- Home

- R&D Innovation

- A Transformation of Process Innovation-Weaving Direct Drive Electric Spindle System of VEICHI

In the context of the international economy, how to improve the profit of the weaving industry?

Let every textile entrepreneur think hard.

Bargaining with raw material chemical fiber suppliers?

Still saving labor costs?

Is it to reduce the cost of business operations management?

Or do you work hard on the annual astronomical electricity bill?

The author replies to you: I can't help the first point, I will stay with you in the last three points.

Official announcement! Equipped with VEICHI "core" direct drive electric spindle system!

For the weaving industry to enter the intelligence of the equipment came into being.

Why use "transformation" to describe the direct drive electric spindle system?

The author takes you all to know.

Since it is "transmutation", it is necessary to lead the industry.

Drive for ever

★ Includes permanent magnet synchronous direct drive controller and direct drive electric spindle MD-motor;

★ Built-in tension control algorithm for electric power transmission, supporting double delivery, left and right, upper and lower warp beam;

★ Water jet weaving electrical control system covering digital weft detection and weaving navigation expert database.

Direct drive motor

Since it is "transmutation", it is necessary to save energy and reduce emissions.

Energy conservation

Application scenarios

The direct drive electric spindle MD-motor of VEICHI came into being and carried the craftsman spirit. Compared with the traditional asynchronous spindle motor, the MD-motor system has the following advantages:

★ Direct drive electric spindle system sampling AC permanent magnet synchronous motor, the system efficiency is up to 95%, and the high efficiency range of operation is 20%-125% of the rated load. Eliminate reactive losses and save energy.

★ The electric spindle direct drive transmission eliminates the brake disc and the belt pulley, further reducing the transmission wear. The energy saving rate of the VEICHI direct drive electric spindle system is as high as 20%-30%.

★ The electric spindle system can adjust the speed of the loom steplessly, and can improve the speed of the weaving machine while increasing the speed of 10-30r/min. Taking the speed of 500r/min as an example, 1000 loom is equivalent to 20-60 loom. In operation, don't be underestimated!

★ Inching, slow search, and start-stop function at a fixed angle can not only protect the high-speed hitting problem of the blocker, but also improve the best angle problem of the weaving machine.

Energy saving! The average power consumption per looms is 3,000 yuan / year

Then count the saved safety work, change the damage of the belt brake pads,

The company's annual net profit is more than 3.5 million (1000 units)

Since it is "transmutation", it is necessary to be cutting-edge technology.

All-in-one control

Weft feeder

★ The weft insertion unit control, the weft feeder, rotary valve and gripper are all driven by the main controller. The customer does not need an external weft feeder power box to reduce the procurement cost.

