Power-discharging Rack Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Power-discharging Rack Solution

The wire and cable industry is currently moving toward higher technological levels such as product diversification, automation, etc. The power-discharging rack is very common in the wire and cable industry and it can be divided into vertical stand-off rack and horizontal stand-off rack according to the style. The racks are all line-out devices, but they are different in structure. In the line-out process, the frequency inverter has become an indispensable device which can control the speed of the motor to achieve the line speed, thus improving the production efficiency of the process and ensuring process quality so as to maximize profit.

Features and Benefits

Introduction

In the line-out process, the frequency inverter has become an indispensable device which can control the speed of the motor to achieve the line speed, thus improving the production efficiency of the process and ensuring process quality so as to maximize profit.

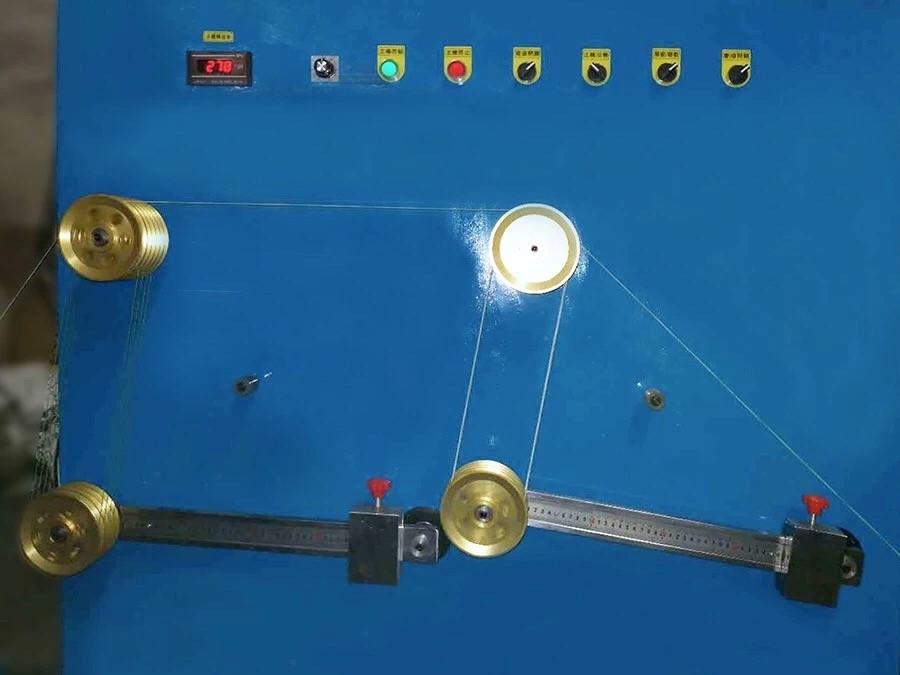

Power-discharging rack equipment working principle and composition

The power-discharging machine puts 2 lines (or multiple lines) and puts the wire through the balance bar machine. By judging the position of the balance bar, the pay-off machine is forward or reversed or stops at zero, and the line after the balance bar is finally into the stranding machine, the two strands (or multiple strands) are twisted together to finally realize the production. For example, we usually use the power-discharging rack to achieve production.

Power-discharging rack equipment functions

he power-discharging rack equipment must realize: The feedback lever can quickly and accurately find the zero point when starting the change; in the running, the power-discharging rack can be stably discharged; in the shutdown, the tension of the wire can be accurately ensured.

The following are the requirements for a power-discharging rack:

(1) When the pendulum rod is in the middle, the motor stops (commonly known as: zero position);

(2) The pendulum rod is below when the motor rotates reversely, and the maximum frequency does not exceed 5Hz;

(3) When the pendulum rod is at the top, the motor rotates forward, the maximum frequency is 30Hz, and the reaction time is faster;

(4) When the swing rod is up or down, it cannot touch the limit point;

(5) When the automatic zeroing point is reached, the swing amplitude cannot be too large, and the zero point can be quickly and accurately found;

(6) When the machine stops, the line will not be loose, or it will still be tight.

Application of AC300 on power-discharging rack

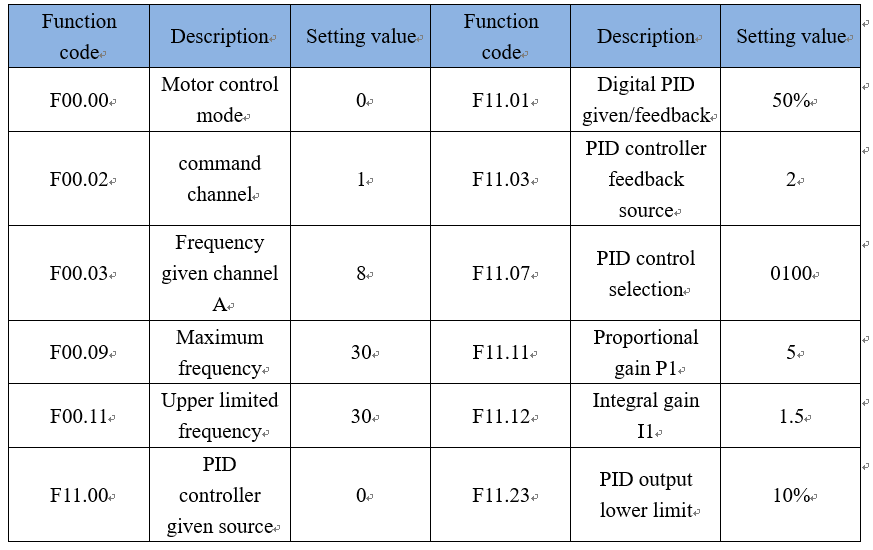

To achieve the above function of the power-discharging rack, the site uses AC300 frequency inverter PID function to achieve it, first find the feedback lever zero (physical position in the middle, this time the PID input can be set to 50%), the feedback lever access PID feedback, the positive or negative is achieved by offsetting the zero point of the feedback lever up or down, and other functions can be realized by adjusting the PID related parameters (PID gain, PID feedback, etc.).

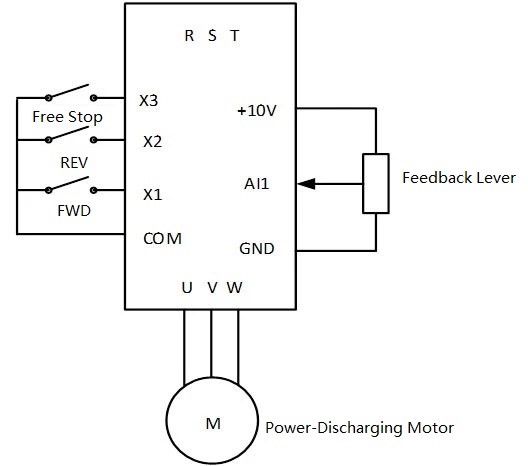

Frequency inverter wiring diagram is as follow:

AC300 frequency inverter parameter settings are as follows:

Summary

The use of drive pedestal is the PID control function of the frequency inverter. In the previous power-discharging rack, the AC80 drive was used to realize the power-discharging request. After the AC300 general-purpose frequency inverter was used, the power-discharging control was placed on the rack. The performance becomes perfect. The PID control algorithm is optimized on the AC300 general-purpose frequency inverter, which makes the PID control performance better, the accuracy is high, and the dynamic response is fast, so that excellent process control can be achieved and the reliability of the process control can be guaranteed.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message