- Home > Product > Industry-specific Drive > Construction Machinery > CH310 Hoisting-specific AC Drive

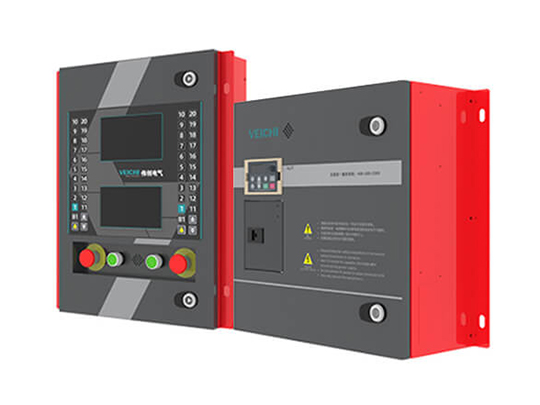

CH310 Hoisting-specific AC Drive

- Power range: 220V/380V/660V: 0.75kW-1120kW.

- High standard processes for high performance and quality high power density for better user experience.

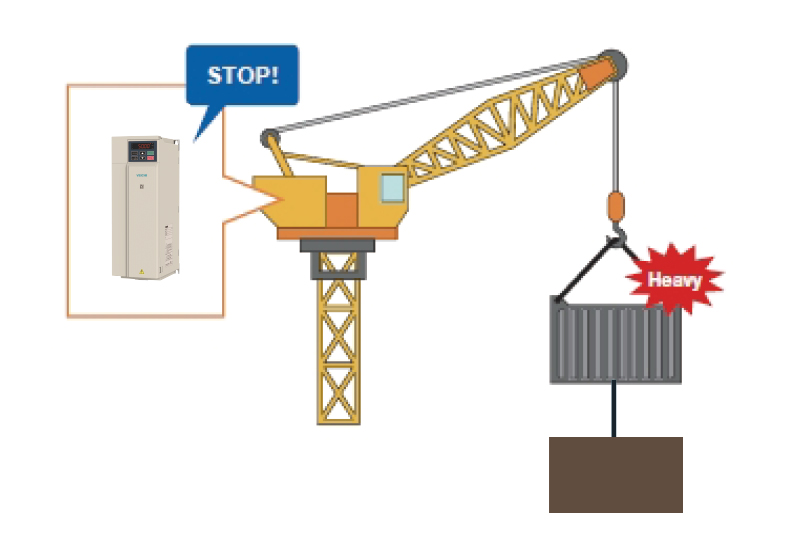

- Low voltage protection for quick stop and operation limit to ensure no hook slippage.

- Software with built-in functions for cart rectification, sync hoisting, precise positioning, grab adjustment, anti-swing, and tower control.

- Precise positioning for optimal efficiency in the designated position without creeping.

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

CH310 Hoisting-specific AC drive

Based on years of experience in the industry, CH310 series features excellent torque control, reliable brake control timing, speed and torque monitoring, power optimization, position processing, intelligent deceleration and more, fully ensuring the safety, reliability and high efficiency of the hoisting appliances in harbor, ships, marine engineering, and mining.

