Application of AC310 Series AC Drive VFD in Paper Towel Slitting Machine

Introduction

- Introduction

- Related Products

- Related Solutions

- Other Related Cases

- Additional Information

- Contact us

Overview

With the advancement of urbanization and the improvement of per capita living standards, the consumption of sanitary paper continues to increase, and the domestic household paper industry has been growing. According to statistics, there are 2.181 million sanitary products related companies in China, of which Guangdong has the largest number, reaching 394,000.

Sanitary paper towels have always been a necessity in life. With the upgrading of consumption and technological progress, the overall quality of household paper continues to improve, and the consumer demand for paper towels is becoming more refined and specialized. The production of sanitary paper packaging machinery has greatly improved the efficiency of manufacturing and packaging. VEICHI frequency inverters are used in the control system of sanitary paper equipment, which can adapt to diversified processing and packaging requirements, significantly improve packaging efficiency and quality, and reduce corporate operating costs.

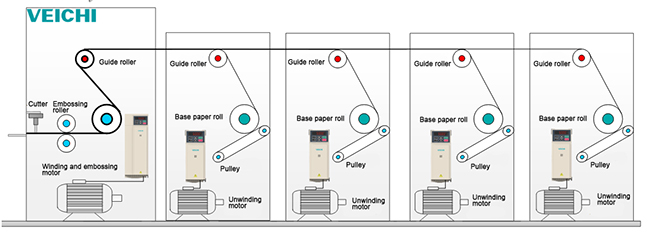

Figure 1-1 Schematic diagram of equipment system

System introduction and process requirements

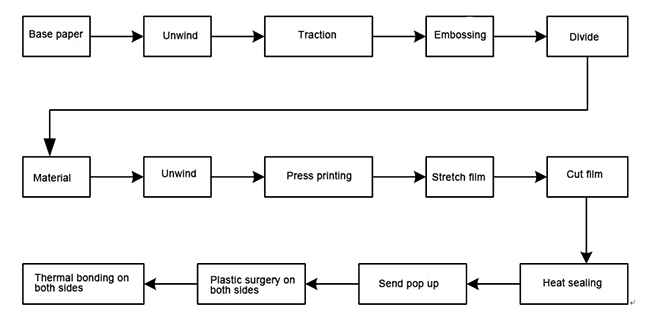

Automatic paper-pumping production equipment is mainly used for cutting, bagging, and packaging the base paper of soft-pumped tissues of various specifications, instead of traditional manual production of packaging, and placing the base paper products on the machine feeding device. That is, a series of processes from the base paper to the finished product are automatically completed. The process flow is shown in Figure 2-1.

Process requirements: The equipment has higher requirements for the overall stability and accuracy of the control system during high-speed operation. Due to the flexible characteristics of paper towels, unwinding, traction, cutting, film pulling, and intermediate delivery are extremely error-prone links in the packaging process. It is no small test to ensure the packaging effect, avoid inaccurate sealing and cutting, run off the film, and run out of empty bags.

Figure 2-1 Process flow

Electrical schematic diagram

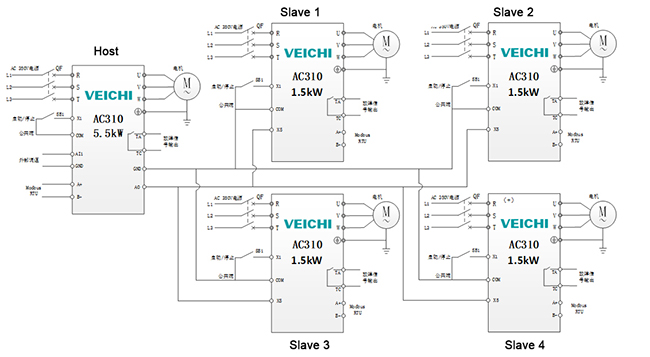

(1) The HMI+PLC+ frequency inverter scheme is adopted on-site, the following is mainly the schematic diagram of frequency inverter wiring.

(2) The inverter adopts one master and four slaves for configuration. The frequency of the host inverter is externally given by PLC and HMI, and the frequency of the slave is given by the pulse output of the host, and the master and slave are proportionally synchronized.

(3) The status of all the master and slave inverters are fed back to the PLC through RS485-RTU communication.

Figure 3-1 Schematic diagram of inverter electrical wiring

Advantages

Large starting torque at low frequency, 150% of rated torque at 0.5Hz.

High-speed stabilization accuracy, which can effectively prevent the occurrence of paper breaks.

The proportions are synchronized and consistent, and the four-layer paper is not easy to run off.

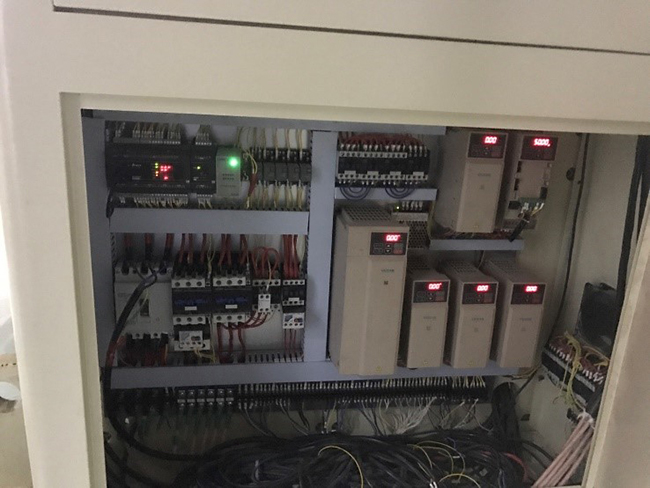

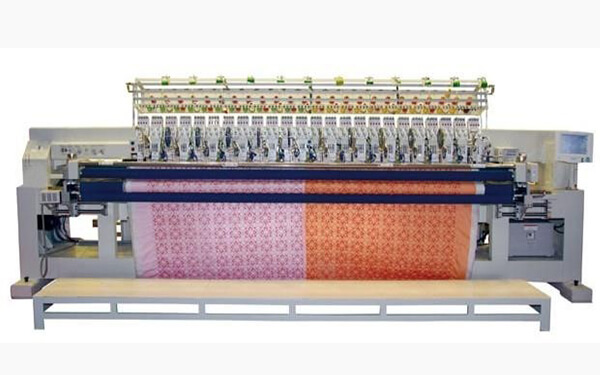

Field application diagram

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message