- Home

- R&D Innovation

- Major Breakthrough on VEICHI Electric Synchronous Motor Open-loop Control

Various eco-friendly and energy-saving policies and measures have become a prevalent civilization development trend. With regard to the social benefits of high-efficiency motor energy conservation, our country has proposed to impose high-efficiency motors on the policy view. And with the energy conservation and environmental protection initiatives and the enhancement of industrial level, high-efficiency synchronous motors are rapidly emerging that is ongoing replacement of existing low-efficiency motors and has become a major source of power for drive equipment gradually. High-efficiency synchronous motors are in the ascendant in many industries such as air compressors, oil field pumping units, textile equipment, mining equipment, etc.

China Energy Efficiency Label

VEICHI Electric takes the development demands of the industrial control field into consideration and continues to introduce new products. The newly launched AC300 frequency inverter integrates the open-loop and closed-loop control of the synchronous motor as it was upgraded from the performance of the VF control, open/closed-loop vector control of the asynchronous motor. It makes the AC300 series frequency inverter a special product that combines the multiple controls firstly among mainstream domestic brands.

Synchronous motor direct drive technology in the coal field (encoder installation is difficult and not easily maintained in mine environment

In the closed-loop control of the synchronous motor, the performance of the starting torque in closed-loop control wouldn’t be great if the conventional photoelectric encoder has a less number of points. The use of high-precision encoders is extremely costly and the decoding chip of accompanying drive device is also very expensive. Many factors have caused the closed-loop control of synchronous motors to be limited. Through continuous technological breakthroughs, finally VEICHI solved this problem successfully by applying the high-frequency signal injection method.

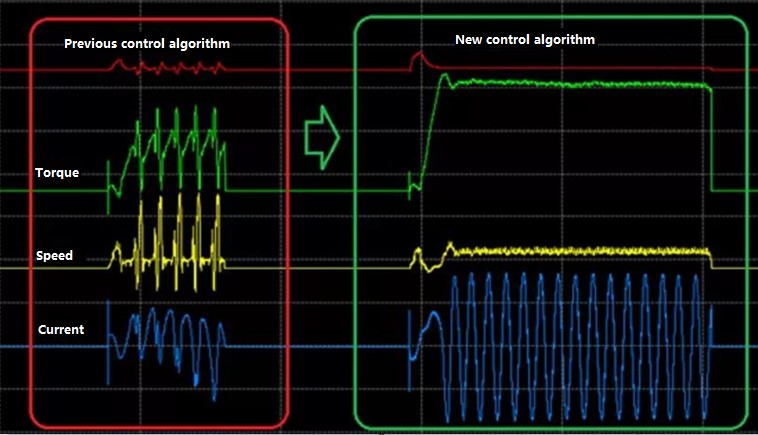

Comparison of high frequency voltage injection before and after when the motor is overloaded

Under heavy load conditions, the speed of the device is very low and the conventional synchronous drive cannot start in open-loop control. VEICHI AC300 frequency inverter injects high-frequency voltage during open-loop operation to realize the effect of closed-loop control. VEICHI Electric overcame this difficulty and achieved synchronous motor open-loop control of 200% torque output at 0Hz. VEICHI Electric is also the first company in the domestic inverter industry to generalize this technology and has reached the international advanced level.

Saving energy for the society, saving costs for customers and facilitating using are the driving force behind VEICHI's breakthrough in electrical technology. We will continue to forge ahead and provide customers with better products.

[Note: SPM: surface-mount permanent magnet synchronous motor and relatively simple structure; IPM: built-in permanent magnet synchronization and the structures are relatively complex but better performance and functionality. SPM adopts high-frequency injection to achieve closed-loop control that is indeed more difficult (because the salient pole rate is <10%), IPM with high-frequency injection method goes very well.]

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message