Application of VEICHI AC100 in Oilfield Pumping Unit Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Application of VEICHI AC100 in Oilfield Pumping Unit Solution

Features and Benefits

1. Overview

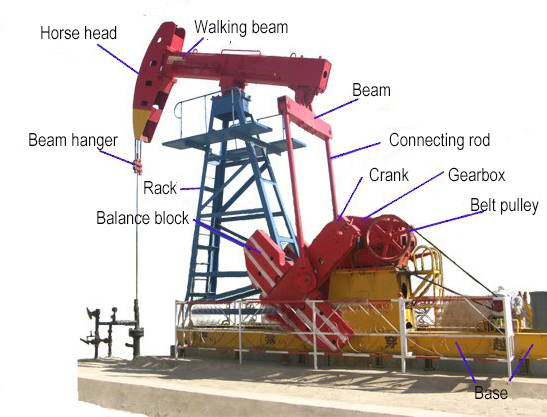

In China's oil-producing areas, there are a lot of complex fault block oil field with low porosity and low permeability. The beam pumping unit, commonly known as "kowtow machine", is widely used in these oil fields. The traditional pumping unit is driven by ordinary AC asynchronous motor. Because of its mechanical characteristics, the motor is always switching between the electric state and power state, and the switching frequency is high. When the motor is in the power state, it will feed back the excess energy to the power grid, causing the increase in the main circuit bus voltage which will reduce the quality of power supply; and the frequent impact will also cause damage to the motor, affecting production efficiency and increasing the maintenance cost of enterprises. In order to further improve the oil production efficiency, reduce maintenance cost and improve the digitalization, informatization and intelligence of pumping units, it is very important to develop new special drive for low pumping unit.

2. Working Principle

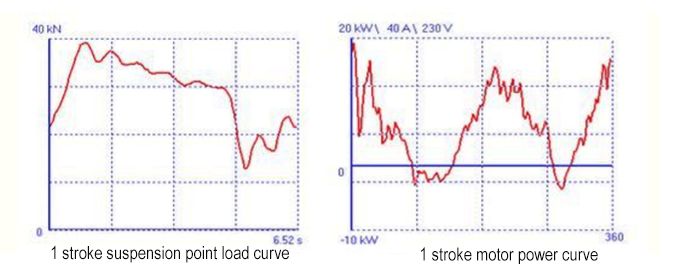

When the pumping unit is working, the load on the head of donkey is varying. On the upstroke, the sucker rod string moves upward with the plunger, and the swimming valve on plunger will be closed under the liquid column pressure. At this time, the pump pressure decreases, and the fixed valve will be opened under the effect of pressure difference between the annular space column pressure (sinking pressure) and the pump pressure. The pump inhales liquid and the wellhead discharges liquid. During down stroke, the plunger goes downward, and the fixed valve will be closed under the action of gravity. The pump pressure increases, when it is greater than the liquid column pressure above the plunger, the swimming valve will be opened and the liquid under the plunger will enter above the plunger through the swimming valve, which makes the pump discharge liquid and the oil pumping rod string do work on motor, so that the motor will be running in generator state.

It shows: when the pumping unit is of unbalanced output, the load of upstroke and downstroke is uneven which will seriously affect the lifespan and working efficiency of the pumping rod linkage, gearbox and motor, and it will deteriorate the working environment of sucker rod and increase its breakage times. Therefore, the main transformation of the whole oil pumping unit focuses on the motor output adjustment. After transformation, the motor will can adjust the output according to different work situations so as to reduce power consumption, reduce the impact on power grid, besides, the oil pumping unit will have strong networking capabilities to facilitate remote monitoring and maintenance.

3. The Solution of VEICHI

According to the characteristics of Chinese oilfield distribution and the working conditions of the pumping unit, the driving components of control system are VEICHI AC100 series vector control inverter.

Compared to the traditional oil pumping unit's frequency control system, out AC100 series frequency inverters are specially optimized for the oil industry:

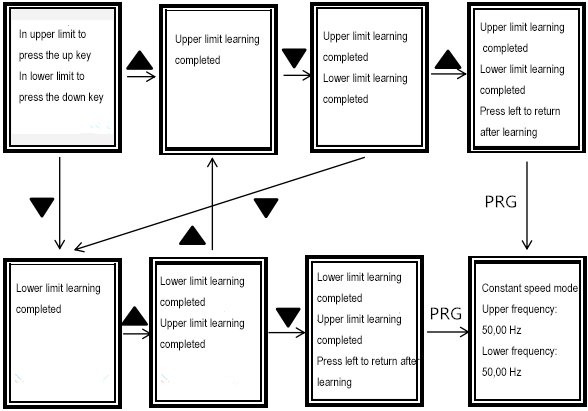

a. Set stroke self-learning function. Its function descriptions are as follows:

When entering the stroke modification interface, it only needs one self-learning to get the stroke range.

b. The stroke self-learning function of no proximity switch or proximity switch damage. Its function descriptions are as follows:

When there is no proximity switch or proximity switch failure, the oil pumping unit can continue running in a short time by the manual self-learning mode.

c. Increase the electrical parameter interface. Its function descriptions are as follows:

It can display the current balance, power balance, average power balance and other related electrical parameters, to facilitate the customers to assess the energy efficiency of pumping units.

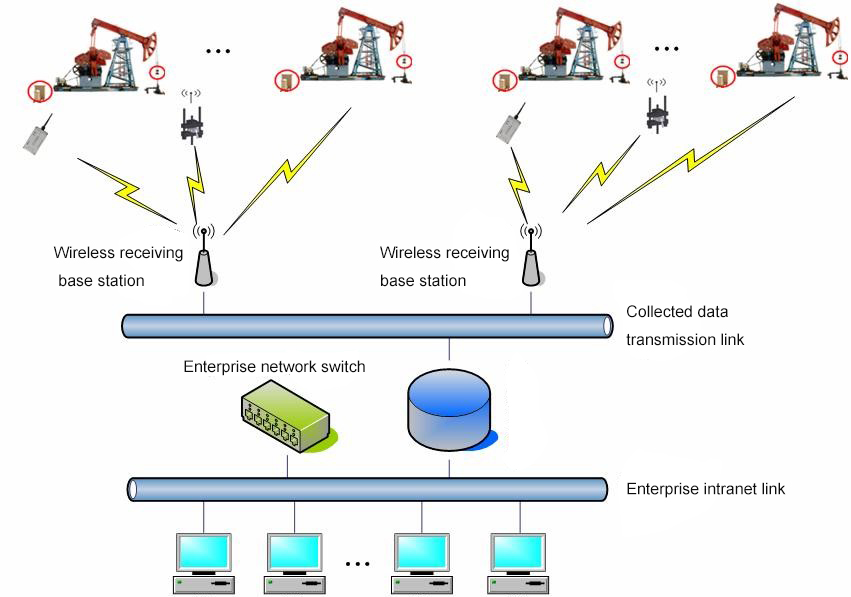

d. Rich communication expansion capabilities to facilitate the remote management, maintenance and pumping oil data collection. The CANOPEN communication module, wireless GPS module and more are optional to VEICHI AC100 controller so that you can select these items according to your actual situation.

4. Conclusion

As the operation of AC100 is simple and various parameter self-learning functions can be done within a click, so it greatly reduces the learning costs of operators on site. The powerful networking capabilities can enable you to achieve remote operation, which provides the possibility of unmanned, intelligent and informative oil production.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message