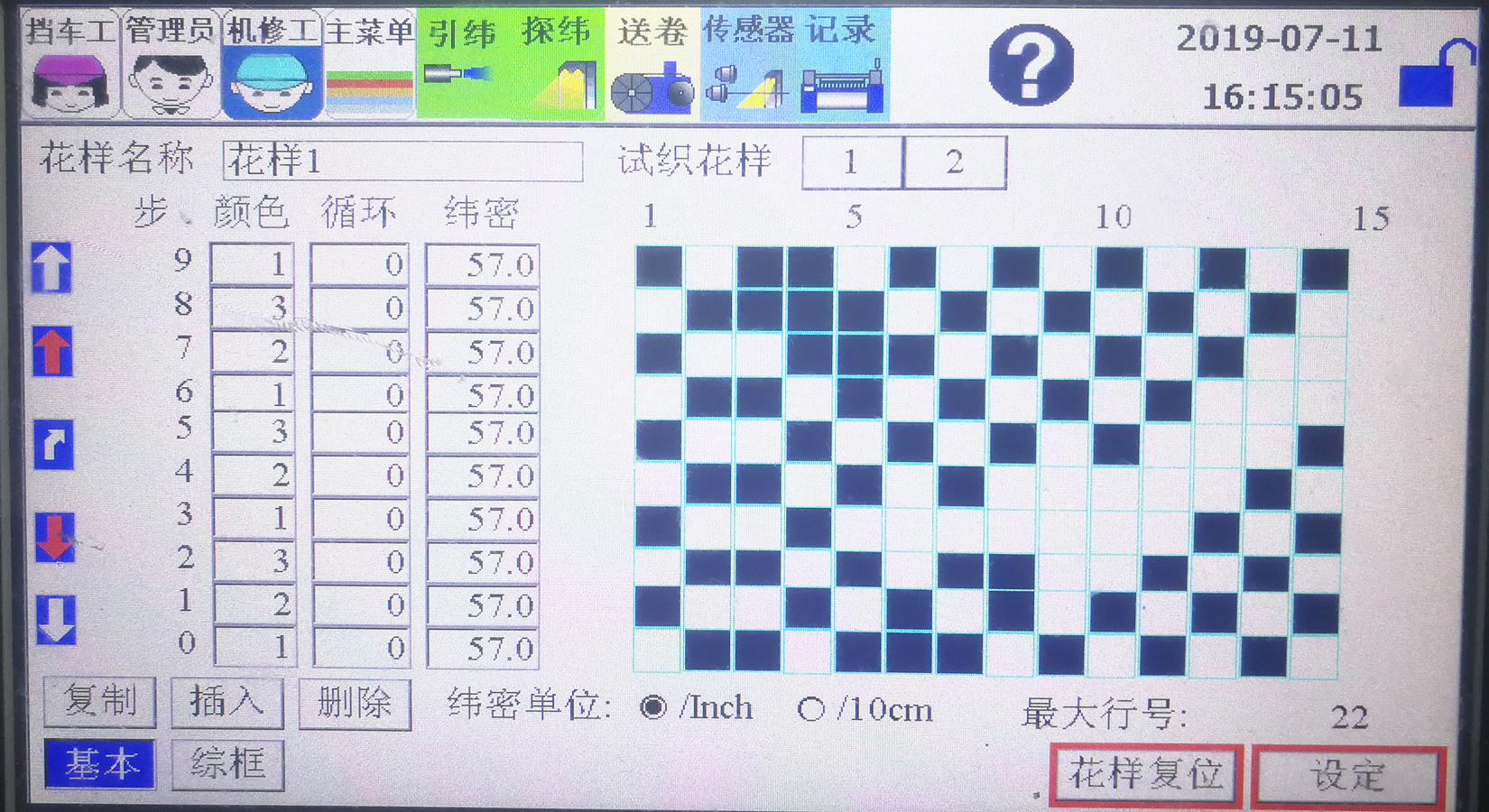

★ Standard electronic multi-arm, electronic jacquard control, you can write the weaving sample through the host computer without the need to purchase the multi-arm control box, jacquard control box.

★ Support variable speed and weft weaving.

★ Six-stage super-starting torque and eight-stage adjustable speed.

Operation interface 1

Operation interface 2

Since it is "transmutation", it is necessary to craftsmanship.

