- Home > Product > Industry-specific Drive > Construction Machinery > AC70T Hoist Special Drive

AC70T Hoist Special Drive

- Automatic speed increment when light load or empty hook, matching optimal operating speed

- Zero-speed torque retention prevents the brake from slipping due to long mechanical delays

- Synchronous control function ensures that two hoisting mechanisms are synchronized to ensure safety

- Anti-collision function to prevent collision

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

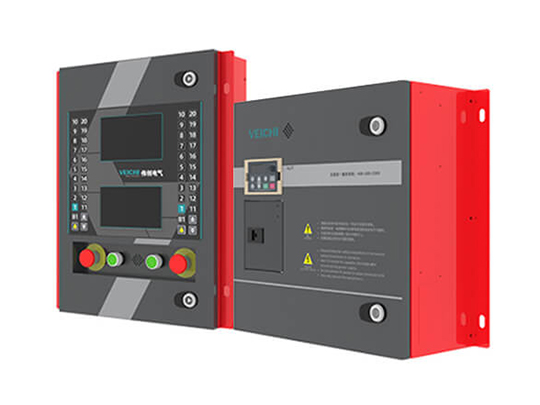

AC70T Hoist Special Drive Overview

AC70T hoisting special frequency drive is specially designed for the application of the industry. It has perfect functions, good protection effect (resistance to salt spray corrosion), and excellent performance, ensuring the safety, reliability and efficiency of hoisting machinery. It is suitable for the drive of lifting, pitching, trolley, slewing, luffing, etc. in industries such as port machinery, ship machinery, construction machinery, mining machinery, cranes, gantry cranes, electric hoists, cranes and hoists.

Functions

1. Light load and high speed.

2. Zero-speed torque maintenance.

3. Synchronous control of multiple motors.

4. Anti-collision function.

Features

Stable operation at low frequency and large torque

0.5Hz/150% rated torque output smoothly, to ensure that the lifting equipment runs smoothly during starting, rising and falling.

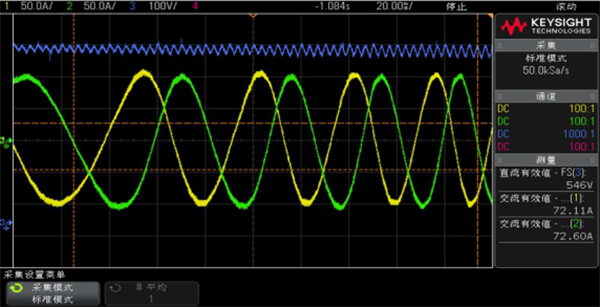

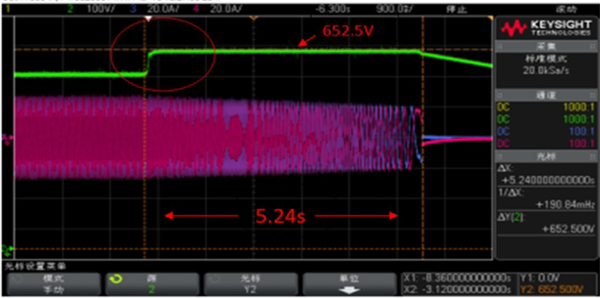

Excellent current suppression and bus voltage suppression

The current suppression function can avoid frequent over-current alarms of the inverter. When the current exceeds the current protection point, the overcurrent suppression function can continuously limit the current within the current protection point, thereby protecting the safety of the equipment and avoiding overcurrent alarms caused by sudden load or interference.

The overvoltage suppression function can avoid the overvoltage alarm of the inverter during acceleration and deceleration. When the inverter bus voltage reaches or exceeds the protection point during acceleration and deceleration, the overvoltage suppression function can automatically adjust the operating frequency to suppress the rise of the bus voltage, thereby protecting the safety of the equipment. Avoid the overvoltage alarm caused by the increase of the bus voltage of the inverter.

Wide speed range

The output frequency range is 0-320Hz, which meets the requirements of light load notification, heavy load and low speed of lifting equipment, and improves the efficiency of the equipment.

Super overload capacity

150% rated current for 1 minute, 180% rated current for 10 seconds, and 200% rated current for 0.5 seconds.

Stall protection function (closed loop mode)

When it is detected that the actual speed exceeds 115% of the rated speed during operation, the inverter quickly sends out a brake signal to realize emergency braking.