High Reliability

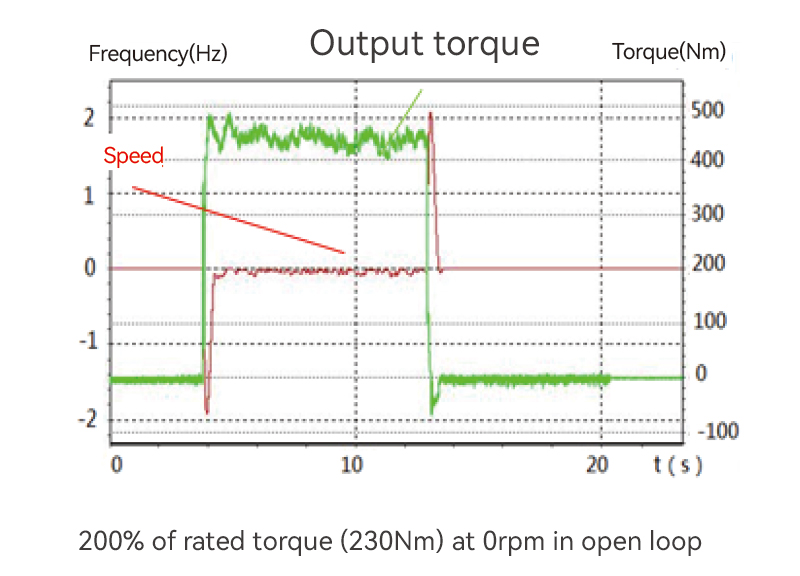

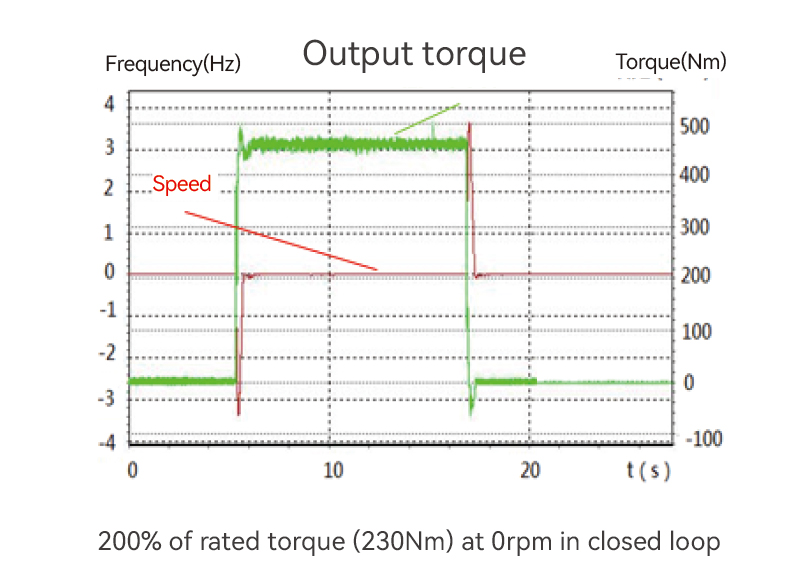

Low frequency and large torque

It can realize 200% of the rated torque output at 0.0Hz, and stable operation with load at the ultra-low speed under 0.01Hz. High torque output for starting ensures smooth ascending/descending process without sliding.

Stable torque output in torque control mode with linearity tolerance within 3% or less.

