without interference. Besides, it has been integrated with IOT control unit.

Lifting control unit

1. It adopts open loop vector control, closed loop vector control and V/F control mode.

2. It is capable of running for a long time, braking at zero speed and running smoothly without shaking. By using QT series, it extends the service life of tower crane's components such as transmission mechanism, steel wire rope and more parts. Meanwhile, it effectively improves the safety of tower crane.

3. Strong adaptability to power grid: at low voltage, it can maintain constant output torque.

4. Improved working efficiency: automatically start high speed status when the crane is in light load.

5. Developed with dedicated brake logic timing control and dual redundant brake control, it is more safe and reliable.

6. In closed loop mode, it has stall protection function, zero servo hovering function and anti-slip hook subsidiary protection, so it makes tower crane work with improved reliability.

Slewing control unit

1. QT02 tower crane inverter adopts flexible torque control that it features powerful jog, fast response, steady running without rebound.

2. It can adapt to various kinds of motor control such as vortex motor rigid connection, the fluid coupling soft connection and torque motor rigid connection.

3. The built-in vortex controller adopts PWM pulse width modulation that it can adjust the output voltage in real time according to the running frequency. Comparing with conventional eddy current voltage regulator module, it is of more outstanding performance.

4. It makes the gear convert stably and fluently without pause phenomenon.

Luffing unit

Developed with anti-swing function, it makes easy in hooking.

IOT remote control unit

1. Through remote monitoring module, it can achieve online monitoring and remote fault diagnosis.

2. Remotely monitor the tower crane to check whether it’s overweight, illegally operated and more in order to prevent accidents from happening.

Complete Protection Functions

It includes overweight, super torque, spacing limit, over current, overvoltage, under voltage, loss phase, short circuit protection and more protection functions.

User-friendly and Water-proof Design

QT series have been designed with clear LED indication and silkscreen in all the main order, spacing limit, emergency stop, and safe feedback signals and etc. It is very easy for engineers to operate and maintain. Besides, it is of outdoor waterproof design with IP25 protection class.

Industrial Applications for QT Integrated Tower Crane Drive

Applications:Tower crane.

Specifications

| Types: Rise | Adapted motor power: 22/24KW; Rated voltage: Three phase; Rated current: 60 |

|---|---|

| Types: Turn around | Adapted motor power: 3.7KW*2/5.5KW; Rated voltage: 380V; Rated current: 32 |

| Types: Luffing | Adapted motor power: 4KW; Rated current: 10 |

| Types: Rise | Adapted motor power: 30KW; Rated current: 75 |

|---|---|

| Types: Turn around | Adapted motor power: 3.7KW*2/5.5KW*2; Rated current: 32 |

| Types: Luffing | Adapted motor power: 4KW; Rated current: 10 |

| Types: Rise | Adapted motor power: 37KW; Rated current: 90 |

|---|---|

| Types: Turn around | Adapted motor power: 5.5KW*2; Rated current: 32 |

| Types: Luffing | Adapted motor power: 5.5KW; Rated current: 12 |

| Types: Rise | Adapted motor power: 45KW; Rated voltage: Three phase; Rated current: 110 |

|---|---|

| Types: Turn around | Adapted motor power: 5.5KW*2; Rated voltage: 380V; Rated current: 36 |

| Types: Luffing | Adapted motor power: 5.5KW; Rated current: 15 |

| Types: Rise | Adapted motor power: 55KW/60KW; Rated current: 150 |

|---|---|

| Types: Turn around | Adapted motor power: 5.5KW*3; Rated current: 45 |

| Types: Luffing | Adapted motor power: 7.5KW; Rated current: 22 |

| Types: Rise | Adapted motor power: 75KW; Rated current: 180 |

|---|---|

| Types: Turn around | Adapted motor power: 5.5KW*3; Rated current: 45 |

| Types: Luffing | Adapted motor power: 7.5KW; Rated current: 22 |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| Crane Solution Catalog | Catalog | English | 2024-04-10 | 4.64MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message