- Home

- R&D Innovation

- The IOT remote monitoring and management system of VEICHI

System overview

The IOT remote monitoring and management system of VEICHI is a self-developed, multi-layer architecture design, real-time, reliable, secure, scalable and other reasonable hierarchical design of the IOT monitoring system that can be remotely monitored, managed, maintained and analyzed. The interface is friendly, simple to operate, full-featured, compatible with all products of the company, and also meets the access of some specific devices. It can solve various problems in the various industries due to the complicated environment of the equipment, resulting in problems such as management, maintenance and monitoring, making the work smarter and more efficient.

System structure

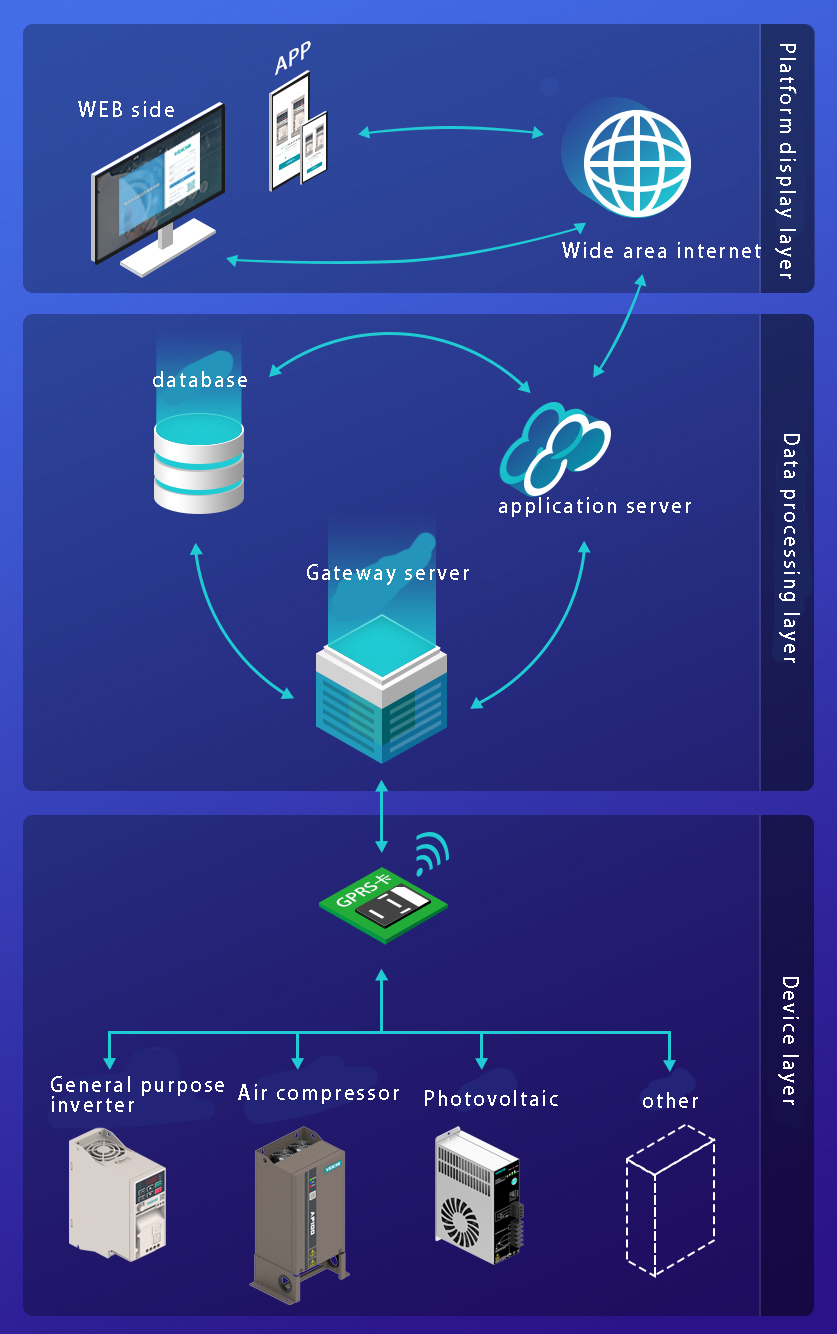

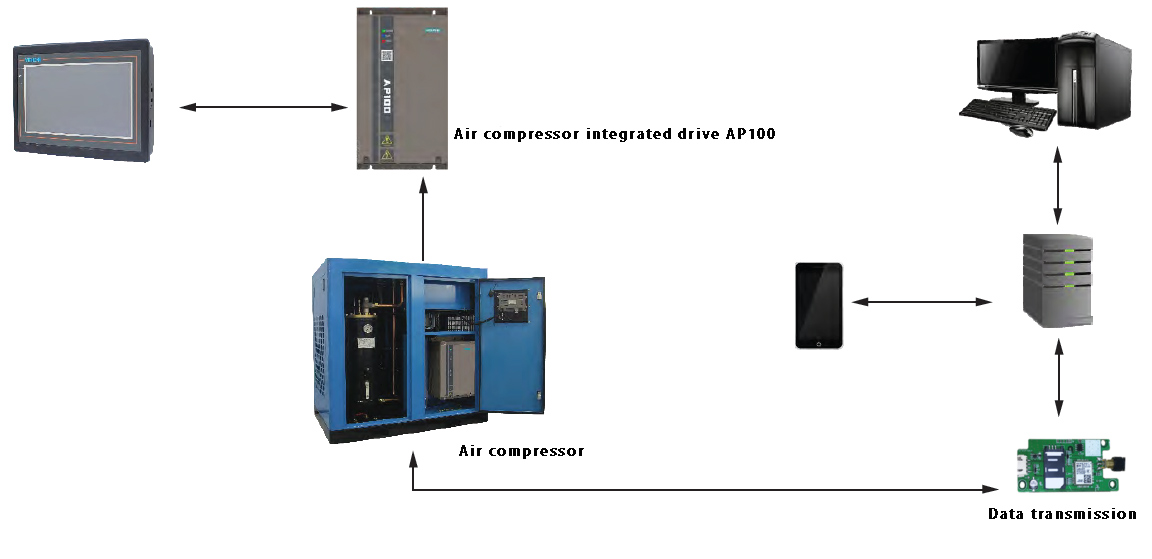

The basic architecture of the VEICHI IOT system is shown in the following figure. It consists mainly of the device layer (device, wireless data transmission module), data processing layer (gateway server, application server, and database) and platform display layer (WEB + mobile APP). The wireless data transmission module is used as the transmission medium, and the data interaction between the device end and the background server is connected, and the wide-area network is not restricted by the geographical limitation, and finally the purpose of remote intelligent supervision is achieved. VEICHI IOT system has wide applicability and scalability, and can be applied to general-purpose inverters, special inverters (such as air compressors, photovoltaic pump inverters, elevators and tower cranes), servos, PLC, etc. To help customers' production and services move toward digitalization and intelligence.

The basic architecture of the VEICHI IOT system

2.1 Device layer

The device layer includes devices and wireless transmission modules.

Device