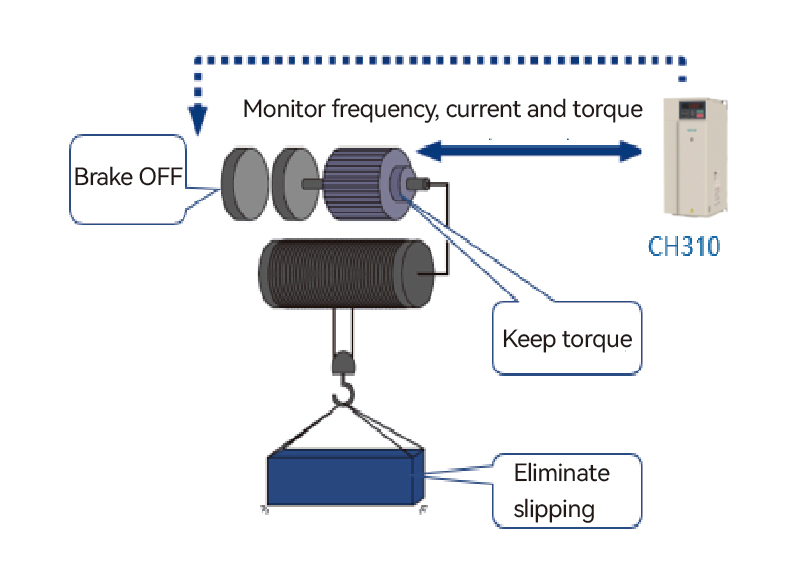

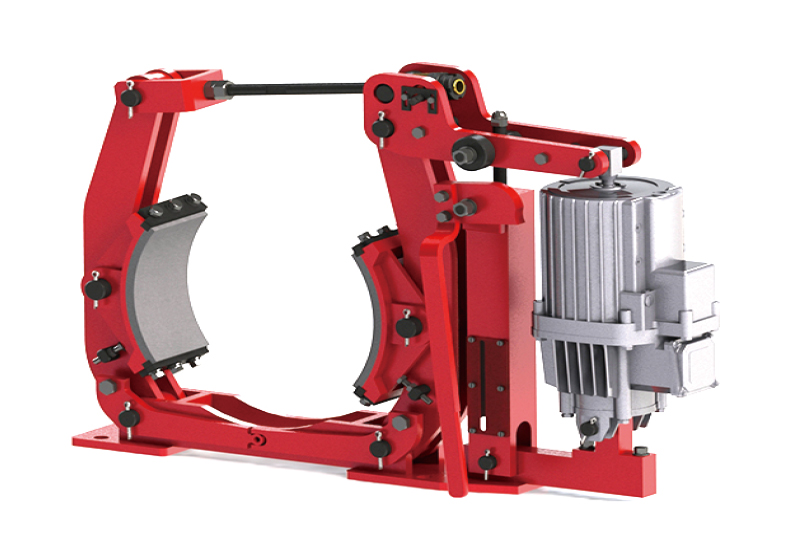

Brake release/apply logic control

The brake will act only when the two conditions of release/apply frequency and release/apply torque are satisfied at the same time to ensure smooth lifting and stopping without slipping.

Steel wire rope protection

Speed is automatically lowered to tighten the wire rope slowly when goods are raised at high speed and the rope is slack, so as to prevent overstretching of the wire rope due to excessive tension, prolonging its service life.

Anti snag

When a sudden increase in load torque is detected during the hoisting process (hanging by a foreign object or being held by an obstacle), an alarm is issued and operation is stopped.

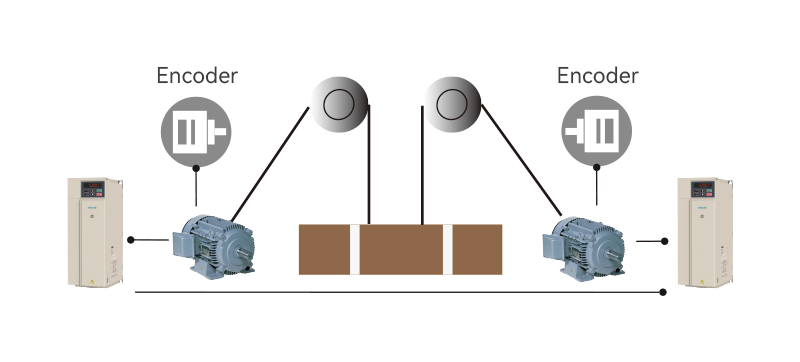

Sync control

Master-slave sync control function: when the dual hoisting mechanism lifts one object at the same time, the master-slave sync control function can ensure that it is lifted synchronously to ensure safety.

Speed Efficiency

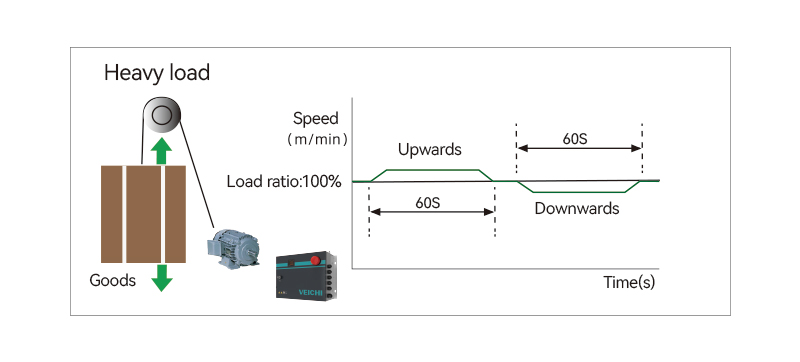

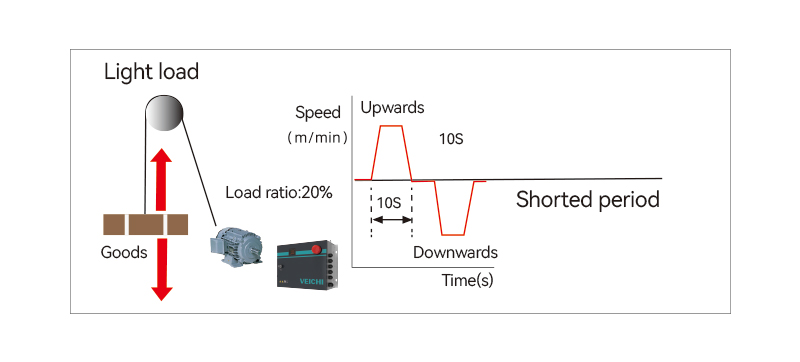

Fast under light duty and slow under heavy duty

Built-in constant power control algorithm (speed change with load ) automatically matches the best running speed according to the current lifting weight, 1-2 times up of the working efficiency.

