- Home

- Product Launches

- ID Engineer's product story · AC10 birth record

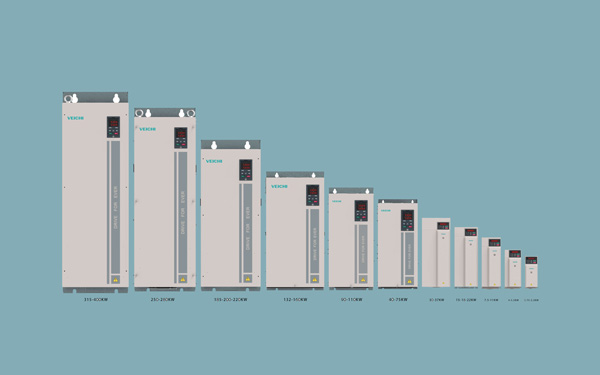

AC10 series inverter is developed for the market demand of miniaturization, high reliability and high cost performance. It has many advantages such as small size, low temperature rise, superior performance, convenient installation and beautiful appearance.

Relying on the PLM R&D management system, in the development process of AC10, all departments work closely together, and the research and development process is three-dimensional, systematic and traceable, ensuring the rigor and science of the product.

Next, the author will talk about the development of AC10 from the perspective of an ID engineer.

Hello everyone, I am an ID engineer of VEICHI.

When the product is compared to human beings, the software is the soul, the hardware is the organ, the structure is the bone, and the appearance is the skin.

Then everyone can understand my work simply and rudely as: skin design engineer. (Although the depth of industrial design is much more than that)

All say that a good skin bag is all alike, and an interesting soul is one in a thousand. My job is to create a beautiful and unique skin for the interesting soul of VEICHI products.

In late March 2018, the project leader of Tang, he found me and talked about the company's intention to develop a brand new product: AC10.

I understood the core requirements of this product are: miniaturization, cost-effective, high reliability.

Next, we need to clarify the core requirements of the product and the market positioning. After a lot of market research and analysis and discussion with the project team members, we have unanimously determined that the ID requirements of the AC10 product are: slim, compact, novel, beautiful and easy to use.

While fulfilling the above requirements, in the process of design, I must ensure the brand, family and continuity of new products, but also consider the cost and other factors.

