Hexagonal Wire Mesh Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Hexagonal Wire Mesh Machine Solution

A hexagonal wire netting machine is professional equipment for producing regular hexagonal metal nets. It is widely used in petroleum, construction, breeding, chemical industry, heating pipelines, and other pipeline wrapping nets. It can also be used for fences, residential and landscaping protection, etc.

At the same time, the hexagonal net can also be used to make Shilong cages. It is widely used to protect and support seawalls, hillsides, roads and bridges, reservoirs, and other civil engineering. It is a good material for flood control and flood resistance.

Features and Benefits

Introduction

Hexagonal wire mesh, also known as twisted mesh, thermal insulation mesh, and soft-edged mesh, is woven from ductile low-carbon iron wire or PVC-coated iron wire. Its structure is firm, the surface is flat, and it has good anti-corrosion and anti-oxidation characteristics. It is widely used in aquaculture, construction, greening, decoration and other industries.

Hexagonal wire mesh

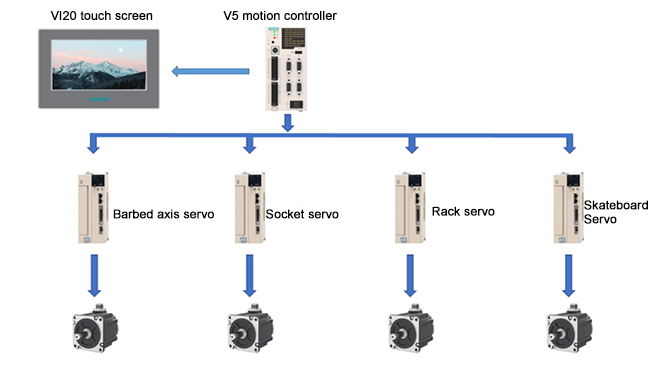

System topology

Hexagonal mesh weaving machine system solution, provided by VEICHI complete system, including touch screen, motion controller, servo driver and servo motor. Adopting the high-performance V5-MC104 motion controller of VEICHI as the upper control, communicate with HMI through RS422, realize the data interaction between HMI and controller, and output pulse to control the position of 4 servos. It not only improves the accuracy of equipment control, but also improves production efficiency.

Hexagonal mesh weaving machine system solution

Program highlights

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

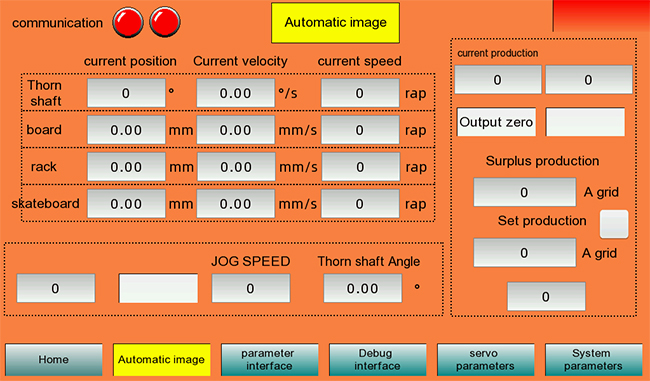

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. All parameters are displayed in real-time by the man-machine interface, and the net production and net speed can be preset, and the position of each station can also be adjusted by parameters.

4. The connection between the V5 controller and the servo uses a high-speed differential signal, which has high stability and is not susceptible to interference. The maximum pulse speed of the differential pulse port is 3M, which can achieve extremely high control accuracy.

Process principle

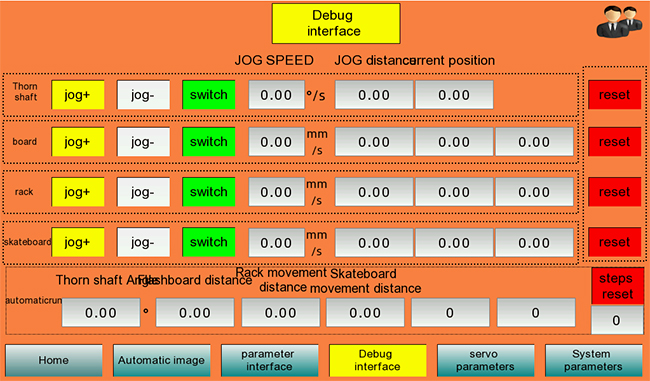

1. Barbed shaft: The barbed shaft is driven by the servo motor to pull the material upwards. The net hangs on the barbed shaft and moves forward with the rotation of the barbed shaft, pulling the wire upwards.

2. Skateboard axis: Driven by the servo motor, the iron wires are staggered left and right, and the two adjacent iron wires are alternately approached to prepare for the next step of screwing the net.

3. Board axis: Driven by the servo motor, the board is moved forward, and the screw wheel is driven to advance just to be inserted into the wire to be screwed so that the screw wire is in the middle of the gap in the screw wheel as if the wire is clamped by pliers.

4. Rack shaft: Driven by a servo motor, after the inserting plate shaft is in place, the rack moves to drive all the twisting wheels to rotate, and the iron wires clamped by each twisting wheel are twisted together.

Technical index

The servo pulse differential signal can reach up to 3MHz.

The running speed can reach 70-90 meshes/min.

Application

Hexagonal mesh weaving machines have undergone continuous technological innovation, and now they have greatly improved their production speed, quality and operation. The hexagonal net weaving machine system solution independently developed by VEICHI has been recognized by many users by virtue of its advantages such as high stability and strong anti-interference ability.

Hexagonal mesh weaving machine

Features

1. Stable performance, easy to operate and maintain

The whole machine adopts V5 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster; the man-machine interface is centrally controlled, stable performance, and easy to operate and maintain.

2. Real-time display of parameters, flexible setting

Real-time display of parameters, flexible setting

All parameters are displayed in real time by the man-machine interface, and the net production and net speed can be preset, and the position of each station can also be adjusted by parameters.

3. Strong anti-interference ability and high control precision

The connection between the V5 controller and the servo adopts a high-speed differential signal, which has high stability and is not susceptible to interference. The differential pulse port has a maximum pulse speed of 3M, which can achieve extremely high control accuracy.

Strong anti-interference ability and high control precision

The VEICHI hexagonal mesh weaving machine system can not only ensure the overall performance of the system, but also effectively improves the production efficiency, which can meet the all-round requirements of customers for the weaving system. Making products with meticulous craftsmanship, keeping improving and ensuring quality, has always been the development idea that VEICHI insists on. In the future, VEICHI will continue to intensively cultivate product quality, continue to innovate, and promote the high-quality development of the electric drive and industrial control industries.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message