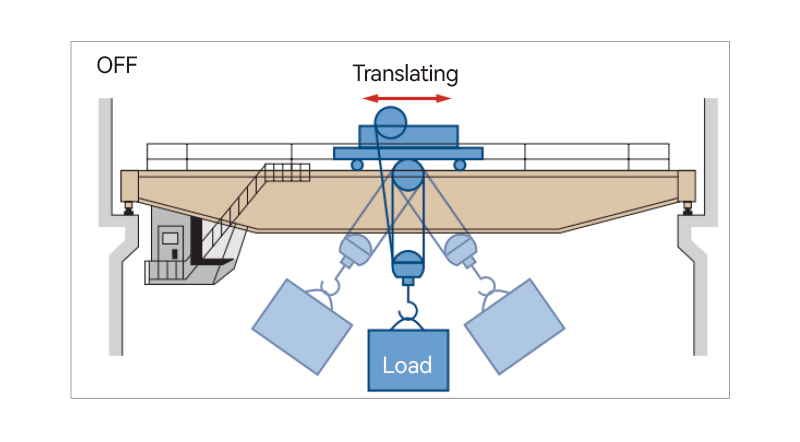

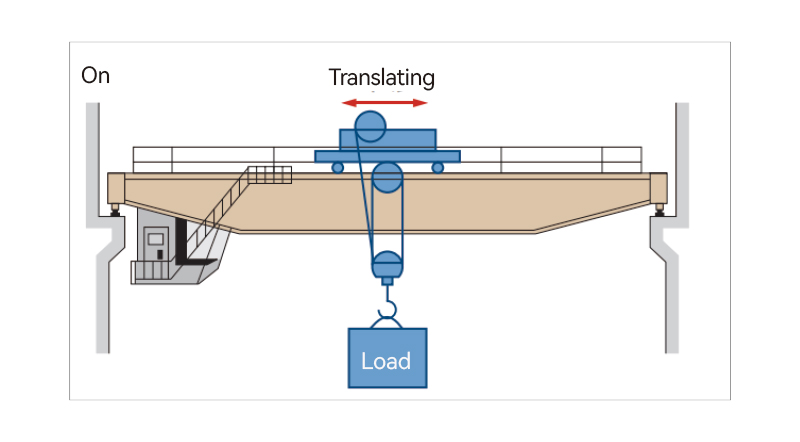

Anti swing

Open/closed loop anti-swing control algorithm with simple debugging and good adaptability reduces hook swaying caused by inertial shock from the cart and trolley and goods swing during translation to keep efficiency and safety.

Turn it on or off by the switch.

Sync control

Master-slave sync control function: when the double hoisting mechanism lifts one object at the same time, the master-slave sync control function can ensure that it is lifted synchronously to ensure safety.

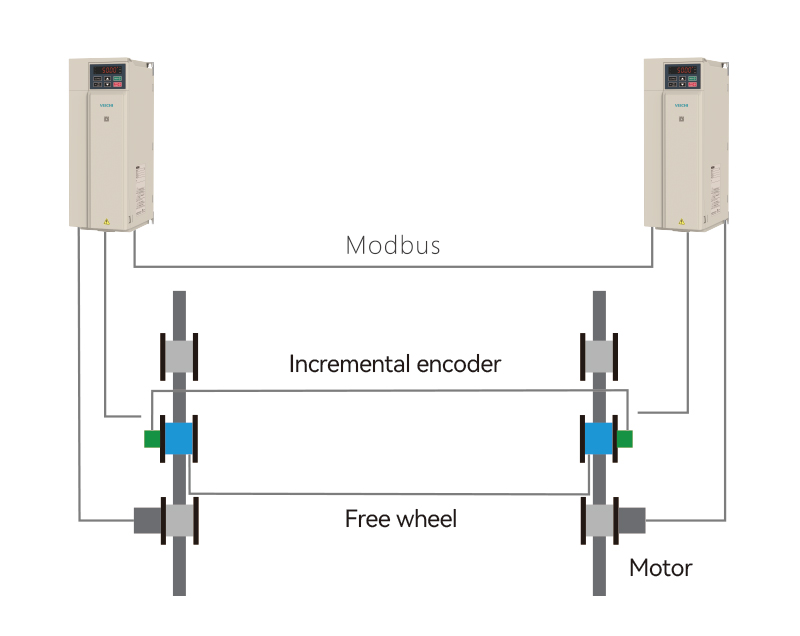

Real-time correction

Real-time position correction is adopted for master and slave for traveling mechanisms with large spans to realize synchronization control.