Including general-purpose inverters, special inverters (such as air compressors, photovoltaic pump inverters, elevators and tower cranes), servos, PLC, touch screens, etc. of VEICHI, all support wireless transmission module access, and the following are some introduction about products:

General-purpose frequency converter: used for frequency conversion to adjust motor speed, widely used in various industries, such as construction, textile, packaging, machine tools, chemical, cable and other industries, currently has AC10, AC70, AC200, AC300 and other products. The company's product features: fast start and stop, smooth and stable, can drive a variety of loads (synchronous, asynchronous, electric spindle, AC servo), covering V/F control, pressure and frequency separation, open and closed loop vector, free choice of speed and torque, etc. The control mode adopts the international leading self-learning algorithm, which is precise and consistent, supports multiple types of expansion cards, and is suitable for various occasions.

VEICHI general-purpose frequency converter

Air compressor: mainly used in pneumatic and pneumatic control scenarios, currently available AC100, AP100 air compressor series products. The company's product features: integrated host, fan, oil temperature fan, using TI high-performance DSP chip, more reliable, less noise; under the supply pressure, the minimum operating current, maximum output, energy saving; GPRS wireless transmission technology, real-time remote monitoring of air compressor field application, intelligent fault detection, SMS notification; in the operation can directly monitor the motor magnetic field, timely warning, reduce the probability of motor loss of magnetism; with motor temperature monitoring to prevent PMSM from overheating Irreversible degaussing; high protection level, preventing high temperature caused by oil stains, metal dust and cotton wool, suitable for harsh occasions such as machine tools and textiles.

