Frequency Conversion and Energy Saving Solution for Boiler Combustion System Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Frequency Conversion and Energy Saving Solution for Boiler Combustion System Solution

Features and Benefits

1. Basic Information

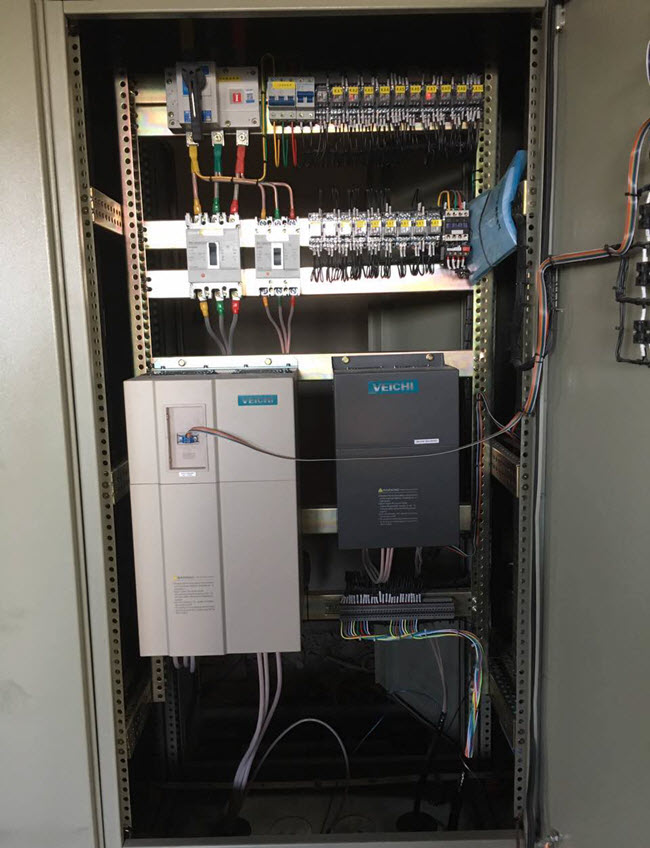

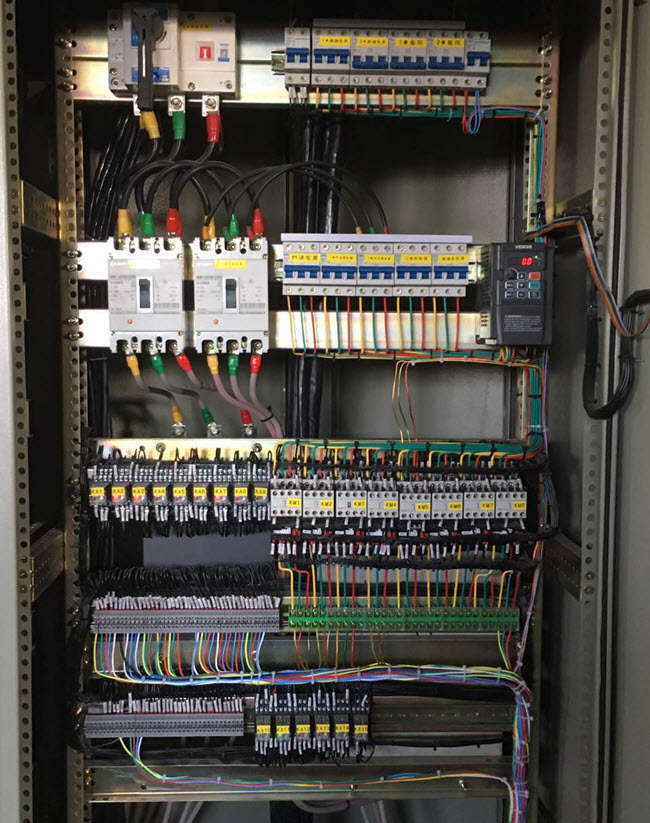

The factory adopts chain boiler as equipment steam boiler with 72KW introduced draft fan motor, 55KW blower motor and 5.5KW fire grate motor. The fire grate motor adopts DC speed regulation to adjust the amount of coal feeding and the blast and air flow are achieved by adjusting the air door. The blower motor and introduced fan motor uses reduced voltage starting mode.

