- Home

- VEICHI News

- VEICHI Intelligent Manufacturing Draws Extensive Attention at the China CNC Machine Tool Fair(CCMT)

On April 8, 2024, the China CNC Machine Tool Fair(CCMT), a significant window and platform for machine tools and further demands investigation, grandly opened in Shanghai. Centered around the theme of "Digitalization · Interconnection · Intelligence," the fair is about to inject innovative, digital, and integrated forces into the development of the numerical control machine tool industry. VEICHI Electrical, a committed player in the high-end CNC machine tool industry, presented a range of high-performance products and solutions featuring digital and intelligent integration tailored for various scenarios to realize quality production with the innovative outcomes for customers.

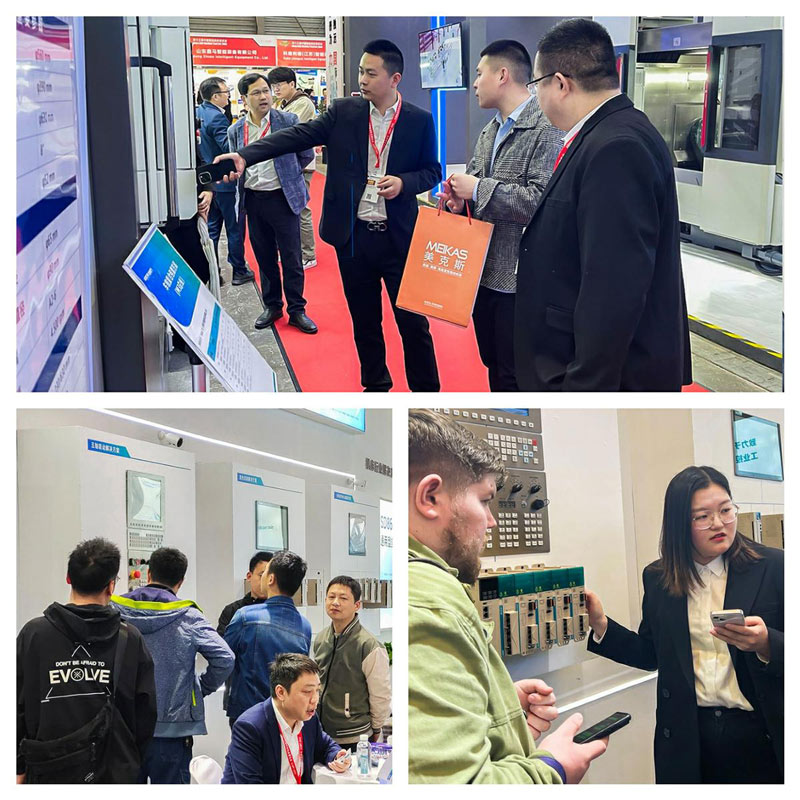

Exhibition site pictures

In response to the industry's demand for higher level of development in machine tools, VEICHI Electrical, presented dedicated products such as the V800 series CNC system, SD700 series high-performance servo drives, SD860 series universal multi-drive systems, along with comprehensive digital system solutions based on its automation and intelligent technologies. Advanced solutions of five-axis linkage, turning-milling composite, electric bending centers, and laser cutting showcased by live demonstrations and technical exchanges highlight the efficiency and accuracy in VEICHI products, which received high praise from clients and peers.

Innovative Product Showcase

Five-Axis Linkage Solution

Advantages:

1. Multi-axis linkage for more flexible motion and more complex surface machining.

2. Tool tip following, characteristic plane control, and smooth tool axis vector algorithm for higher machining precision.

3. Constant speed machining for higher efficiency.

4. Complex components machining capabilities for wider application.

Turning-Milling Composite Solution

Advantages:

1. Dual channels, dual spindle sync for dual spindle dual turret, or dual spindle single turret and such.

2. Five-axis linkage for high-precision curves and complex machining of turning-milling composite.

3. Main servo equipped with dual encoder interfaces to suppor M3/EtherCAT bus, compatible with pulse incremental and sinusoidal encoders.

4. Compact motor structure with large output from the power head and smoother milled surface.

Electric Bending Center Solution

Advantages:

1. Unique algorithms and strong overload capability of the servo motor for the benders.

2. Internationally leading current loop algorithms in the servo drive for faster and more precise response.

3. Various bus solutions for more solutions and easier wiring and commissioning.

4. Industry-leading motor sync algorithms with max motor speed increased by 50%.

Laser Cutting Solution

Advantages:

1. Servo motor paired with high-resolution encoders with model tracking to deliver faster response and higher precision.

2. Customized motors with small axial runout for smoother high-speed operation under load for the machine tool industry.

3. Various bus solutions for more solutions and easier wiring and commissioning.

4. Industry-leading motor sync algorithms with max motor speed increased by 50%.

In the future, VEICHI Electrical will continue to delve deeply into the field of industrial automation, and launch more innovative products and solutions to provide strong technical support for the intelligent, digital, and energy-saving transformation of manufacturing.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message