- Home

- VEICHI News

- VEICHI Intelligent Solution for Battery Swap Station Helps Heavy Trucks Develop Vigorously

With the continuous promotion of the "carbon peaking and carbon neutrality" strategy, heavy trucks with changeable batteries are now facing an important development node, and battery swap stations for them are in urgent need now. With in-depth insight into the new energy heavy truck battery swapping needs, combined with technical advantages in the fields of power electronics and industrial control, VEICHI has now proposed an intelligent unmanned solution to provide fast, efficient and safe charging and swapping services, adding power to the popularization and sustainable development of new energy heavy trucks.

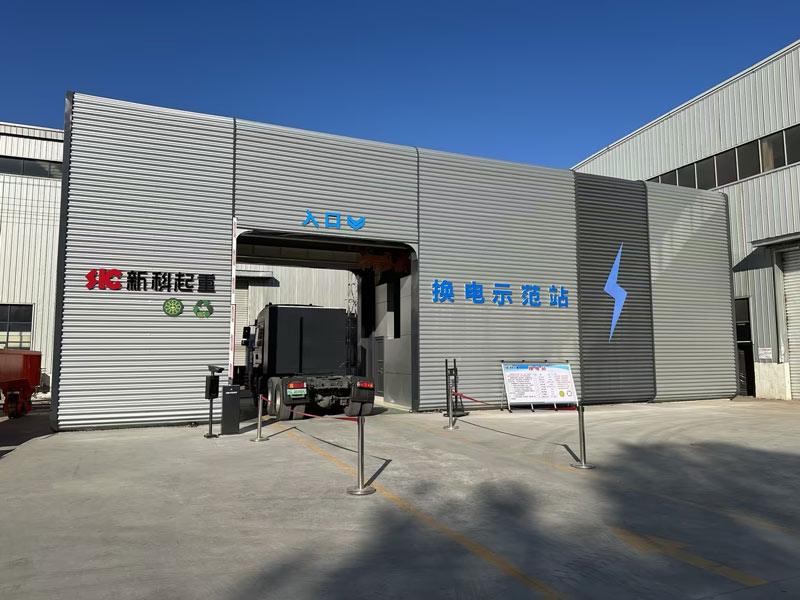

Intelligent Trucks Battery Swap Station

VEICHI Solution

Green Impetus for Heavy Truck Transportation

According to the characteristics of battery swap stations for heavy trucks, VEICHI proposed an intelligent and unmanned hoisting battery station solution featuring mature technologies, high reliability, lower cost, smaller land occupation and faster swapping efficiency. The whole scheme adopts 7 + 1 structure, which is composed of intelligent system, modular charging bin, automatic power swapping system, vehicle management system, environmental safety facilities etc. The whole process is fully automatic and takes about 3-4min and fully meets the daily operation requirements.

Intelligent and Unmanned Hoisting Battery Station Solution

Solution Composition

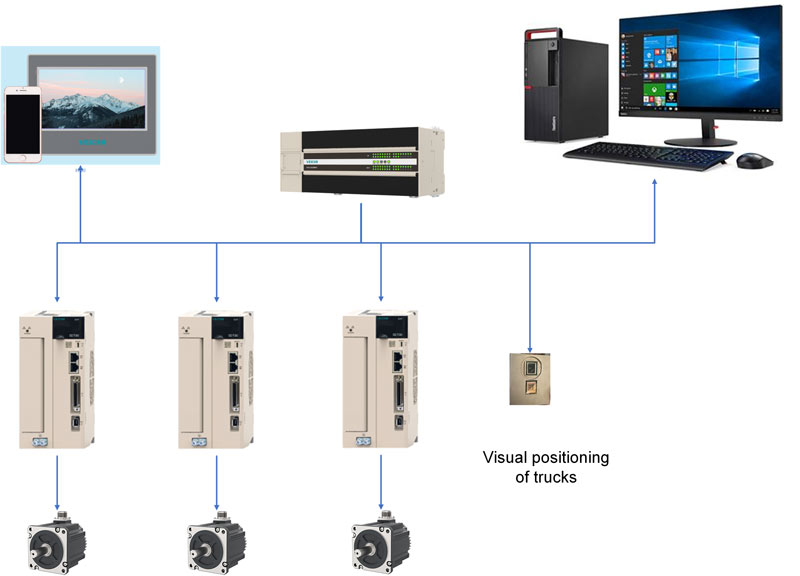

Intelligent System

It includes data monitoring system, remote control system and battery management system to monitor and manage the whole battery station and each component.

Modular Charging Bin

This is used for battery charging and storage, including battery changer and battery storage devices.

Automatic Battery Swapping System

This means truss robots, including various detection and positioning equipment used to quickly replace the batteries of heavy trucks.