Process + industrial control

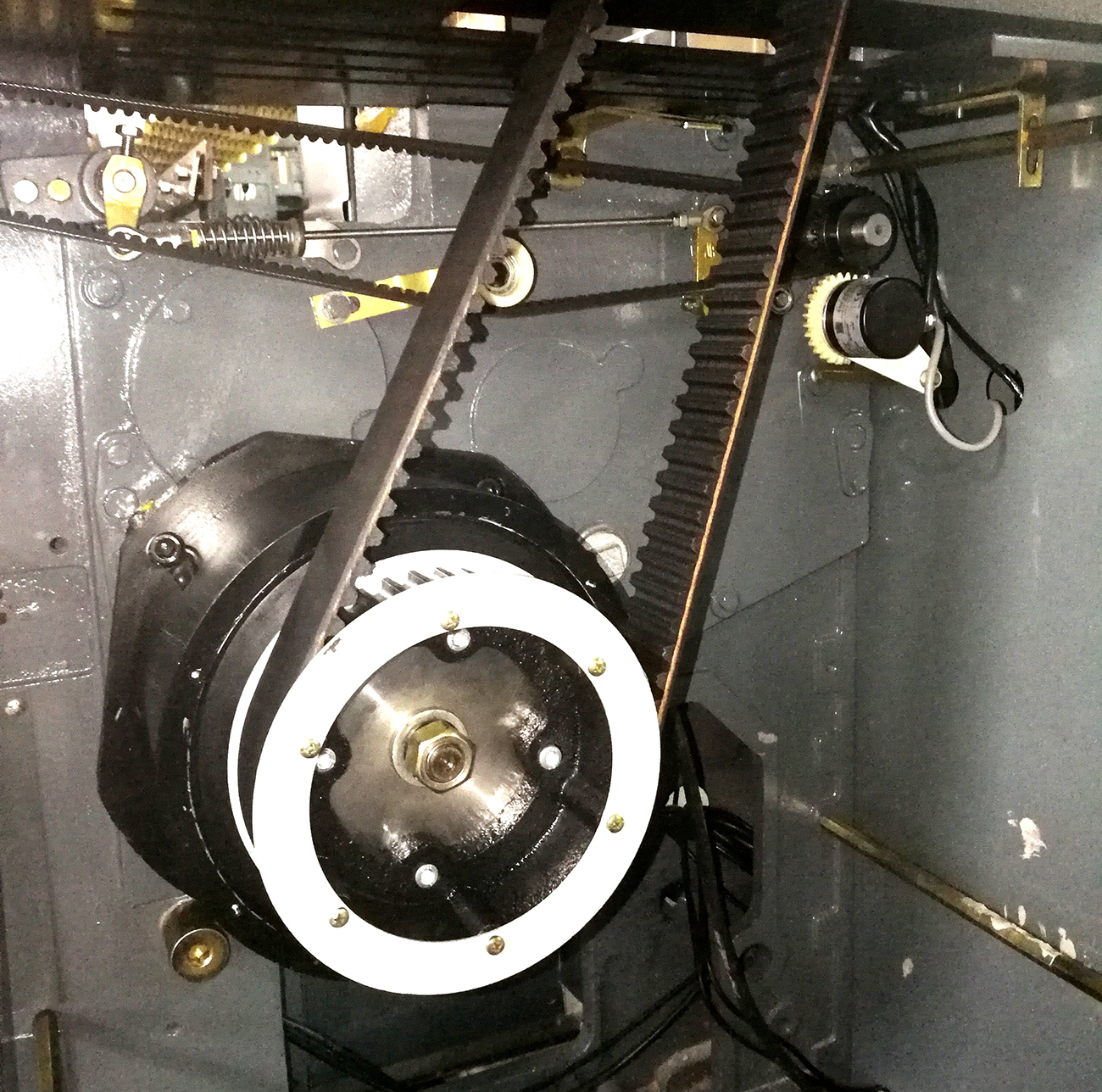

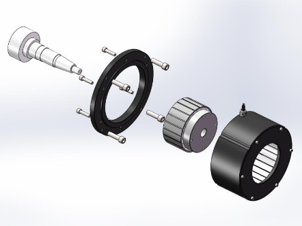

Direct drive electric spindle

★ Direct drive electric spindle adopts vacuum sealing and filling, which can run in water for a long time;

★ Rotor magnet is made of permanent magnet material, which can run for up to 24 hours at 150 ° high temperature without demagnetization;

★ 2.2kw-5.5kw motor power segment to meet customer energy-saving transformation needs.

The electric spindle controller

The electric spindle controller not only has a value but also high protection.

It has an ultra-high waterproof and cotton-proof grade.

It is perfectly adapted to the severe use environment of water jet and air jet looms and stable operation.

Since it is "transmutation", it is necessary to overcome the barriers.

Victory over barriers

Often when it comes to parking, customers feel that the factors are too many and too complicated. Once they are met, they will not be able to start. It may be because the machine is too old, the vibration is relatively large, the gear is too long, the tension is too long, the tension is too small, the gear is too small, the super-start gear is wrong, and so on, causing the customer to talk about the "block" color change.

At this stage, the production capacity determines the survival of the enterprise, and the quality determines the development of the enterprise. Only by solving the parking gear can we produce high-end varieties of woven fabrics and improve the quality of the products. The author is here to give you a move to control the parking lot: automatic weft search, fixed angle driving rocker, reverse control, downtime tension compensation, electronic delivery and coiling 0.01 latitude compensation.

VEICHI servo drive

VEICHI servo motor

Since it is "transmutation", it must be statistical management.

