Tower Crane Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Tower Crane Solution

Tower cranes are mostly used in the construction field. The traditional control method uses AC wire-wound motors with series resistance to start and adjust the speed. Due to the long term heavy load operation, frequent forward and reverse operation and gear shifting can cause serious mechanical and electrical impacts.

VEICHI has designed a solution for tower cranes with a general squirrel-cage AC motor, which is cheaper than a wire-wound motor. Moreover, it will greatly reduce the deformation of the steel structure caused by torque and fundamentally solve the problem of high failure rate of tower cranes.

Features and Benefits

VEICHI Tower Crane Solution

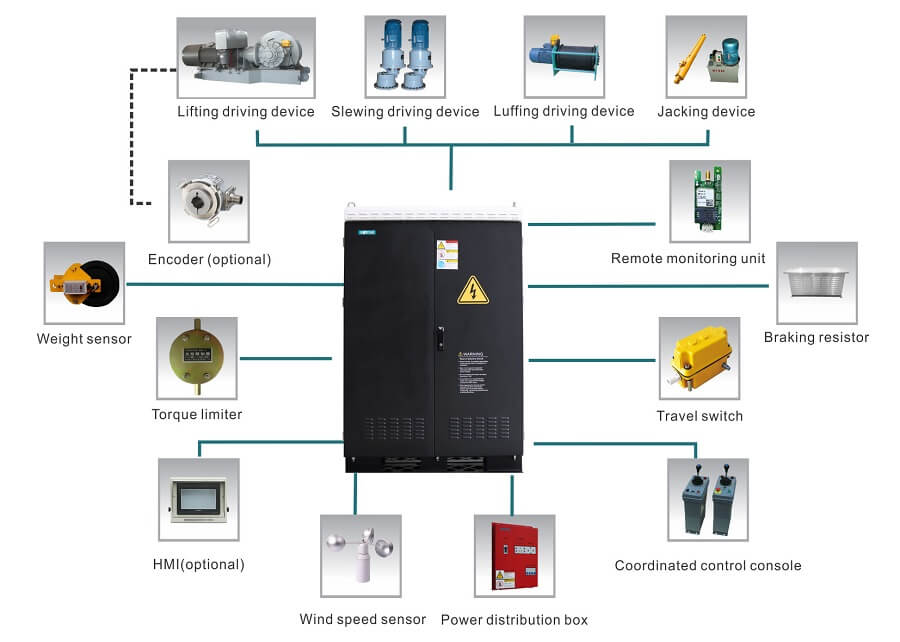

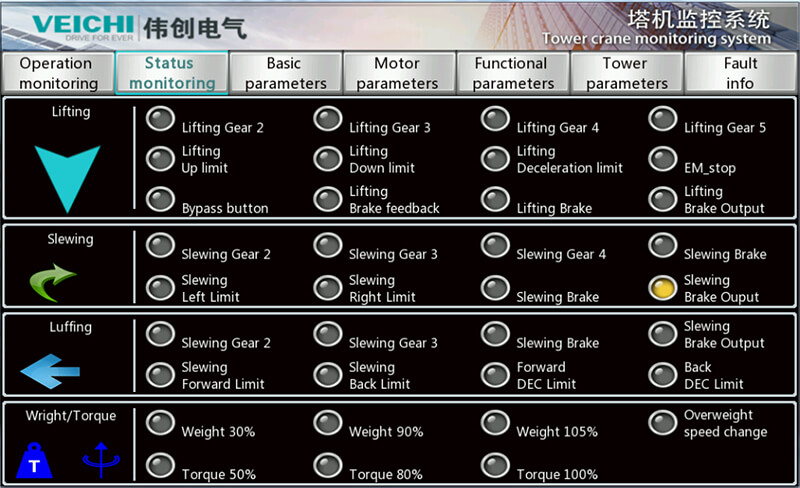

Industry first-integrated tower crane drive, a mid-to-high level model that is specifically designed for the modular control of tower crane’s electrical control needs. It integrates three major mechanisms: frequency inverter control unit, PLC logic control unit, and black box monitoring unit (expansion). Tower crane solution. With a characteristic of intelligence, lightweight, high efficiency and energy saving, safety and reliability, the integration of tower crane dedicated Inverter is bound to be the new trend of the industry’s future development.

