- Home

- Product Launches

- ID Engineer's Product Story · SI22 Birth Record

This article will tell you about the development process of SI22 from the perspective of an ID engineer.

Hello everyone, I am an ID engineer of VEICHI, I am coming again.

The product to be introduced to you this time is an integrated special machine developed by VEICHI: SI22 solar pump inverter.

Process

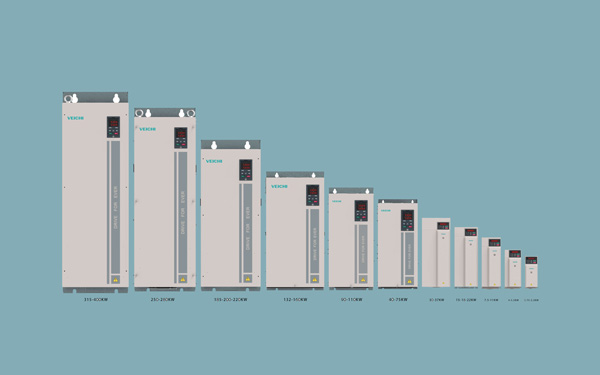

SI22 is a new cost-effective, economical, compact and innovative PV pump inverter. Its superiority is reflected in: Intelligent IOT,optional IOT module, which integrates online, offline and WIFI functions; MPPT Technology: Automatic MPPT technology, full voltage range tracking; drive a variety of pumps: powerful, it can drive both conventional pumps and PMSMs.

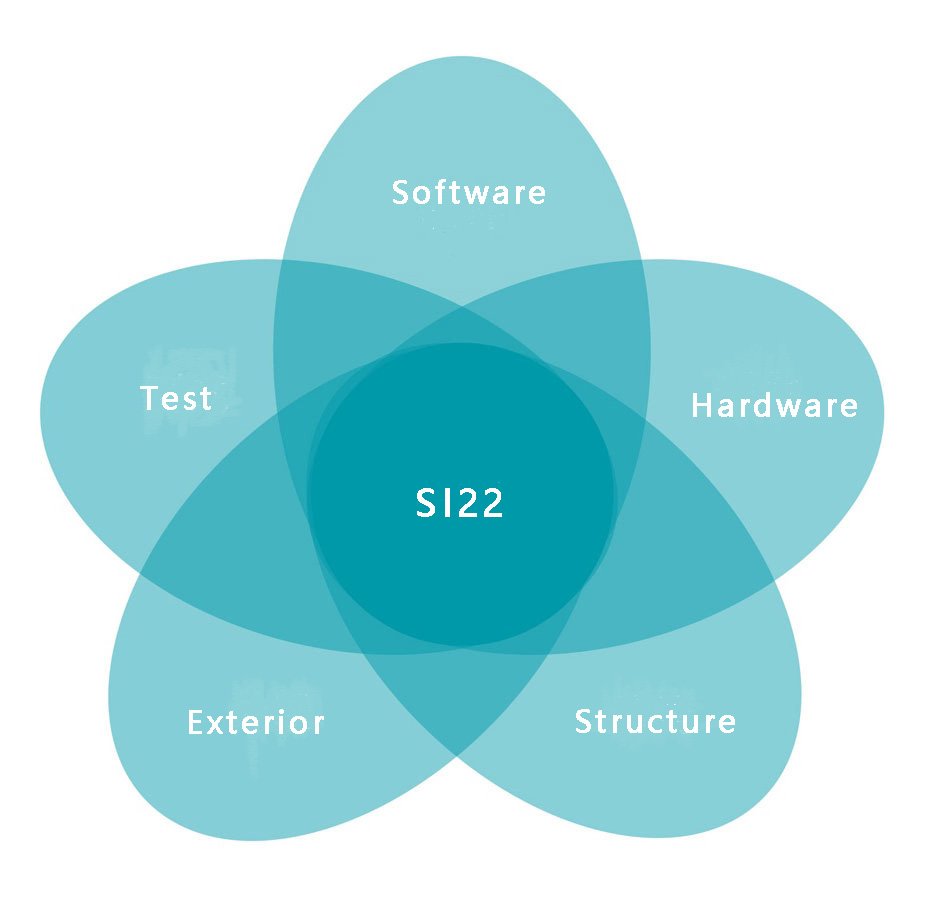

Relying on the PLM R&D management system, every detail of hardware, software, structure, appearance and testing in the SI22 development process has been repeatedly tested and simulated.