Vehicle Management System

This is used to manage the information of vehicles and drivers entering and leaving the heavy truck battery station to keep traffic orderly and safe.

Safety Facilities

This includes fire prevention, explosion prevention, waterproof facilities to ensure the operation environment of the battery station.

Solution Topology

Solution Topology

Solution Advantages

Fully automated, precise and intelligent operation

With intelligent technology, the full-automatic process from vehicle entry and exit to battery replacement is realized, which greatly improves working efficiency.

Unmanned operation, maximized safety and cost

Since there is no need for manual work, staff operation and management is reduced, so is the operating cost, and the safety risks caused by manual operation are also reduced to ensure the safety of the battery swapping process.

Uninterrupted, efficient and all-round service

Uninterrupted work for 24 hours per day continuously provides fast and efficient battery replacement service for vehicles.

Online monitoring, intelligent battery management

Intelligent system can accurately monitor battery status to realize optimal battery charging and scheduling, prolong battery life and improve service efficiency.

Simple process, improved user experience

Automated process provides more convenient and faster service, and better experience for users.

Visual management, real-time data analysis

The intelligent system of unmanned battery station can collect a large amount of data and analyze them to support for operation optimization in each aspect greatly.

Key Technologies

Optimal path algorithm

Planning the most efficient path for battery pickup based on interference and distance to reduce time and energy.

Constant power algorithm

Operating speed regulation to maximize the power output with load changes, and thus improve the operating efficiency.

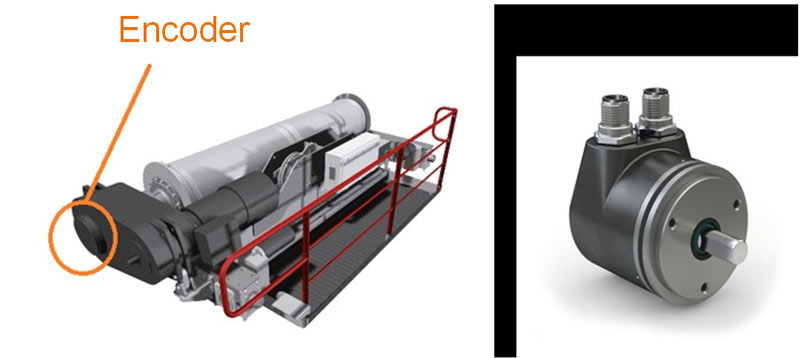

Precise positioning

Absolute value encoders and laser positioning technologies ensuring three-dimensional coordinates collection for accuracy and safety during the power swapping.

Encoder

Optimal battery scheduling algorithm

Management and control of the battery charging/discharging according to the battery status and vehicle demand to determine maximize the service life and use efficiency of the battery.

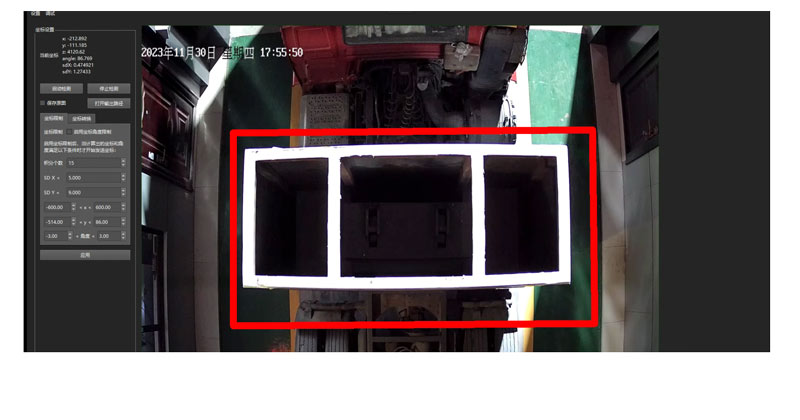

Visual positioning algorithm

Image information from a 3D camera processed and analyzed by computer vision techniques for the exact position of the truck motor with positioning and tracking.

Visual Positioning Algorithm

Vehicle information recognition

Vision technology and image processing algorithms automatically activating the appropriate services to recognize vehicles and extract key information including location, license plate features, and license plate recognition to improve operation efficiency.

Data processing

Database building and customized data available by collecting, organizing and analyzing all of the system data.

Data processing

VEICHI focuses on the actual experience of users and the applicability of the solutions, and improves usability, precision, reliability and safety comprehensively to better support for the intelligent battery swapping of heavy trucks. In the future, VEICHI will continue to explore the demands from various industries, and make more accessible and cutting-edge solutions through technological innovation and collaboration among industries, contributing to the industry's green and sustainable development.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message