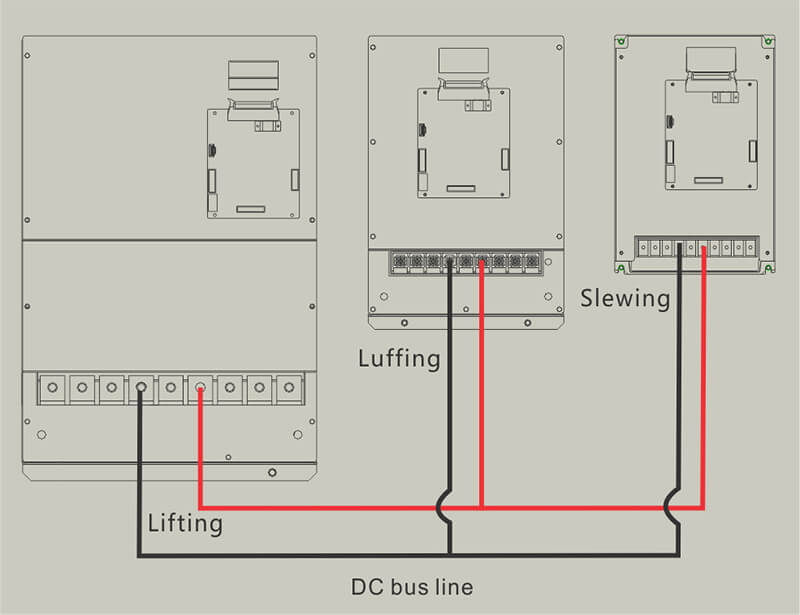

Built-in common DC bus technology

When the lifting mechanism is dropping the heavy object, the energy returned from the motor can be used for slewing and the luffing mechanism, thereby achieving the purpose of energy saving.

Tower crane black box function

Compatible with GPS and Beidou satellite precise positioning, real-time recording of tower crane operation status, overload times and real-time data, local storage, and upload to IOT platform at the same time.

Intelligent man-machine interface and voice prompt function

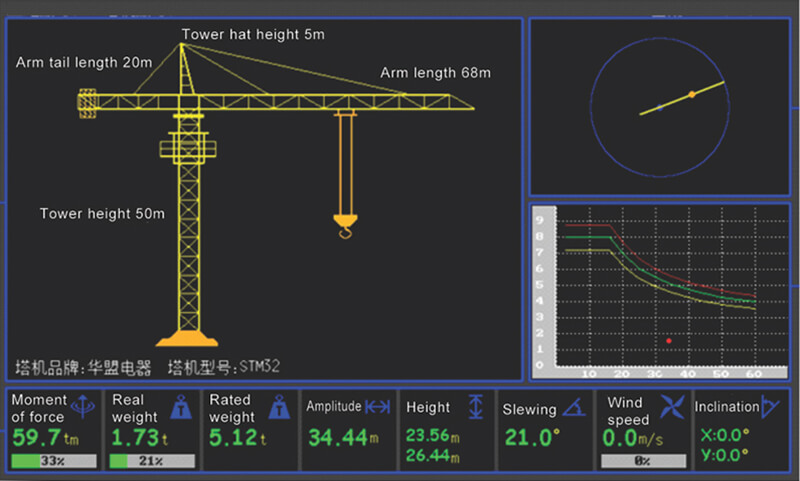

• Equipped with 10 inch touch screen (HMI), it can display various master commands, limit status, inverter monitoring data and related function buttons; friendly HMI, simple and easy to operate.

• The intelligent voice prompt system can cyclically broadcast various fault states and processing countermeasures, operation prompts and warnings through live pronunciation.

Ground remote control operation

• The driver can use the "local / remote control" selection switch on the linkage platform to give control power to the ground operator for remote control operation, so as to realize the ground wireless control tower crane.

• The system needs to add a set of wireless remote control operator.

Solution Topology

VEICHI QT series tower crane control system has specially developed with modular design: the lifting, slewing and luffing control module run independently without interference. Besides, it has been integrated with IOT control unit.

Doing Business

As an important mechanical equipment in the construction industry, the safe use of tower cranes will directly affect the reputation of tower crane manufacturers and the progress of on-site engineering. The successful application of the tower crane variable frequency integrated drive fundamentally solves the problem of high tower crane failure rate. The tower crane variable frequency integrated drive can not only safely supervise the tower crane, but also improve the working efficiency and safety of the tower crane. Tower crane frequency conversion integrated drive will be a trend of future intelligent development of tower cranes, VEICHI will provide a full set of professional suggestions and technical solutions for users' reference.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message