Practical Application of Veichi S200 on Construction Elevator Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Practical Application of Veichi S200 on Construction Elevator Solution

Features and Benefits

With the development of construction industry and the raising construction mechanization level, it has higher requirements in construction lifting. The working performance of construction elevator directly influences the schedule of construction.

Part 1. Disadvantages of Traditional Construction Elevators

As traditional construction lift adopts contactor- relay output mode, direct start and mechanical brake force start, the inertia and force brake brings large shock to mechanical structure, causing poor comfort and items dropping in the elevator. It affects the construction speed, efficiency as well as security.

Part 2. Great Benefits of Applying VFD to Control Construction Elevator

There are many advantages of adopting Veichi construction elevator control system on the construction elevator: zero speed brake with no wear and tear; arbitrary place speed with high leveling accuracy; speed smooth transition with no shock to structure and components; arbitrary wide adjustable speed range with improved working efficiency. Owing to these obvious advantages, Veichi S200 has been widely used in construction hoist field that it's of important significance to its secure running.

Part 3. Structure of Construction Elevator

Construction elevator has already become indispensable vertical transportation equipment in modern high-rise building construction process that it plays an irreplaceable role in ensuring construction schedule and safety, reducing construction costs and labor intensity.

The main components of construction elevator are as follows: guiding track framework, suspension coop, transmission system, framework adhering to wall, chassis guardrail, electrical system, security devices, power supply devices and more.

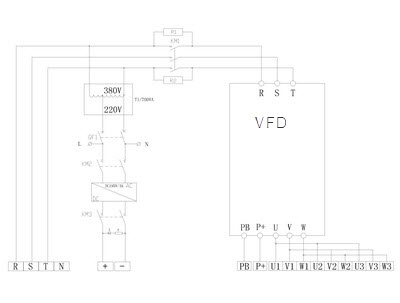

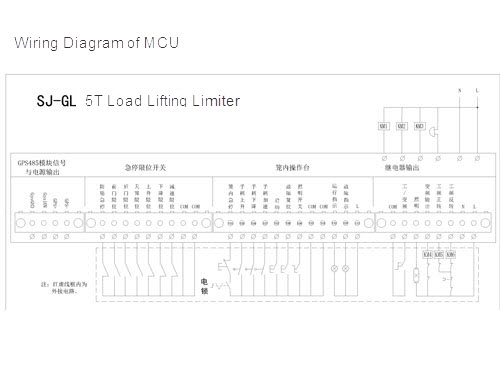

Part 4. Wiring Diagram

Part 5. System Debugging of Construction Elevator

1. Debugging of 4.1 frequency conversion system

In the case of ensuring the main circuit and control circuit is of correct wiring, please start debugging the system. Set the parameters of motor via the operator panel on SD200. Afterwards, please start no-load debugging, rated-load debugging and overloading debugging according to the international construction hoist testing rules.

2. Security debugging of 4.2 Construction Elevator

Safety is the most important standard for construction elevator, so the system debugging should be strictly tested in accordance with the national safety standard. During the no-load debugging process, please test whether the up and down limit switch and the limit switch of each suspension coop's door are taken standard actions according to the design. Under the overload condition, please start overload debugging test. The anti-falling test usually requires installing anti-falling security device on the construction elevator. Anti-dropping security device is an important component of construction elevator that it can eliminate suspension coop falling accidents. The anti-drop test of construction elevator must be conducted every 3 months in order to guarantee the safety. The drop test can be done following these steps: open the motor brake, let the suspension coop drop on its own weight at the simulated fall speed, meanwhile, please check whether the anti-dropping security device is working or not.

Part 6. Summary

The practical debugging result indicates that the Veichi S200 construction elevator control system is of complete protection functions, easy debugging, zero shock and drop, and high stability. It effectively reduces the shock to reduction, coupling and other mechanical components, reduces the impact to power grid, simplifies the system maintenance, and improves the working efficiency of construction elevator. Therefore, there's a good application value of using Veichi S200 in the construction elevator system.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message