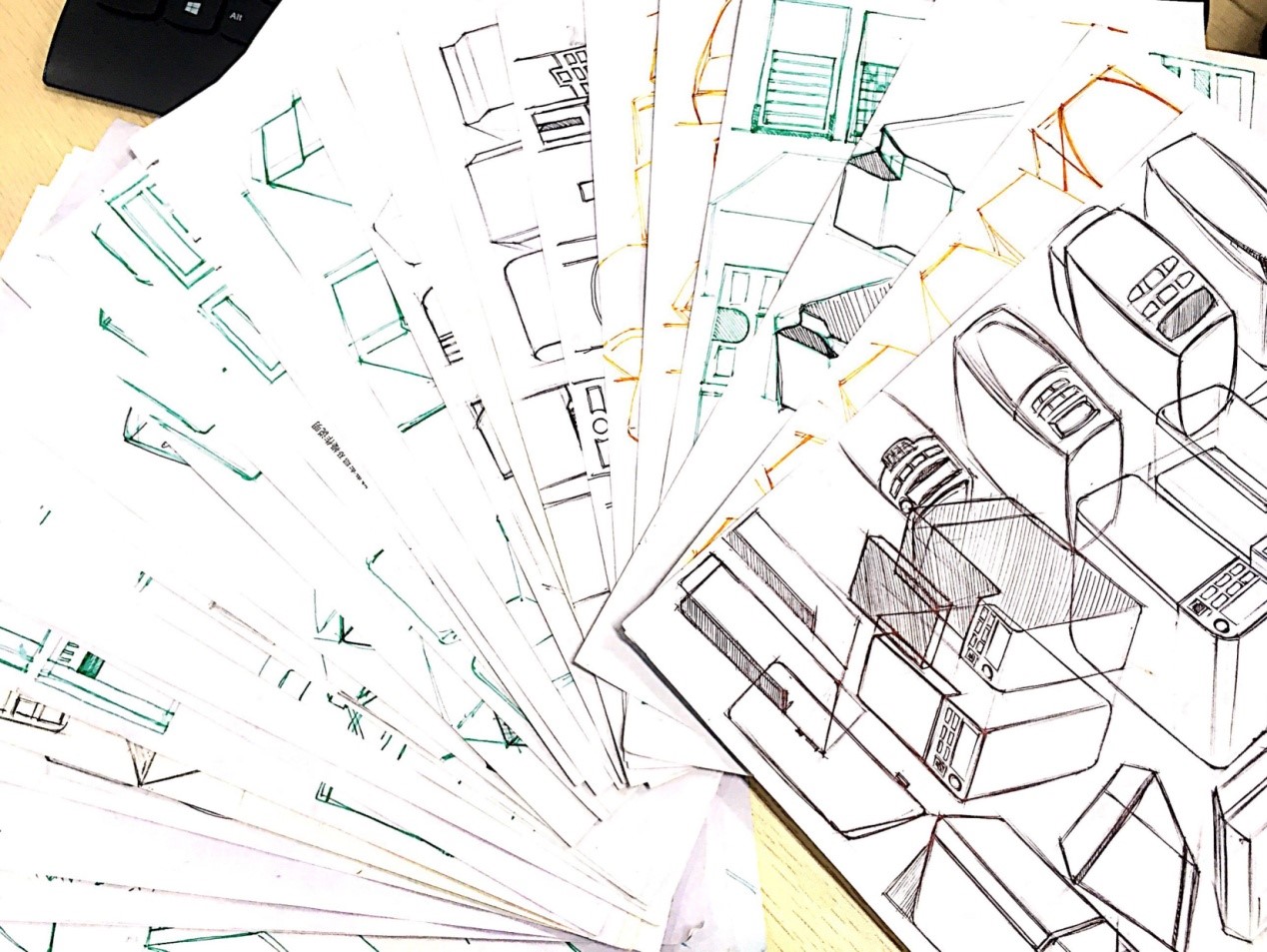

In the conceptual phase of design, I have drawn a large number of sketches, some of which have a higher degree of completion and some are just outlines.

In the conceptual phase of design

At this stage, I need to use this way to divergent thinking, constantly explore the possibilities of the product, and constantly communicate with other members of the project team to explore the feasibility of various programs.

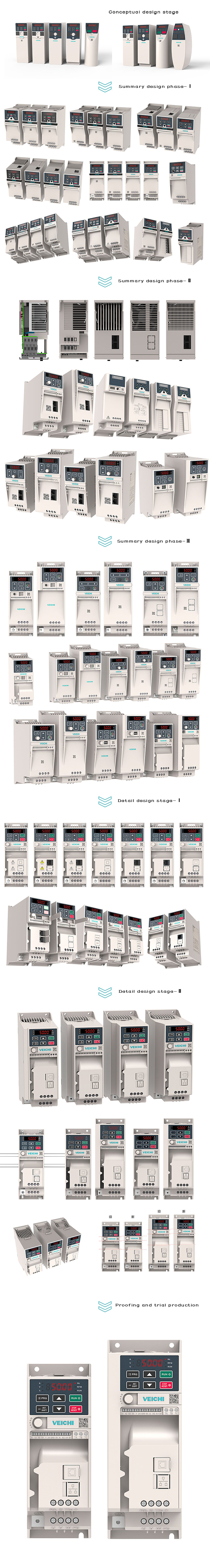

In the summary phase of the design, it based on the results at the conceptual stage, I need to balance the needs of all aspects of software, hardware, and structure, and gradually narrow the scope of the experiment. The way the program is expressed is also converted from a concept sketch to a model rendering, which is more intuitive and clear for the product display.

At the end of the summary phase, the prototype of AC10 has been basically formed: the CMF (color, material, surface treatment process) of the product has been roughly determined, at the same time, the main appearance elements of the product such as display screen, buttons, terminals, etc. have been basically clear. A more delicate design can be developed to adjust the details of the product.

By the time of the detail design phase, each change has become more targeted, so each design change is more cautious and meaningful.

The summary phase

After finalizing the product details, it is necessary to make and proof the product. After getting the real thing, you can have a more intuitive understanding of the design results. In the process, you may find some 3D models and renderings that cannot be displayed. Through the continuous correction and adjustment of the design plan, the products that can be trial-produced and mass-produced are finally obtained.

The above process only describes the general process of the birth of AC10 from the perspective of ID engineers. In the actual work process, industrial design is closely linked with other design work.

When I am a student, there are words that I have always remembered: industrial design is the perfect combination of technology and art.

VEICHI AC10

In the process of product development, all departments must continuously communicate, discuss, and modify each other under the leadership of the project leader. In such a reciprocating cycle, the balance point and the optimal solution are finally found among the dominant factors, resulting in a final product design.

In the future, VEICHI will continue to drive an endless R&D attitude and strive for excellence to make products better; we will give customers a better experience.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message