2. Analysis on the Operation Condition of Boiler Air System

a. Poor adaptability to load change in manufacturing process

As the production load and climate are constantly changing, the boiler system is required to follow its changes. The existing coal feeder in combustion system adopts DC regulation, in which the coal feeding amount is in direct proportional to the rotating speed. Air flow is adjusted by air door, but the opening size is not in direct proportional with air flow adjustment, in result, the ratio of air flow and coal amount can’t adapt to load changes.

b. The existing air supply system can not meet the requirements of boiler operation process.

Air flow can be reduced by adjusting the air door, but the air pressure will be increased. In order to prevent wind into the furnace caused by blown out coal seam, the coal seam must be thick, as a result, the coal consumption will be increased because of insufficient burning.

c. Serious energy waste

Generally speaking, the inconvenient air door adjustment will result in over-supply in air blowing and air taking system. Excessive air supply(40℃) will absorb a lot of heat into the furnace(500℃ above) and lead to coal waste, at the same time, the high motor current will result in energy waste. Conversely, the over amount of introduced air will take a lot of hot air away. Although after the economizer, the exhaust gas temperature still exceeds standards and causes coal waste. If the fan motor current is up to the rated value, the electricity is wasted.

d. Power grid impact caused by motor start

Although the motor start adopts reduced voltage mode, the staring current is still up to 3-4 times of the rated current in starting process, and has complex operation, large maintenance work and more costs causing by high equipment failure rate.

3. Frequency Conversion of Air Supply System - Must Trend to Reach Energy Saving Target and High Heat Efficiency

A. Incomparable superiorities of frequency conversion.

a. Outstanding energy saving effect

According to the characteristics of the centrifugal fan, the fan flow change is in direct proportional to the rotating speed, same as the power and the cube of rating speed. Therefore, when the load is adjusted, the rotational speed is changed, so that the shaft power is obviously decreased, achieving remarkable energy saving effect.

b. Fully meet the process requirements.

The proportion of air flow and speed together with the adjustable air flow and air pressure can fully satisfy the process requirements of air regulation in combustion system, which can greatly decrease the amount of fly ash, improve heat exchange efficiency, reduce environmental pollution and save coal consumption.

B. The fan efficiency is calculated by the following equation: ηp=C1(Q/n)-C2(Q/n)2

Q stands for air flow, n is for rotating speed and C1C2 is constant.

When the air flow is adjusted by air door, the rotating speed n is still but air flow Q is reduced, so the efficiency np is reduced; when the air flow is adjusted by rotating speed, they are in proportional rate and the ratio Q/n keeps still, so the efficiency np is always in best condition. Therefore, after adopting frequency conversion, the fan’s working efficiency is greatly increased.

4. Economic Benefit Analysis

A. Save electric charge.

When the 75KW introduced fan and 55KW blower is working at 40Hz, its working speed is 80% of the rated speed and fan’s consumption power is P2=0.83Pn=0.512Pn. If puts the production period as 12 months and considers the total energy saving rate is 30%,

W=(75KW+55KW+5.5KW)×12×30×24×30%=351216KW.h. If the unit price of electric charge is 0.5 RMB/KW, the annual charge can be saved is 351216×0.5=175608RMB.

B. Save coal consumption.

The convenient combination of air flow and coal rate can well adapt to load change to reach the best burning way,increasing heat efficiency. In the case of producing equal amounts of steam, the annual coal consumption can be saved 5%. If we take the daily saved coal consumption as 60T and the unit price as 200RMB/T, more than 60×5%×200×30×12=216000RMB can be saved.

After frequency conversion, the direct economic benefits reached in one year is 175608+216000=391608RMB.

5. Equipment Investment

| Product | Model | Quantity | KW |

| frequency inverter | AC70-T3-075G/093P |

1 pcs |

75KW |

| Frequency inverter | AC70-T3-55G/75P | 1 pcs | 55KW |

The total charge for the frequency inverter and its parts, operation, maintenance, installation and debugging is 139608RMB.

The general service life for a frequency inverter is 5 years, and the investment return is calculated as below:

The saved electric charge for 75KW is: 75×24×30%×0.5=270RMB.

The saved electric charge for 55KW is: 55×24×30%×0.5=198RMB.

The investment return is 139608÷(270+198)÷30=9.9month.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message