Water Jet Loom Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Water Jet Loom Solution

In the textile water jet loom equipment, there are many kinds of fabrics, and the conditions such as speed, opening and weft insertion are different for different varieties. Reasonably changing the mechanical transmission to the motor transmission and adding the intelligent adjustment function of the loom can greatly improve the automation degree of the machine and promote it to be widely used in the new textile industry.

VEICHI integrated water jet loom control system is an overall solution that integrates loom controller, pattern board, electronic take-up and let-off, and spindle drive. The core synchronous motor vector control technology of VEICHI makes the system energy saving rate as high as about 20%, which greatly improves the digital and intelligent level of water jet looms.

Features and Benefits

Water Jet Loom Solution Features & Benefits

VEICHI water jet loom integrated electronic control system, integrated design, high protection level, frequency conversion direct drive system.

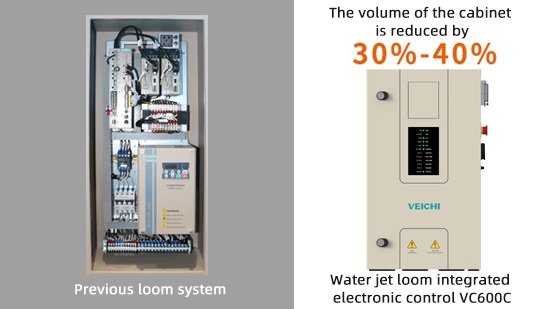

Integrated Design with Box

Compared with the traditional electronic control system, the VC600C all-in-one machine integrates the original independent controller, frequency converter, and let-off winding servo driver. The space utilization rate is greatly increased, and the volume of the box is reduced by 30%-40%.

High Protection Level

Closed box design, high protection level, waterproof, dustproof and oil-proof, effectively isolating the influence of water vapor and oil pollution on the equipment operation and service life on the textile site. The fanless design solves the problems of easy damage and short service life of traditional textile control cabinet fans. Reduce maintenance costs, and the enclosure protection level reaches IP54.

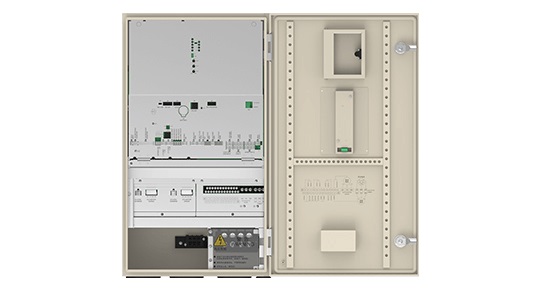

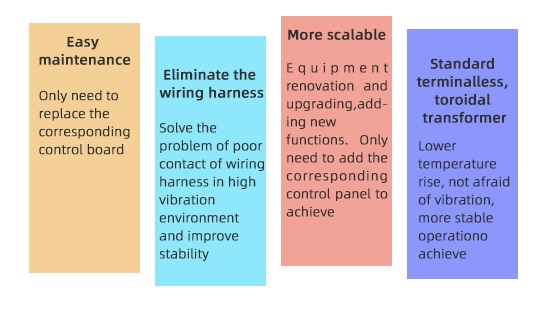

Plug-in Wiring Design

90% of the interface of the whole machine adopts plug-in design, which has a simple appearance and is easy to maintain. Save 10%-20% in installation man-hours.

Modular Design

VC600C all-in-one machine relies on the rich product line of VEICHI, and adopts advanced modular design concept in the cabinet, and the layout is more reasonable. It has the advantages of convenient maintenance and strong scalability.

Inverter Direct Drive System

Standard variable frequency drive, which can be compatible to drive asynchronous motors and direct drive motors at the same time. It has the functions of slow jog, super start and free speed change. Optional direct drive motor, using an integrated glue filling process, the protection level is up to IP68, which is perfectly suitable for the high temperature and high humidity environment of textile factories.

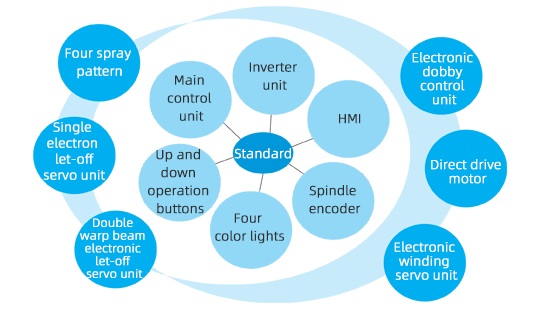

Rich Configuration

Standard configuration: main control unit, frequency conversion unit, HMI, spindle encoder, four-color lights, up and down operation buttons;

Optional: four-jet pattern board, single electronic let-off servo unit, double-beam electronic let-off servo unit, electronic winding servo unit, direct drive motor, electronic dobby control unit.

Doing Business

We listen to learn about you and your customers, what you are trying to accomplish and the project goals. We bring you technical and application expertise along with an extensive portfolio of hardware and software solutions that can help you give your customers the foundation to build a plant for the future.

Your customers demand solutions that increase agility, optimize productivity, and position them for growth. Helping your customers accomplish their objectives requires the use of new and innovative technologies, from highly scalable hardware and software solutions that seamlessly integrate with each other to the tools for monitoring, reporting and analyzing operations.

Our focus means that you are assured the solution for your customer goals.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message