- Home > Product > Industry-specific Drive > Textile > VC600C Water Jet Weaving Electrical Control System

VC600C Water Jet Weaving Electrical Control System

- The five-in-one integrated system supports electronic multi-arm jacquard control, built-in winding and take-up servo and super-start inverter

- Built-in super-start frequency conversion, can realize slow jog and variable speed weaving, compensate the first latitude torque and prevent yarn slack

- Advanced parking gear optimization, built-in textile expert database, one-button weft weaving navigation

- Digital weft detection technology, reducing air conditioning and leakage, and improving weaving efficiency

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

VC600C Series Integrated Electrical Control for Water Jet Loom Overview

VEICHI weaving direct-drive spindle system solution, equipped with VEICHI "core" direct-drive electric spindle system, came into being for the weaving industry to enter the intelligent equipment. The configuration includes water jet weaving "navigator", main control system + let-off and take-up system + direct-drive electric spindle system. External equipment can support weft feeder control, dobby jacquard control, to meet customer customization needs. Supports double pumps and four jets, variable speed, and weft density weaving. The upper and lower warp beams, the left and right warp beams, and the outer winding control of the machine.

Features

1. Waterproof and oilproof: Easy installation,high protection grade,high visibility,fanless design to prevent steam and oil vapor.

2. Reliable connection: Internal and external plug-in wire connections make the product with more extensibility and easy to maintain.

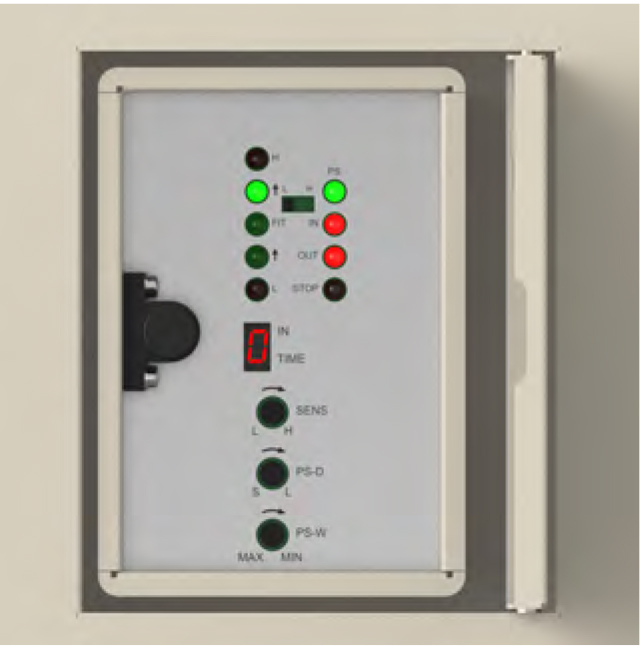

3. Visual weft detection: Visual adjustment function of weft detection sensitivity with independent intellectual property rights improves debugging efficiency.

4. Direct drive system: The permanent magnet direct drive system is adopted to greatly reduce the energy consumption and ensure the reliable and accurate operation of the equipment.

5. Full functional coverage: Four-spray pattern control technology, double warp beam electronic let-off and take-up,electronic dobby control and other functions.

Comparison between traditional textile electronic control system and VC600C series control system

VC600C is developed based on VEICHI's strong R&D and production capabilities, adopts a breakthrough integrated design concept, has stronger protection, higher integration, longer service life, solves many problems of traditional electronic control, and comprehensively improves water jet loom control level.

4 major defects of traditional electiccontrol cabinet

1. The protection grade of the cabinet is low, and the fan will bring the on-site steam and oil vapor into the cabinet, which will not only cause faults such as short circuit of the components in the cabinet, but also seriously reduce the service life of the equipment.

2. There are many wires and the wiring is messy, which is not only prone to interference, but also increases the fault easily.

3. The adjustment method of weft detection is complicated and backward, and the efficiency is very low. We need to open the chassis for each adjustment.