Statistical management

The foothold of textile enterprises lies in workshop management, production management, order management, and how to manage enterprises through cloud platform technologies such as modern statistics and IOT. Today, the author leads everyone to find out.

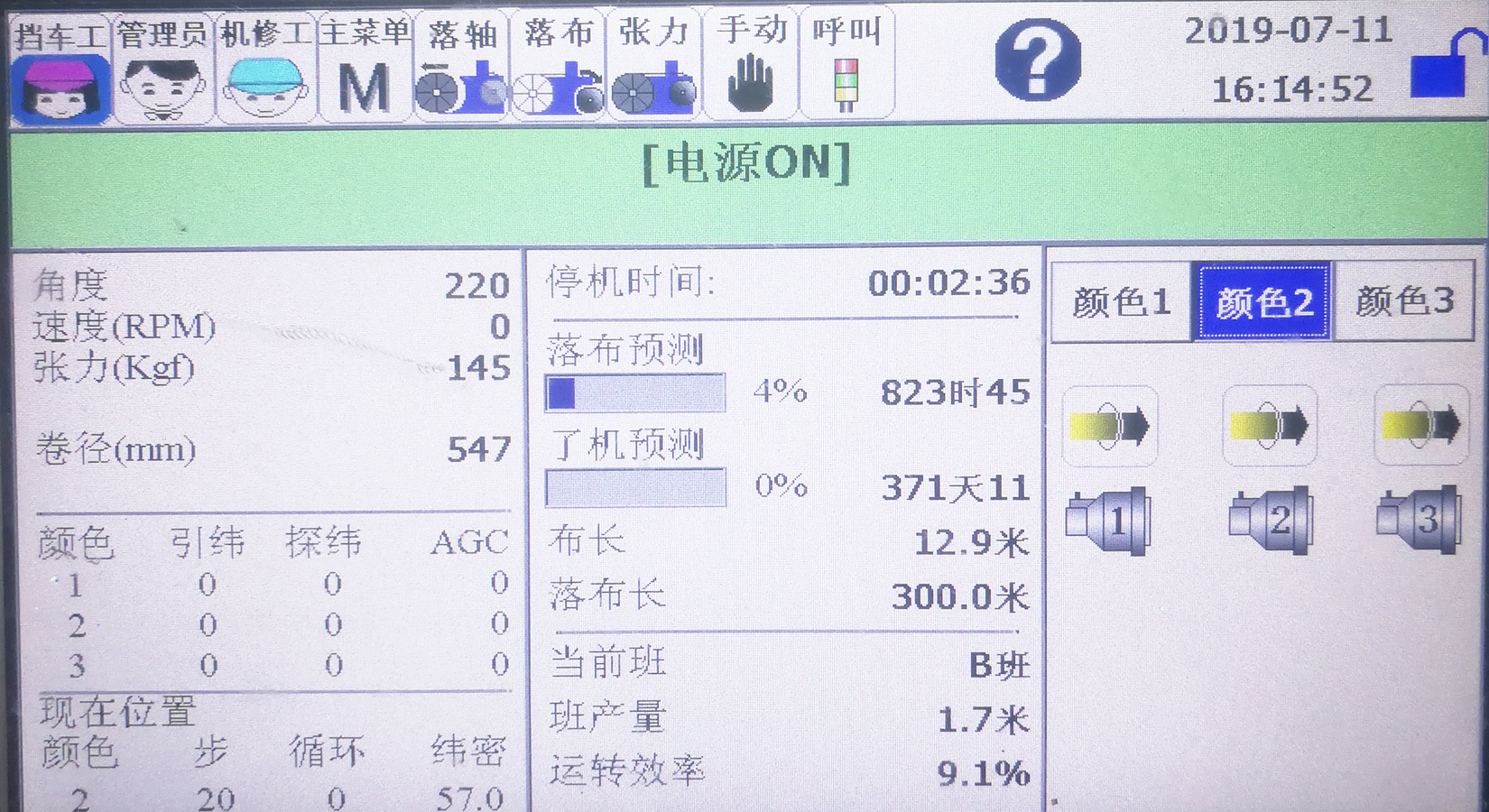

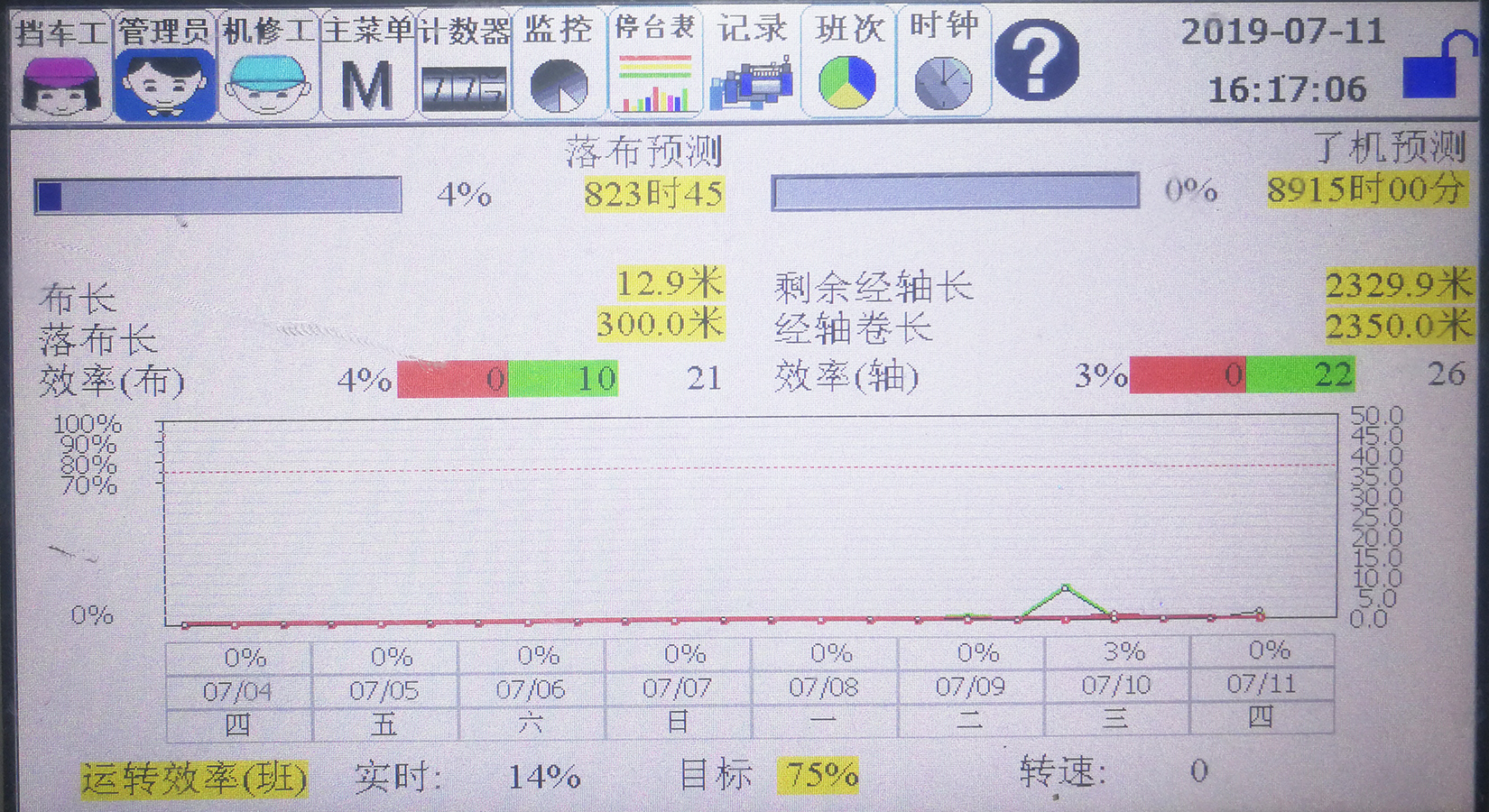

Operation interface 3