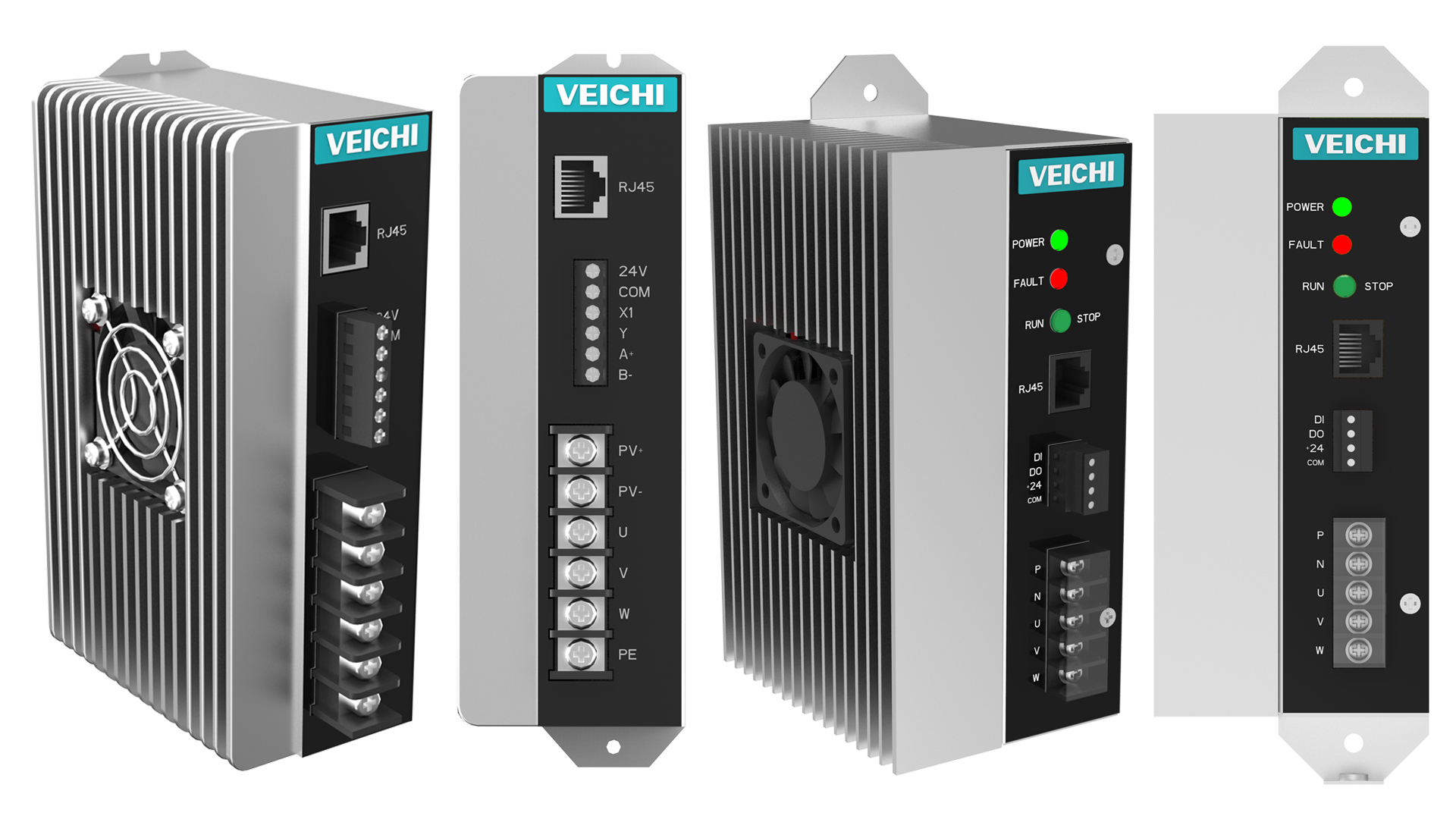

SI22 solar pump inverter

The core requirements of this product are: slim and compact, cost-effective and high reliability.

At the same time, as a series of products integrated with solar pumps, it is necessary to maintain the family and continuity of the PV pump special machine series.

Conceptual stage

Conceptual stage

In the prototype stage of the product concept, the concept prototype is first established according to the basic needs. ID engineers use the conceptual model as a medium to communicate with other members of the project team to brainstorm and explore the possibilities and feasibility of various options.

The model effect of the concept stage is open and changeable. At this time, the design thinking can diverge in different directions. This is the most free and flexible stage of the design idea, and it’s full of various possibilities.

Overview stage

Overview stag

The work to be done in the outline design phase is based on the results of the concept phase, it’s work for balancing the needs of software, hardware, structure, and market in all aspects, and gradually narrowing the scope of the trial.

The way of the program is expressed is also transformed from a rough conceptual rendering to a delicate simulation rendering, which is more intuitive and clear for the details of the product.