VEICHI AP10

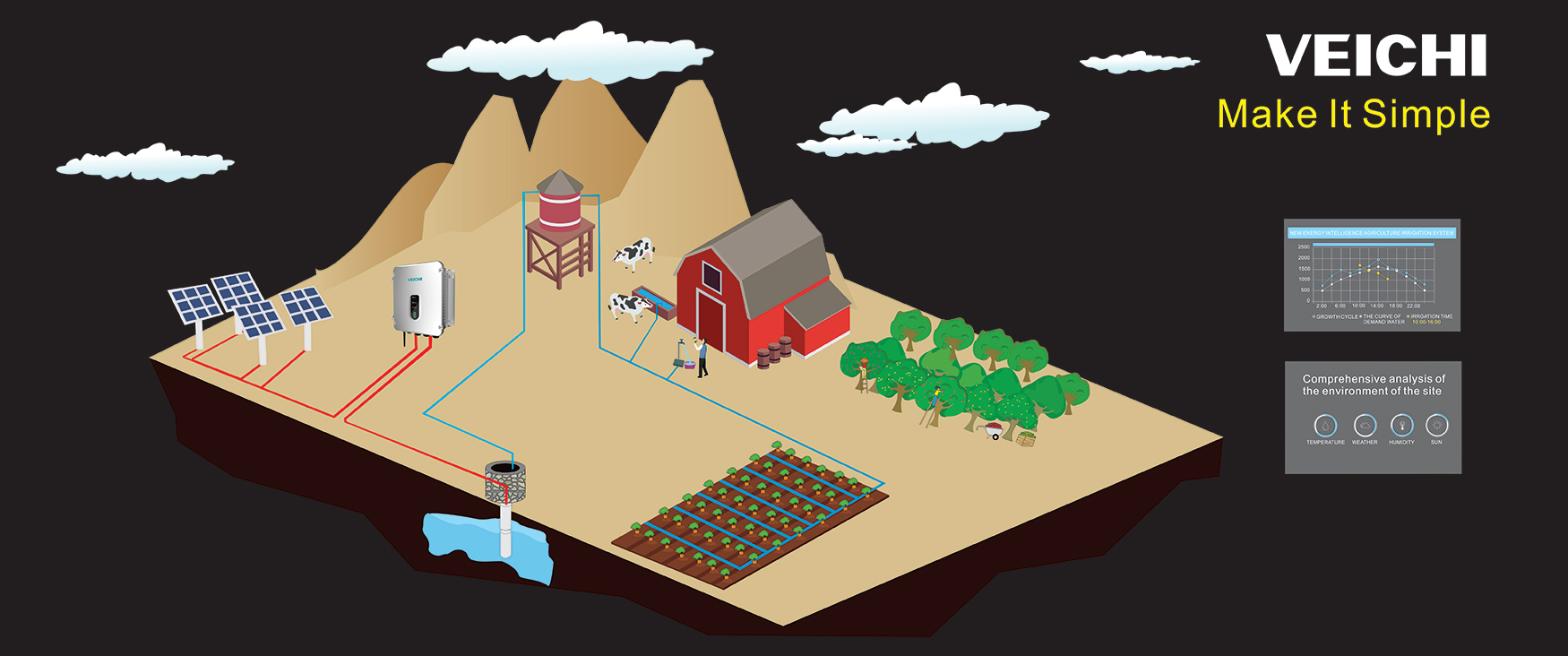

Photovoltaic water pump inverter: It is mainly used in farm irrigation, residential water, landscape fountain, swimming pool water supply, desert treatment, etc. Currently, there are SI20, SI22, SI23, SI30 and other products. The company's product features: cost-effective, high performance, automatic MPPT technology, full voltage range tracking, can drive a variety of different types of pumps (permanent magnet synchronous, asynchronous, single-phase motors, etc.), and it has a variety of protection functions (sleep, low frequency, dry, overcurrent, minimum power, etc.), with wireless transmission technology (GPRS, Bluetooth, WIFI), support intelligent IOT.

