- Home

- R&D Innovation

- VEICHI AC800 Series Four-quadrant Inverter in the Experimental Platform of Motor Towing

With the rapid development of motor technology, CNC machine tools, industrial robots, and automated production equipment have begun to widely use high-efficiency motors as key components for motion control. Therefore, the performance requirements of the motor are getting higher and higher, especially its dynamic characteristics. At present, the traditional electromagnetic eddy current dynamometer and other technical equipment can no longer meet the testing requirements of current motor development.

After years of technical accumulation and in-depth market research and demand analysis, VEICHI has launched a new AC800 series inverter. With AFE energy feedback and common DC bus function, this feature is remarkable in the performance of the motor-to-drag platform. The AC800 series inverter is used to drive the AC asynchronous motor as a power test device to simulate the load. The electric energy generated by the AC motor working in the power generation state can be fed back to the grid from the AFE active front end, thereby reducing energy consumption. In addition, the direct current generated in the power generation state between the two motors can be consumed by the inverter of the other motor through a common DC bus, so as to achieve the maximum utilization of energy.

VEICHI AC800 Series Four-quadrant Inverter

In the near future, according to the actual application needs of users, for a certain equipment factory laboratory motor towing platform, VEICHI provides the AC800-M75-T4-1710 type four-quadrant frequency conversion cabinet solution.

The conventional test items of the motor-to-drag test platform mainly complete the following points:

1. Load characteristic test

2. T-N curve test

3. Durability test

4. No-load and locked-rotor test

The parameter information of the load motor is as follows:

| Name | Specification |

| Motor rated voltage | 380Vac |

| Motor rated power | 243kW |

| Motor rated speed | 12000rpm |

| Motor rated current | 392Arms |

| Motor overload current | 1000Arms, duration is 1min, working condition is 1 minute overload every 10 minutes |

| Working frequency | 0~800Hz |

System structure

AC800-M75-T4-1710 four-quadrant drive frequency

AC800-M75-T4-1710 four-quadrant drive frequency conversion cabinet is composed of control cabinet, incoming cabinet, rectifier cabinet and inverter cabinet.

Control cabinet: It mainly includes centralized control of the system, customer IO/DO port, panel control parameter display, etc.;

Incoming cabinet: adopts the method of the ground trough to enter, which is convenient for customers to connect;

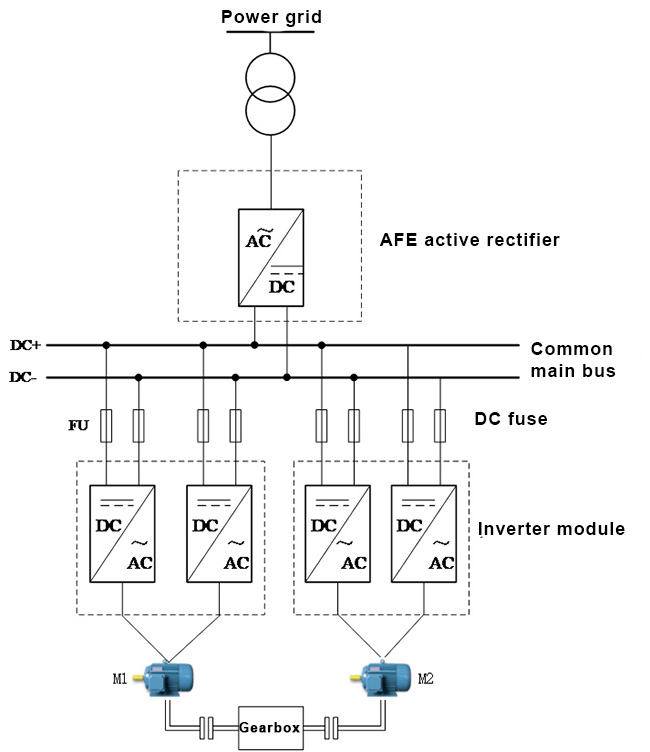

Rectifier cabinet: AFE active rectifier module, which can convert AC to DC on the grid side;

Inverter cabinet: Contains 4 inverter modules, which use double parallel connection to drive 2 motors.

System solution realization

Two sets of inverter units adopt the form of a common DC bus, respectively driving two AC asynchronous motors, one of which is the motor to be tested, and the other is used as a simulated load.

The towing test platform system

As shown in the figure, the towing test platform system uses a 380V power supply system, and the grid voltage is converted to DC power through the AFE active rectifier module and transmitted to the DC bus. Then it is distributed to 2 sets of inverter modules through a common DC bus, and each of the 2 sets of inverter modules drives 1 motor. The driving motor M1 and the loading motor M2 are connected through a coupling.

Through multiple combination modes such as speed mode and torque limit, it is possible to arbitrarily apply electric load or generator load to the motor under test, and the energy interacts through the public bus, which greatly saves power loss. At the same time, after starting the AFE active rectifier, the sudden deceleration and other excess power generation energy can be fed back to the grid.

System core advantage

1. Excellent control performance: The ARM+FPGA dual-chip control architecture can realize high-speed and high-precision loop control operations. Ensure the excellent dynamic response and control accuracy of the drive system. With VF, SVC, FVC control technology, it can drive asynchronous motors, permanent magnet synchronous motors, reluctance motors, and high-speed motors.

2. Convenient and quick debugging tools: the debugging upper computer that adapts to the working conditions is equipped with a convenient and quick multi-function LCD keyboard. It can realize simple and convenient debugging of handheld devices and support parameter copy and recovery.

3. Modular design and common DC bus scheme: filtering, rectification, inverter, and braking are all independent and standard modules. The common DC bus scheme is adopted to save energy requirements (5%-30%). Simultaneously supports multi-module parallel to achieve high-power output.

4. Abundant expansion interfaces to meet all customer needs: VCU supports a variety of expansion modules, including TTL, HTL, UVW, sine and cosine, resolver, and other encoder modules. Support Modbus, DP, PN, EtherCAT, and other Fieldbus modules, IO expansion modules, etc. Adapt according to customer usage.

5. Multiple fault handling and protection methods, safe and stable: The system has as many as 30 set protection methods and communication abnormal fault monitoring function. In addition, it is equipped with STO safety torque interrupt function as standard, which cuts off the power of the motor by blocking the IGBT drive pulse. Prevent the motor from starting accidentally and ensure the safety of personnel and equipment.

The AC800 series four-quadrant inverter of VEICHI adopts international leading technologies such as magnetic link closed-loop vector control and AFE feedback. With two modes of speed control and torque control, it provides a better choice for the test platform, which is proved by field application. AC800 series four-quadrant inverters, fully meet the application requirements of the test platform for motor performance testing!

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message