Anti swing (slewing)

Low-speed slewing is smooth without "stuttering" for quick positioning.

Quick stop with reverse gear (Slewing)

Quick stop can be realized by the reverse gear during slewing without boom shake and rebounce.(for slewing mechanism of tower cranes).

Grab sync control

CH310 AC drives automatically control the grab with a single closing command, the system will close the grab automatically, then adjust tension of the supporting rope and the clamping rope until they are balanced.

Similarly, the clamping of the grab only needs a command, and the system automatically completes it. Its status is determined by the absolute rope difference between the clamping and the supporting ropes, and the deceleration zone is automatically set up to prevent the sudden impact.

High Adaptability

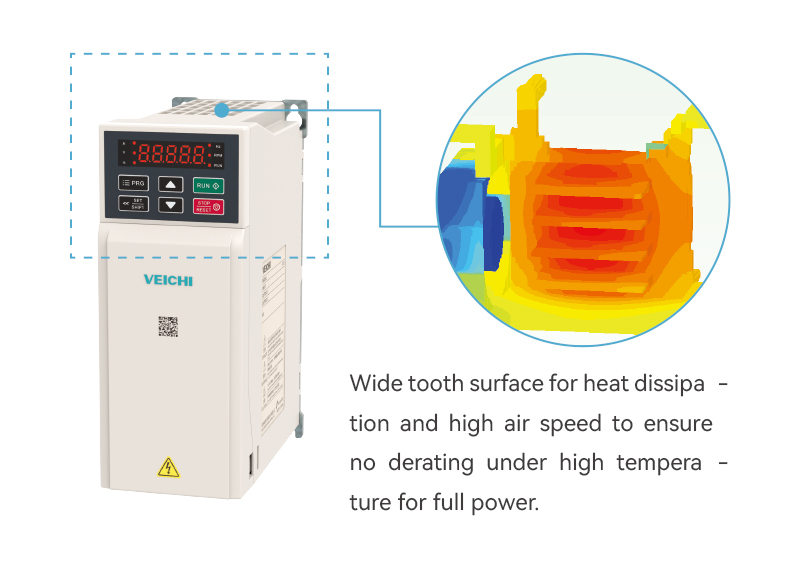

New structure

Wide tooth surface for heat dissipa-tion and high air speed to ensure no derating under high tempera-ture for full power.

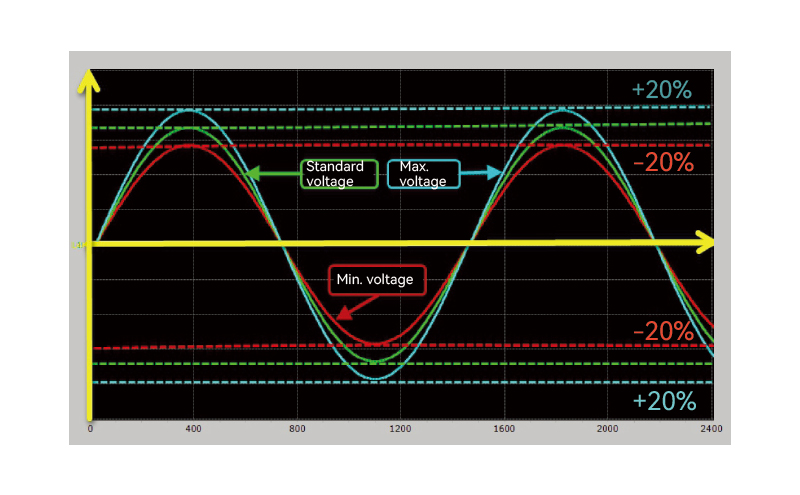

Wide voltage

The allowable fluctuation range of input voltage is ±20% of the standard rated voltage to avoid its influence effectively and at the same time, the output is still qualified under harsh grids.

Superior overload capacity

150% of the rated current for 1 minute, 180% for 10 seconds, and 200% for 3s.