VEICHI SI20 solar pump inverter

VEICHI SI22 solar pump inverter

VEICHI SI23 solar pump inverter

VEICHI SI30 solar pump inverter

Wireless transmission module

The wireless transmission module is a module that realizes wireless transmission by using wireless technology, and it is widely used in various industrial fields.

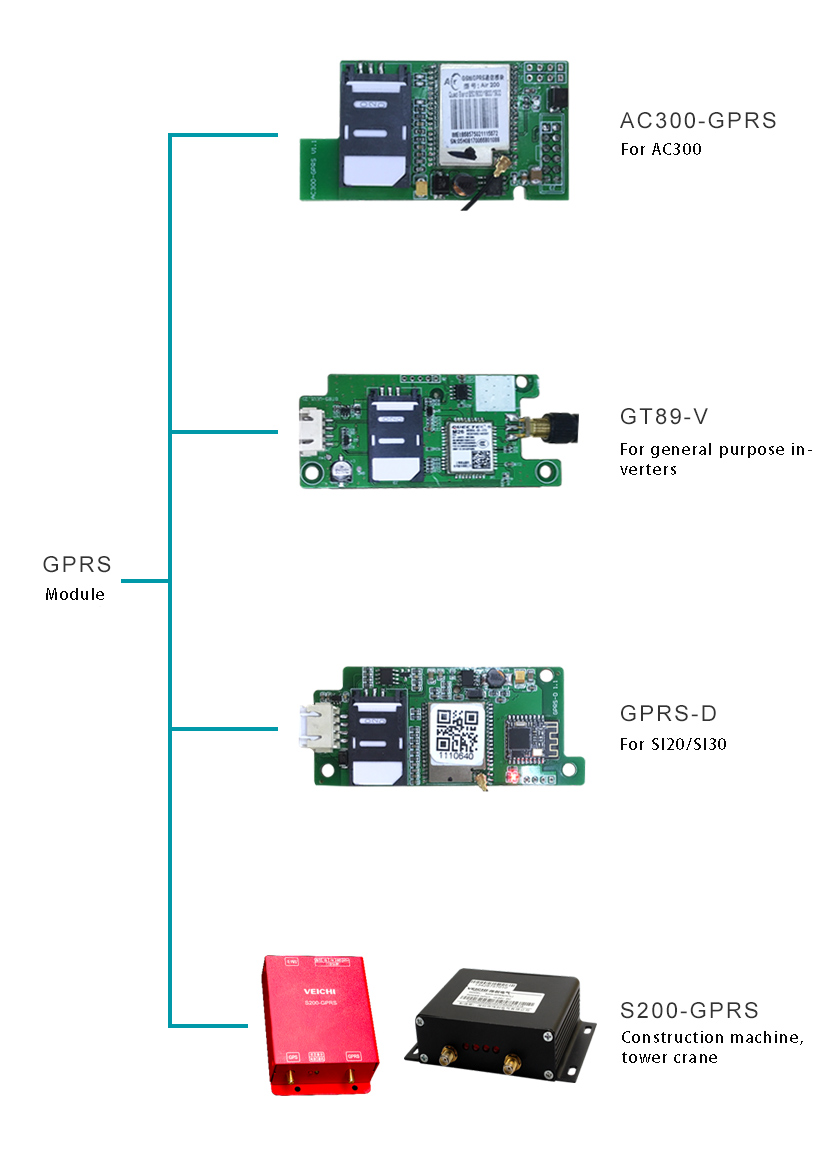

The wireless transmission module independently developed by VEICHI is mainly a GPRS data transmission module. It is based on mobile cellular technology, designed according to industry standards, integrated positioning and data processing in one module, small size, easy to install, suitable for various industrial sites. The company has launched a number of GPRS modules to meet the needs of different industries and create maximum value for customers. At present, the company has built-in and external GPRS modules, including S200-GPRS (B), GPRS-D, GT89-V, AC300-GPRS and other products. The company's GPRS data transmission module has the following main functions:

Auto registration: After the module is powered on, it will automatically request registration from the server.

Heartbeat detection: Sends module online status information to the server periodically.

SMS function: Use the SMS to monitor the internal parameters of the module.

Transparent transmission: Supports transparent transmission of data, making it easy for customers to customize non-standard protocols.