4. The volume of internal devices is large, which restricts future functional expansion.

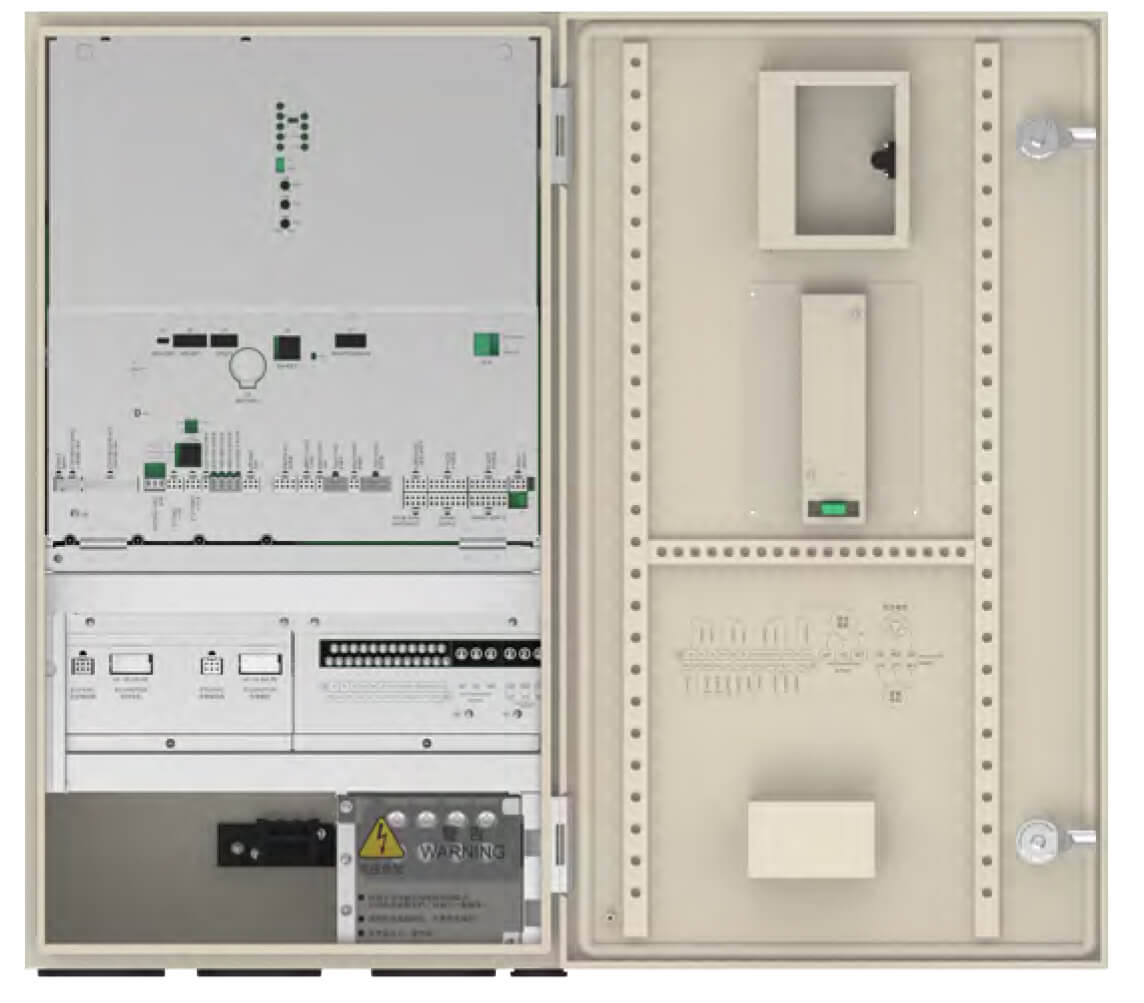

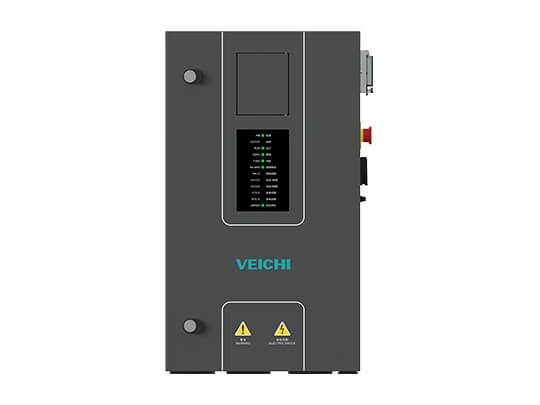

VC600C Cabinet Introduction

The IP54 protection level of the box(certification:20210505K12013), effectively isolates the steam and oil vapor on the weaving site,ensures the normal operation of the equipment,and improves the service life of the equipment;the whole workshop can be powered off for a long time during holidays.