Speed change with voltage

The drive reduces the operating frequency when the supply voltage decreases to keep working.

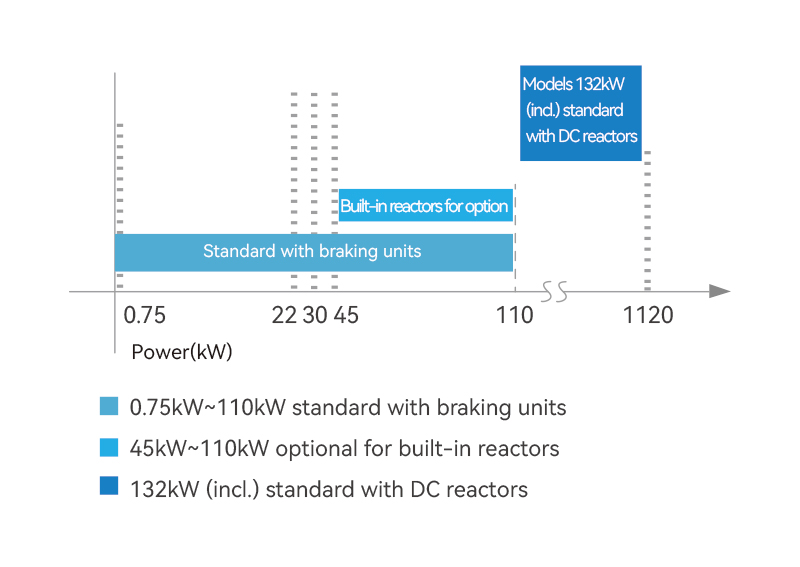

Braking unit and reactor

Power(kW)

0.75kW~110kW standard with braking units.

45kW~110kW optional for built-in reactors.

132kW (incl.) standard with DC reactors.

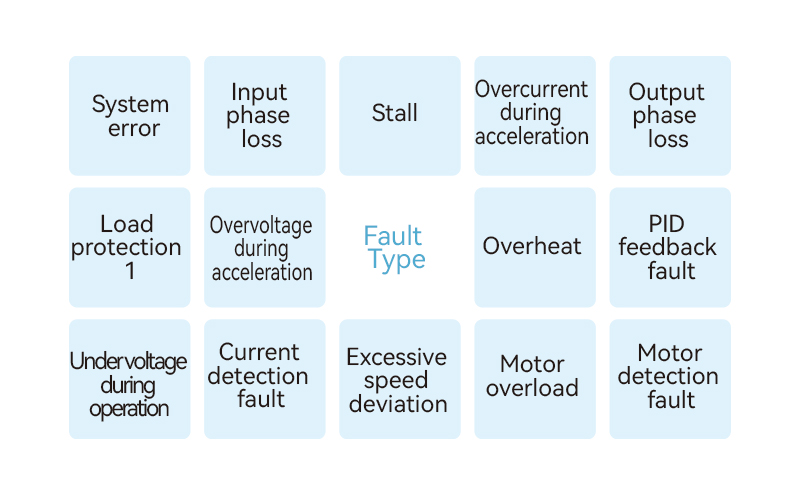

Protection

It realizes all-round protection for the drives and peripheral devices including short-circuit protection to ground, internal buffer relay protection, fan protection, external 24V DC short-circuit protection, motor overload protection and more.

Multiple PG boards

CH310 series supports several encoder interfaces of collec-tor signal, differential signal, and resolver signal for closed-loop vector control.

Expansion

Various expansions

A variety of expansion interfaces are available for customization.

CH310 control board retains two SPI high-speed channels for the external expansions, and its type and parameters are automat-ically recognized.