Remote lock machine: Remote lock machine (optional function) can be implemented in specific industries.

Real-time positioning: The module supports real-time upload of GPS and base station positioning to keep track of the location of the device.

Real-time positioning: The module supports real-time upload of GPS and base station positioning to keep track of the location of the device.Remote upgrade: The module supports remote upgrade, which can be upgraded by one button on the WEB platform.

Fault reporting: When the module or device fails, it reports to the platform in real time.

SIM card: Support SIM card access in different countries, set the internal APN to quickly switch to the local network.

SIM card

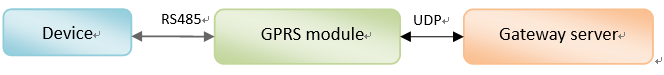

GPRS module communication process:

1. The GPRS module and the device are connected through the serial port RS485 to collect device data.

2. After processing, the GPRS packet data is sent to the GSM base station, and finally reaches the destination gateway server end.

3. The communication between the GPRS module and the gateway server adopts the UDP protocol of SOCKET.

4. The gateway server returns a response after receiving the instruction to ensure that the command is successful.

GPRS module communication proces

2.2 Data processing layer

The data processing layer includes three parts: gateway server, database and application server. It adopts key technologies such as distributed deployment and high concurrent processing to improve system performance and concurrency.

Key technologies:

1. Distributed deployment: Based on the processing power and performance bottleneck of a single physical server, the system cannot adopt the functional modular integration design, and the distributed file service is deployed to multiple different physical servers to improve the data processing and storage capabilities.

2. High concurrent processing: The system supports simultaneous concurrent communication between the batch terminal and the server. The use of multi-threading technology has improved data computing capabilities. In addition, the use of caching technology, shielding frequent and database access caused I/O load pressure, moving part of the data to the memory area, the internal data exchange speed is much higher than the speed of reading the disk, greatly improving the system performance.

Server role:

1. Gateway server: As a transfer station for data transmission, on the one hand, the data collected by the GPRS module is transmitted to the application server and stored data, and on the other hand, the client converts the command operated by the WEB or the mobile APP into a protocol and forwards it to the GPRS module. The gateway server is responsible for parsing logical processing such as data protocol packets, encryption and decryption, timeout processing, and filtering out error packets and illegal data packets. In order to improve security, the internal network and the external network are isolated, so that the external server cannot be directly accessed to ensure the security of the internal network server.

2. Database server: mainly used for storage and management of data, with fast and accurate query, data structure, data redundancy, data sharing, data independence and other advantages.

3. Application server: mainly used to analyze and process data, and provide various data interfaces for the platform display layer, such as management equipment, read and write parameters, view real-time data, view faults, and so on. All interfaces support JSON format for easy access and can also be extended to external interfaces for external system calls.

2.3 Platform display layer

The platform display layer is mainly the WEB IOT system and mobile client APP independently researched and developed by the company.

2.3.1 WEB IOT System

WEB IOT system adopts B/S architecture, users only need to read on the browser, it is suitable for computer, friendly interface, complete functions and simple operation.

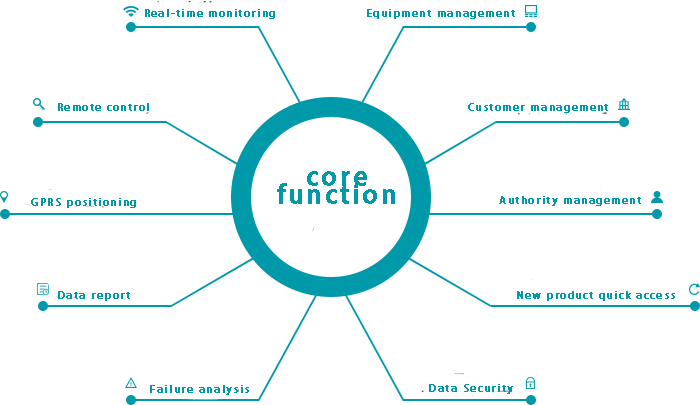

The core functions of the WEB side are as follows:

The core functions of the WEB side

Real-time monitoring: Real-time monitoring of equipment operating status and operating parameters, such as frequency, voltage, power, etc., while customizing industry-focused data to make work more convenient and faster.

