- Home

- Product Launches

- VEICHI SD700 Servo Drive Will Be Released Soon

In recent years, the general servo industry is of great development that there is a huge potential market both at home and abroad. However, when it refers to the servo products such as servo driver and servo motor produced by China manufacturers, most of the people will be occurred by a bad impression such as: unstable performance, poor accuracy, slow response, and difficulty in setting parameters… Due to these reasons, the user experience of servo products what are made in China is dissatisfactory.

In case like this, VEICHI develops the new SD700 Servo System with brand-new software, hardware, control algorithm, design and platform, which will change people's impression and experience upon the general servo system made in China.

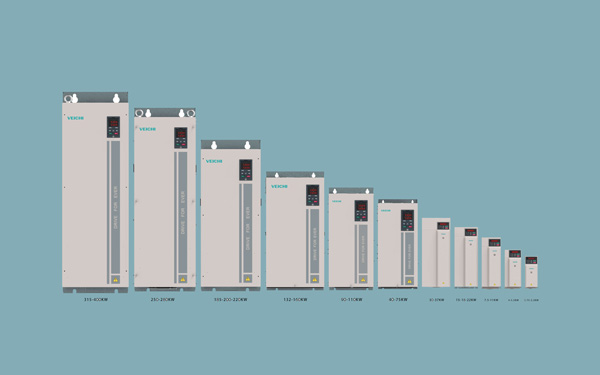

SD700 servo drive

Key Features of VEICHI SD700 Servo Products

1. Install and Play, Without Debugging

Modern robust control is a controller design method that focuses on the reliability of control algorithms. The goad of the design is to find the minimum requirements that must be met in order to ensure the safety requirements of the control system in the actual environment. Once the controller is designed, its parameters can not be changed and the control can be guaranteed. At present, VEICHI is the first one who owns this core technology in China.

VEICHI SD700 has been activated "robust control" mode as factory default that it can achieve smooth and stable running without parameter setting as long as the load inertia is less than 30 times(even if the load changes during the movement process).

Without-debugging servo drive

Install-and-play servo drive

2. Intelligent Setting

VEICHI SD700 has been developed with self-learning function and intelligent settings that it can complete inertia identification, PID gain, feedforward gain, friction compensation, vibration suppression, complex loop parameters adjustment and other settings without manual operation. What's more, the position setting time can be up to 10ms when you adopt this mode for parameter adjustment.

We have realized the simplification and intelligence of the debugging process for servo products. It can easily meet the performance requirements of 80% users.

3. Maximally Match 24bit Absolute Value Encoder

VEICHI SD700 servo system features high positioning accuracy and high stability at low speed what reaches the top level in the industry.

4. Fast Computing Speed and High-Speed Bandwidth

Its current loop operation cycle is 400ns, speed loop response frequency is up to 3KHz, besides, the speed loop and position loop refresh cycle is 125μs.

5. Rich Vibration Suppression Function

SD700 servo system can effectively suppress 1 ~ 100Hz low-frequency vibration (shaking). The cantilever structure is very easy to cause "swing arm effect", resulting in the end of jitter, this can be effectively avoided by manual / automatic set to vibration filter. Its vibration suppression function including low frequency resonance suppression, intermediate frequency vibration suppression and notch filter can be automatically and fully set.

6. Optimized Appearance Design

Except the rich functions, SD700 also has developed with brand-new design: width reduced by 20% comparing the previous machines.

7. Other Functions

a. Power section: 50W – 11KW

b. Offline inertia identification function

c. Speed loop observer

d. Standard dynamic braking function

e. Powerful host computer function

f. Rich motor type, including low inertia high speed series, high inertia high speed series, high inertia low speed series.

g. The maximum speed of the motor is up to 6000RPM; the maximum output of driver and motor is up to 350%.

Side-view of SD700

Early Target Market of SD700 Products

1. Glass Engraving Machine

Glass carving machine is a kind of CNC machine tools mainly used for processing touch screen glass of consumer electronic products such as mobile phones, tablet PC and etc. The glass engraving machine requires good track follow ability, VEICHI SD700 can fully meet the high requires in position following.

Glass Engraving Machine

2. Die Cutting Machine

Die cutting machine is mainly used for die-cutting, indentation, bronzing of some materials such as non-metallic materials, stickers, EVA, double-sided adhesive, electronics, mobile phone pads and etc. It is important equipment for packaging processing. The major requirements of die-cutting machine are fast response and big-inertia motor.

Die Cutting Machine

3. Slant bed Lathe

Slant bed CNC lathe is a high precision, high efficiency automatic lathe. Equipped with multi-station turret or power turret, the machine has a wide range of processing performance, capable of processing linear cylindrical, oblique cylinder, arc and a variety of threads, grooves, worms and other complex parts. It majorly requires smooth speed during the turning process, which ensures the gloss.

Slant bed Lathe

4. AOI Testing Equipment

The AOI detection equipments automatically scan PCBA products and capture images through the high-definition camera, then compare the test point and the qualified parameters in database. After image processing, check the target product defects, and mark out the defects through the display or automatic signs, so the maintenance personnel and SMT engineers can improve the process accordingly. The major requirements are point-to-point fast positioning, fast response requirements to servo.

AOI Testing Equipment

As reported, the VEICHI A-type SD700 servo drive will be announced to market in June, 2017. Let's look forward to it!

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message