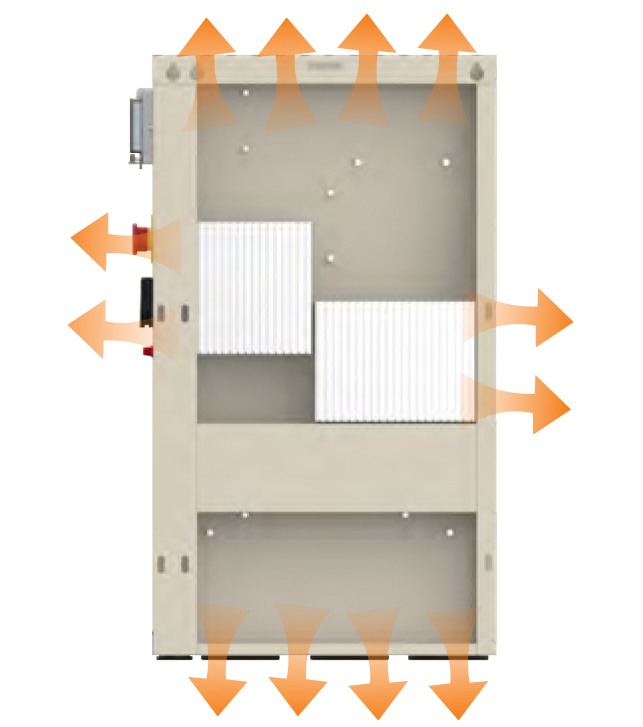

Fanless design

Solve the problems that the fan of the traditional textile control cabinet is easy to be damaged caused by water, oil accumulation and other problems, and prolong the life of the electronic control equipment.

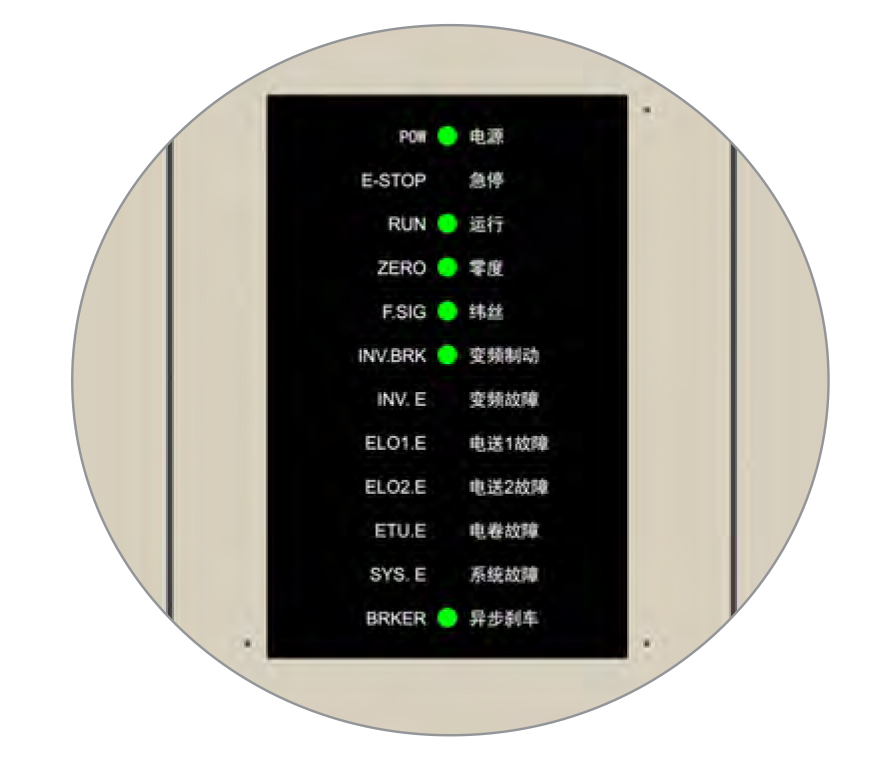

LED indicator

The running status of the loom is clear at a glance, making maintenance more targeted.

Back radiator

The air duct is designed on the back of the box, and the temperature in the cabinet is effectively reduced through the back radiator and the using life is improved.

Small size and high integration

The VC600C series directly eliminates the cost of the equipment manufacturer's chassis, is smaller in size, lighter in weight, and more convenient to install.

Visual weft detection(invention patent number: ZL2019 10889295.5)

The self-developed visual weft detection technology improves the traditional adjustment method of weft detection, and the adjustment of weft detection is more intuitive and faster; it has the self-learning function of weft detection, which can effectively prevent empty stops and missed stops.

VC600C series cabinet layout introduction

VC600C all-in-one machine relies on VEICHI's rich product lines, and adopts advanced modular design concept in the cabinet, which has a more reasonable layout, more convenient maintenance and stronger extensibility.

1. Easy maintenance: Just replace the corresponding control board.

2. More scalable: Equipment transformation, upgrade, only need to adjust the corresponding control panel.

3. Eliminate the wiring between units: Solve the problem of poor contact of wiring in high vibration environment.

4. Standard terminalless toroidal transformer: Lower temperature rise, no afraid of vibration, more stable operation.

5. Adopt common DC bus technology: Compared with traditional asynchronous motors and direct drives, it is more energy-saving.