Dedicated brake control logic

Control the brake (brake) of the lifting equipment to open and close in a reasonable time sequence to ensure the safety and reliability of the system.

Wide voltage input range

Automatic voltage stabilization: to ensure that when the grid voltage drops, the output can still meet the torque output requirements of the lifting equipment, and the allowable input voltage fluctuation range is ± 20%.

Industrial Applications for AC70T Hoist Special Drive

Applications:Port machinery, ship machinery, construction machinery, mining machinery, cranes, gantry cranes, electric hoists, cranes and hoists, etc.

Specifications

| Power range | 750 W-200,000 W |

|---|

| Voltage frequency | Three-phase 380V 50/60Hz |

|---|---|

| Allowable fluctuation | Voltage imbalance rate: <3%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements/span> |

| Closing impulse current | ≥0.94 (with DC reactor) |

| Inverter efficiency | ≥96% |

| The output voltage | Output under rated conditions: 3-phase, 0~input voltage, error less than 5% |

|---|---|

| Output frequency range | 0~320Hz |

| Output frequency accuracy | ±5% of maximum frequency value |

| Overload capacity | 150% rated current for 1 minute, 180% rated current for 10 seconds, 200% rated current for 0.5 seconds |

| Carrier frequency | 0.6~15.0kHz |

|---|---|

| Speed control range | Vector control without PG, rated load 1:100; vector control with PG, rated load 1:1000 |

| Steady-state speed accuracy | Vector control without PG: ≤1% rated synchronous speed |

| Starting torque | Magnetic flux vector control without PG: 150% rated torque at 0.5Hz |

| Frequency accuracy | Digital setting: maximum frequency×±0.01%; analog setting: maximum frequency×±0.2% |

| Frequency resolution | Digital setting: 0.01Hz; Analog setting: maximum frequency×0.05% |

| DC braking capability | Starting frequency: 0.00~60.00Hz; Braking time: 0.0~60.0s; Braking current: 0.0~150.0% of rated current |

|---|---|

| Acceleration and deceleration curve | Two ways: linear acceleration and deceleration, S curve acceleration and deceleration; four sets of acceleration and deceleration time, the time unit is 0.01s, the longest is 650.00s |

| Automatic voltage adjustment | When the grid voltage fluctuates, it can automatically keep the output voltage constant |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Instantaneous power failure processing | In case of instantaneous power failure, uninterrupted operation can be realized through bus voltage control |

| Frequency setting channel | Keyboard digital setting, keyboard potentiometer, analog voltage terminal VS1, analog voltage terminal VS2, analog current terminal AS, communication setting and multi-channel terminal selection, main and auxiliary channel combination. |

| Feedback input channel | Voltage terminal VS1, voltage terminal VS2, current terminal AS, communication setting, pulse input PUL |

| Run command channel | Operation panel setting, external terminal setting, communication setting |

| Input command signal | Start, stop, forward and reverse rotation, jog, multi-speed, free stop, reset, acceleration and deceleration time selection, frequency setting channel selection, external fault protection |

| External output signal | 2 relay outputs, 1 collector output, 0-10V output, 4-20mA output, frequency pulse output |

| Protective function | Overvoltage, undervoltage, current limit, overcurrent, overload, electronic thermal relay, overheat, overvoltage stall, data protection |

|---|

| LED display | Dual-line 4-digit digital tube display: It can monitor the status of 2 inverters |

|---|---|

| Parameter copy | The function code information of the inverter can be uploaded and downloaded to realize fast parameter copy |

| Status monitoring | Output frequency, given frequency, output current, input voltage, output voltage, motor speed, PID feedback amount, PID given amount, module temperature, input and output terminal status, etc. |

| Error alarm | Overvoltage, undervoltage, overcurrent, short circuit, phase loss, overload, overheating, overvoltage stall, current limit, data protection damaged, current fault operating status, historical fault. |

| Installation site | Indoor, the altitude is lower than 1000 meters, no corrosive gas and direct sunlight |

|---|---|

| Temperature humidity | From -10 ℃ to +40 ℃ (wall-mounted type), 20% ~ 90%RH (no condensation) |

| vibration | Less than 0.5g below 20Hz |

| Storage temperature | -25~+65℃ |

| Installation method | Wall-mounted |

| Protection level | IP20 |

| Cooling method | Forced air cooling |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| AC Drive PC Software V1.0 | Software | English | ZIP | 2024-02-20 | 46.5MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message