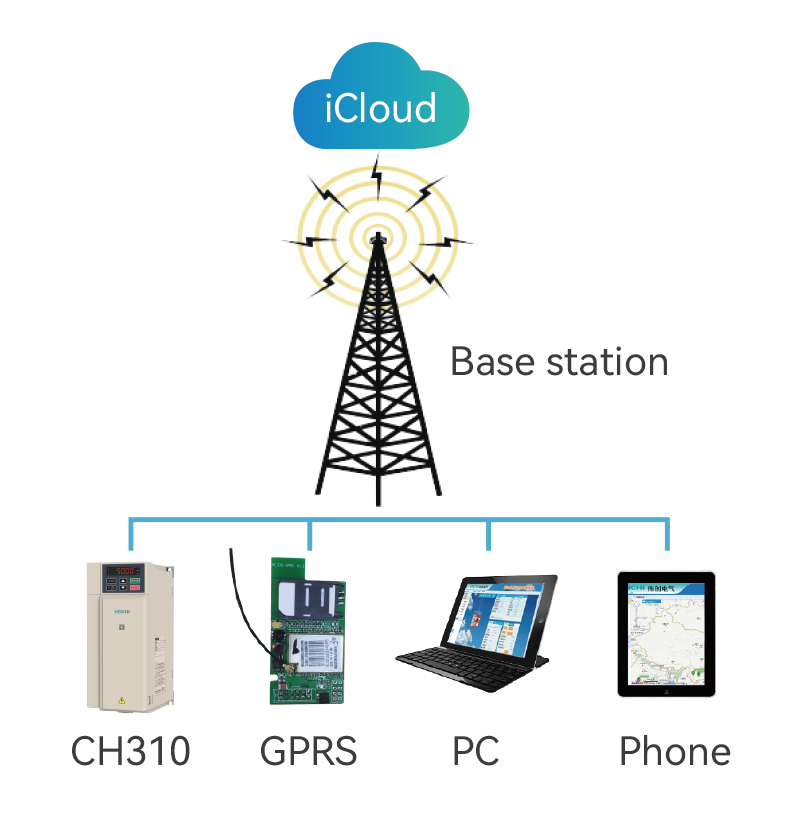

VEICHI lot

Intelligent terminals with high positioning accuracy in small size with easy installation. GPRS and GSM dual-mode communica-tions ensures stable operation and reliable performance. And online monitoring, and remote fault diagnosis are realized through the remote monitoring module, offering customers with a wider range of value-added services.

Logic board expansion

Drive can perform simple logic instead of PLC with the widely used MELSEC programmable controller program development environment integrated with general and compre-hensive function blocks.

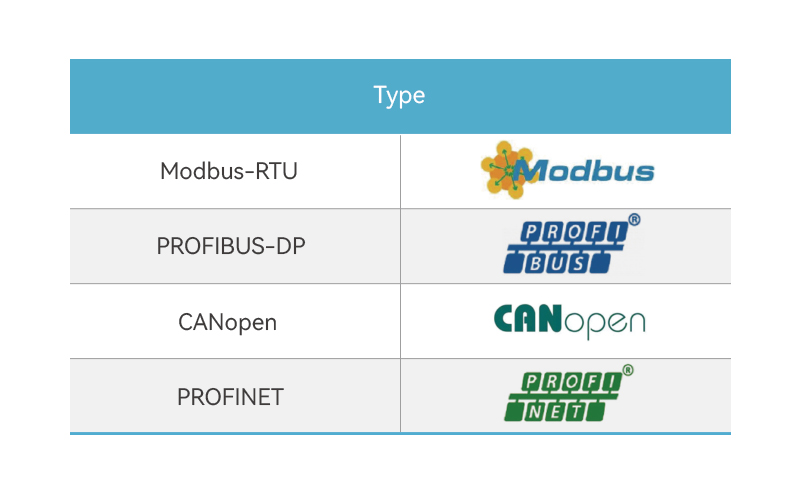

Communication expansion

Industrial Applications for CH310 Hoisting-specific AC Drive

Applications:Rubber tyre gantry cranes, rail-mounted cranes, gantry cranes, general cranes, tower cranes etc.

Specifications

| IO | Optional for high-speed pulse and relay |

|---|---|

| Speed tracking | Voltage imbalance rate: <3%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements |

| Closing impulse current | Optional(software tracking by default) |

| PG | Optional for different encoders |

| Simple logic board | Optional |

| RT Resolver | Optional |

| GPRS | Optional |

| IO | Terminal: X6/X7/X8/X10 Description: PLC/COM |

|---|---|

| High-speed pulse input | Terminal: X10 Description: 0-100kHz |

| DO | Terminal: Expansion port Y2 Description: DC24V/50mA |

| RO | Terminal: Expansion relay TA2/TB2/TC2 Description: 3A/240VAC |

| Temp. detection | Terminal: PK+/PK- Description: PT100/PT1000/KTY84, motor temp. detection |

| Common | Terminal: COM/PLC2 Description: Common port for external appliances |

| Change-over switch | Terminal: S7 Description: Polarity of input terminals |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message