Support process parameter copy: Machine parameter settings, process settings, parking gear compensation settings, etc. can be copied to another system with a USB flash drive, which is convenient and quick to set once.

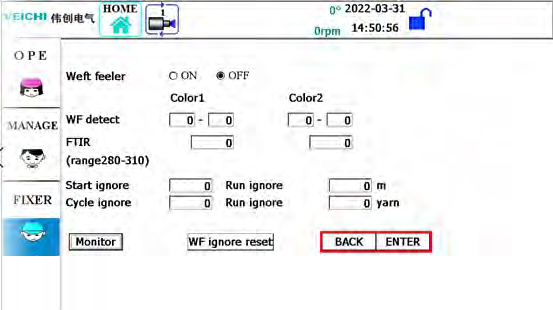

Introduction of VC600C series weft insertion control and digital weft detection

The problem of weft detection has always been a difficult problem for end customers. In order to solve this problem, VEICHI has adopted the dual weft detection technology of outer detection and inner detection on VC600C through years of painstaking research and development to escort the stable operation of the equipment.

1. Built-in digital weft detection technology, real-time display of weft detection waveform.

2. The sensitivity of each jetting weft yarn is independently set to solve the empty stop or the non-stop wefting caused by the large difference of the multi jet weft yarn.

3. External visual weft detection to solve the problem of difficult adjustment.

4. Support high-end weaving needs of four jets.

5. The real-time tracking adjustment algorithm of the main shaft is built in the pattern board, and the weft insertion control is more stable(magnetic needle, rotary valve, yarn gripper, etc.).

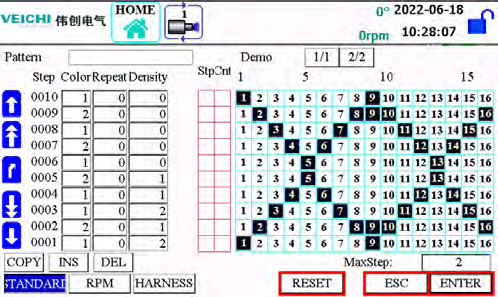

VC600C series built-in electronic dobby control introduction

1. The main control integrates electronic dobby control, supporting 16 pieces of brown frame.

2. The timing angle of the electronic dobby is controlled by the host encoder, which is more accurate than the original proximity switch control, and completely avoids the phenomenon of wrong flowers.

3. It supports pattern editing with 10,000 steps or more, supports the weave cycle of the fabric, supports empty beating-up, stop prying, and freely change the weft density.

4. It provides dual pattern editing environment on HMI and PC, and supports arbitrary switching, reading and storage of local master control and U disk.

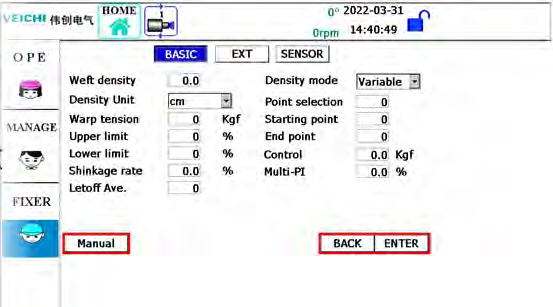

Introduction of VC600C series electronic let-off and take-up function

Electronic let-off and take-up system controlled by integrated main system

1. The main control integrates the advanced discrete tension PID control algorithm to make the tension converge quickly.

2. Supports 10,000-step pattern variable weft density settings, and the weft density of each shuttle can be freely and steplessly changed.

3. Supports rich functions such as left and right double warp beams, upper and lower double warp beams, and tension control of outof-machine winding.

4. Combined with the weave cycle of the fabric, the tension fluctuation under the complex weave pattern is within a reasonable range, and the hidden gear (for unbalanced weaving) is eliminated.

5. Built-in weaving fell swing, weaving fell avoidance, skid stop, weft compensation, time compensation and other new functions.

6. Rich maintenance navigation, the oscilloscope displays the tension curve and the let-off and take-up speed curve, which makes the human-computer interaction more in-depth.

VC600 Water Jet Weaving Electrical Control System Video

Industrial Applications for Weaving Direct Drive Electric Spindle System

Applications:Textile industry.

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|---|---|---|---|---|

| VC600C Electrical Control All-in-one Machine-appearance Design Patent Certificate | Certificate | Chinese | 2022-07-26 | 1.17MB |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message