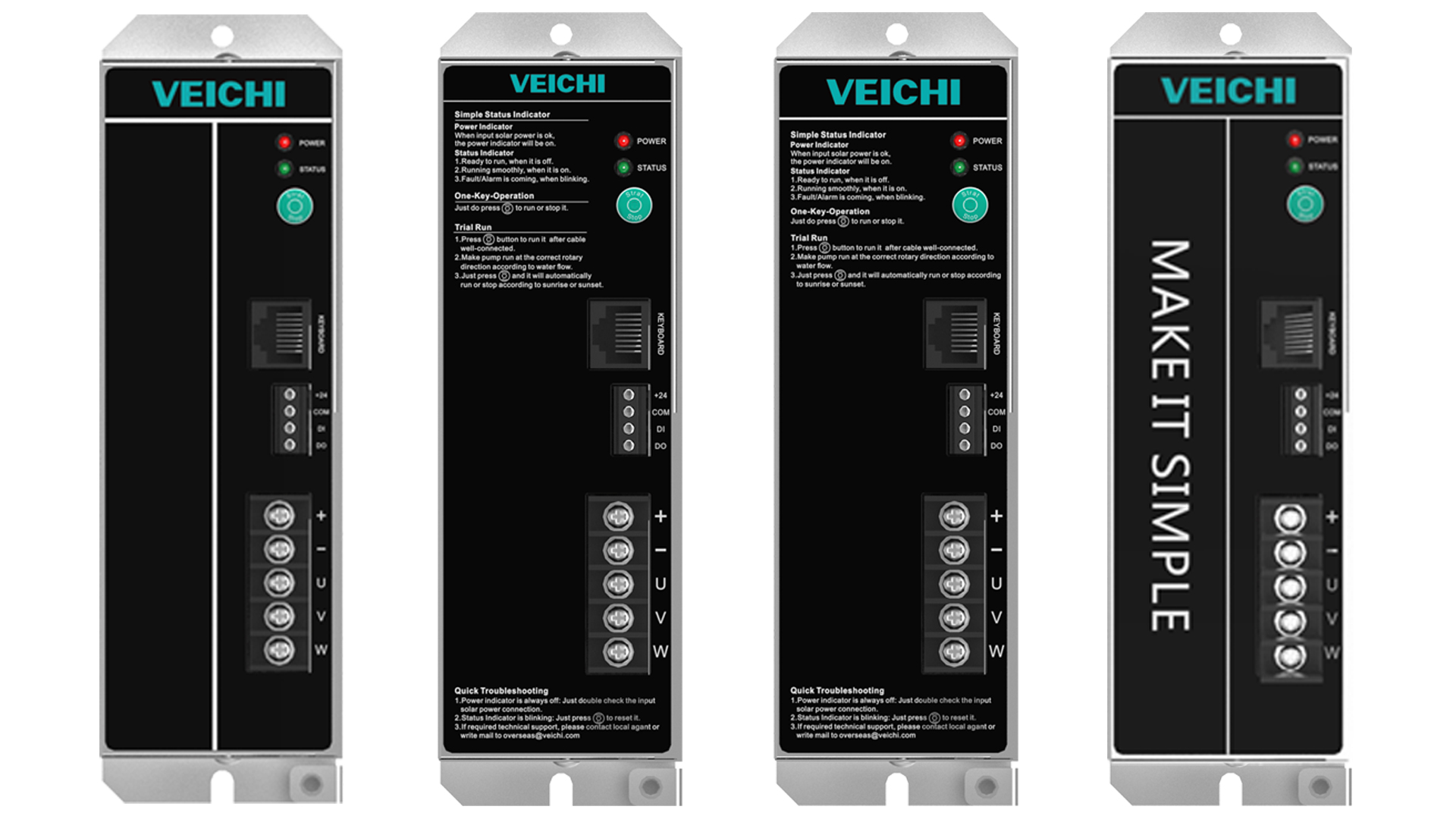

At the end of the summary phase, the prototype of the SI22 has been basically formed: the CMF (color, material, facial treatment process) of the product has been roughly determined; at the same time, the main appearance elements of the product such as buttons, indicators, terminals, explanatory text, etc. It has been basically determined, and the details of the product can be adjusted later.

Detail design

Detail design

In the detail design phase, each change has been carefully considered and revised.

For the contents of the SI22 mask, the project leaders Mr. Wang and Mr. Xing repeatedly rethought and constantly considered the market demand and the user's use environment. After many revisions, the final mask content was finally finalized.

During this period, Mr. Xing repeatedly went to Dubai, India and other countries for market research. In addition to the busy work schedule abroad, he also has to overcome the time difference and continuously communicate with the domestic project team about the project content and follow up the progress of the project.

Mr. Xing, Mr. Wang, and every member of the project team, everyone is working hard on the SI22 project. The ultimate goal is to produce a high-scoring answer to the market and produce a product that is satisfactory to customers.

Sample follow-up

Sample follow-up

After finalizing the product details, it is necessary to make a hand-made and proofing product.

When you get the physical products, I can have a more intuitive understanding of the design results, I may find some 3D models and renderings cannot show the problems. By correcting and adjusting these problems, we finally get products that can be trial-produced and mass-produced.

The above process is from the perspective of ID engineers describes the general process of the birth of SI22. In the process of product development, all departments must continuously communicate, discuss, and modify each other under the leadership of the project leader. In such a reciprocating cycle, the balance point and the optimal solution are finally found among the dominant factors, and resulting in a final product design.

In the future, VEICHI will continue to drive an endless R&D attitude: strive for excellence, strive to make products better and give customers a better experience.

A photo of the SI22 solar pump inverter and the “Cousin" SI30 solar pump inverter are attached at the end of the article!

SI22&SI30 solar pump inverter

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message