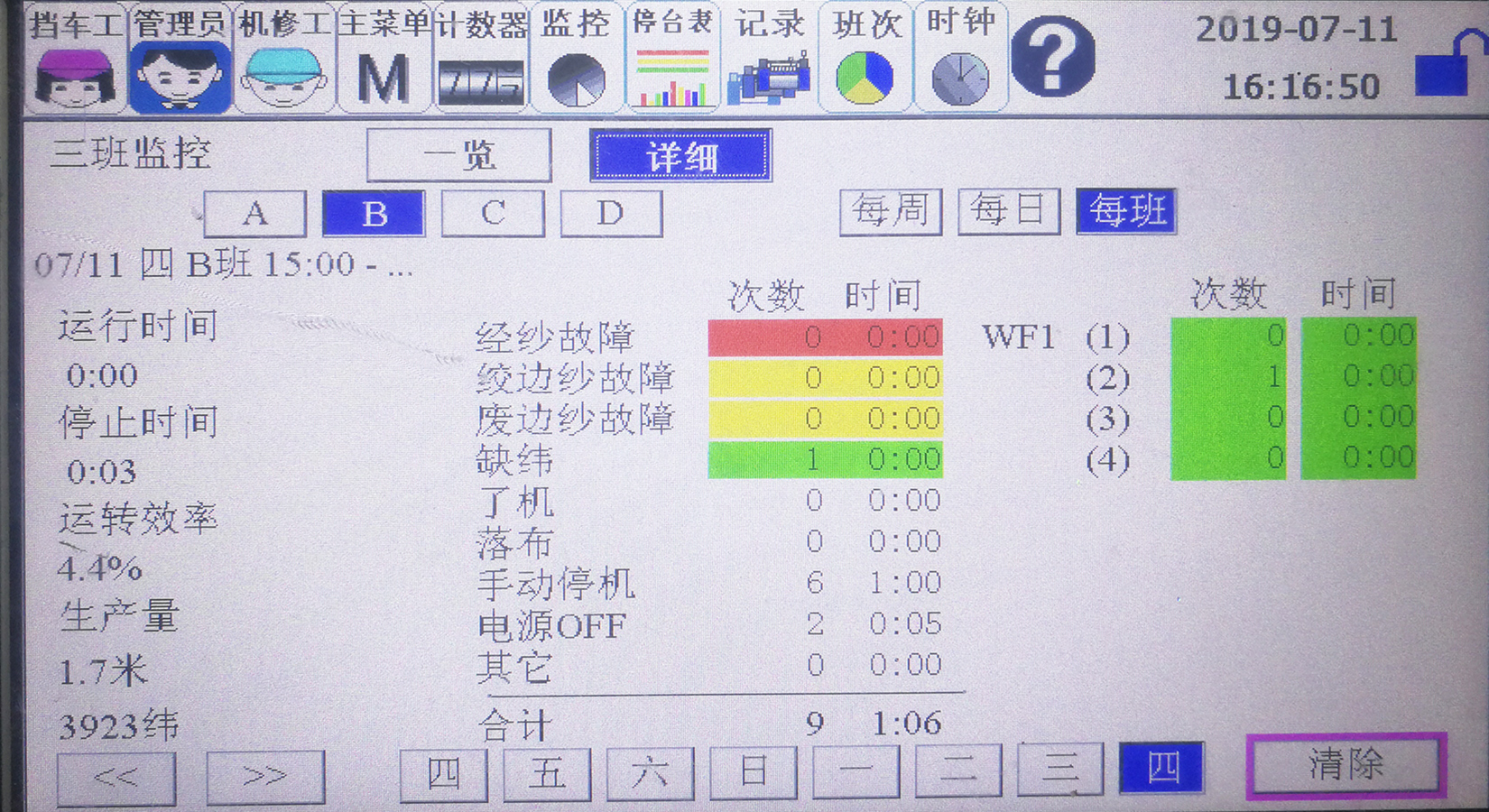

Operation interface 4

Rich data statistics management function, record the efficiency of one week, parking type; through data analysis, output corresponding solutions and improve machine efficiency recommendations; remote monitoring of home machine speed and efficiency through APP, IOT.

Through the capacity analysis, the database is established; the corresponding product capacity report is output, and the sales side order forecast analysis is provided to realize the ERP management; the rich performance and the machine efficiency shift statistics are convenient for the workshop personnel management.

More exciting, so stay tuned!

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message