Remote control: Remotely view and modify device parameters, such as run, stop, fault reset, support remote lock, unlock function, make the work smarter and more efficient.

GPS positioning: Real-time positioning tracking, intelligent display position.

Data report: The data report can be viewed and exported at any time to provide statistics on the running time of the device. It also supports graphical display.

Fault analysis: Real-time fault reporting, you can view the cause and solution of the fault, the fault record can be checked at any time, and the fault statistics function is provided, which is displayed in the form of graphs and lists.

Device management: Device type management, device parameter configuration, providing query and modification functions for device expiration, and easy management of devices.

Customer management: With layered management, the customer-level relationship is clear and easy to manage.

Rights management: Users assign and manage permissions for each role as needed, such as reading and writing parameters, device management, and viewing and positioning.

New product quick access: New products can quickly access the platform by simply configuring device parameters.

Data security: Multi-layer verification, data encryption and storage, safe and reliable.

2.3.2 Mobile client APP

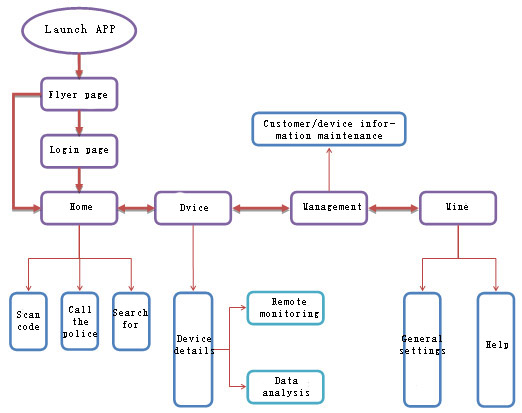

The mobile client APP adopts the C/S architecture, and the WEB IOT remote monitoring and management system is powerful, enabling customers to implement a series of complex management operations such as devices, customers, and accounts. The newly developed IOT APP not only inherits the original advantages of WEB, but also is easy to carry and simple to operate, greatly improving the user experience, allowing customers to manage and monitor devices anytime, anywhere, easily and conveniently. In short: WEB provides more powerful management functions, mobile provides better portability, and two screens allow customers to seamlessly manage devices.

Mobile client APP

The function flow of VEICHI IOT APP system is as follows:

The function flow of VEICHI IOT APP system

Industry Solutions

At present, The IOT remote monitoring and management system of VEICHI has been successfully applied to air compressors, photovoltaic pump inverters and general-purpose inverters, covering construction, textile, packaging, water pump, machine tools, chemicals, cables and other industries. , to achieve intelligent, professional control and management.

Air compressor: Before using the Internet of Things system, the maintenance and monitoring of the equipment adopts the method of manual inspection. Due to the harsh environment of the air compressor, this will increase the difficulty of the customer's work and cause problems such as untimely maintenance. After the system, through real-time monitoring and management, all parameters can be optimized remotely; the early warning system pushes the fault information to the maintenance personnel at the first time, and timely repairs and replaces, greatly improving the real-time maintenance of the equipment, saving labor costs and maintenance costs, and Support historical data, fault statistics, provide big data applications, and provide data support for customer product upgrades.

Air compressor

Photovoltaic Water Pump Inverter: Before using the IOT system, the data is collected manually, which consumes a lot of manpower and time. When the wearing parts are overtime and the maintenance is not timely, it will bring safety risks to the operation of the equipment. After using the Internet of Things system, 7*24 hours data is automatically collected and uploaded without interruption, and the state of the water pump controller is grasped in real time; based on the remote expert consultation function of the on-site environment, the accident handling capability is improved, and the cloud computing is based on the service life of the spare parts provided by the manufacturer. Automatically calculate the remaining usage time and remind you to replace it.

Photovoltaic Water Pump Inverter

General-purpose inverter: The textile chemical fiber and food packaging industry adopts the Internet of Things system, which can monitor equipment in real time, collect equipment parameters regularly, and intelligently alert. The SMS will notify the maintenance personnel of the fault information in real time.

General-purpose inverter

The software version of VEICHI IOT APP has been officially released online. The follow-up will be continuously optimized and updated, and the user experience will be continuously improved. Finally, attach the QR code of the special APP specially made by the artist and the company's products and service industry, and quickly scan the QR code download experience.

The software version of VEICHI IOT APP

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message