Application of Veichi AC60Q on Ball Milling Machine Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Related Cases

- Related News & Events

- Related Solutions

- Contact us

Application of Veichi AC60Q on Ball Milling Machine Solution

Features and Benefits

1. Preface

For a long time, the ball milling machine has been commonly used in chemical, cement line and ceramic industry for grinding material. Usually, the ball milling machine adopts the frequency sensitive variable resistance starting mode, easy to cause the material of excessively grinded, long grinding period, low grinding efficiency, high power consumption per unit product, high starting current, big impact to power grid and equipments and troublesome maintenance in electrical equipments (as the carbon brush, sliding ring, ball pulled fork and dynamic and static contact of contactor need to be replaced or maintained at intervals). It is not only a headache to electric engineers, but also seriously affecting the production. In the case of low power grid, the ball milling machine even cannot start. Besides, the electricity consumption is exceedingly high.

This will cause a lot of unnecessary trouble and serious resource waste, so with the development of social economy and expansion production scale of enterprises, the drawbacks of ball milling machine control mode are directly exposed and severely hinder the rapid development of industrial enterprises. These are the main reasons why Veichi AC70Q comes into the world.

2. Main Components of Ball Milling Machine

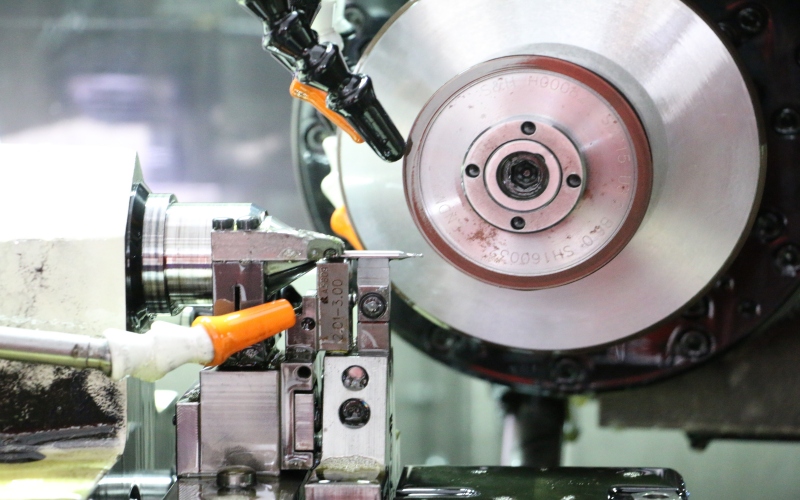

The ball milling machine is mainly composed of actuator, cylinder device, feeding device, discharge device and electrical control devices.

3. Working Principle of Ball Milling Machine

Ball milling machine is composed of feeding, discharging, rotary part, transmission part (reducer, small transmission gear, motor, electric control) and more parts. In ceramic industry, there is a horizontal cylinder which is divided into 2 to 4 grinding chamber by clapboard, each grinding chamber is equipped with a certain shape size grinding media. When the cylinder rotates, material and grinding media are ascending to a certain height under the friction force and centrifugal force, and then falling in the approximate parabolic trajectory under the heavy force to strike and grind another part of the material on the bottom of the grinding cylinder, meanwhile, a certain amount of axial movement prompts the material to be grinded and mixed evenly. It can be classified into two kinds according to the technique: dry milling and wet milling.

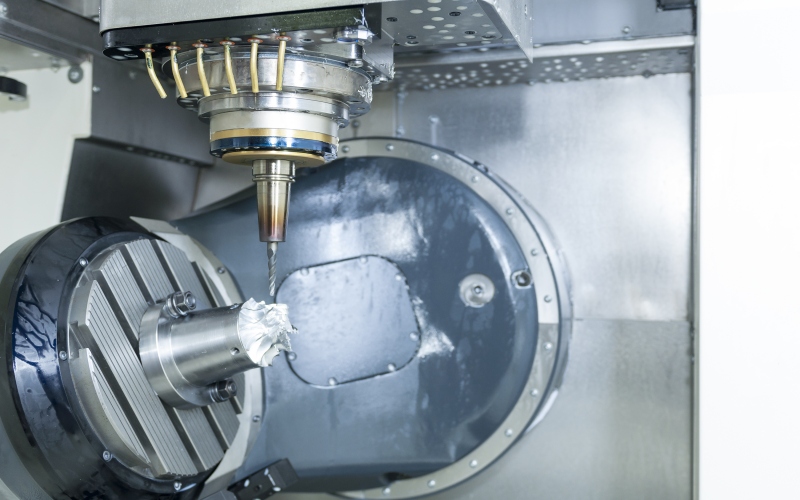

4. Basic Electric Control Device

Most of the ball milling machines adopt frequency sensitive rheostat as the starter (its volume size is much smaller than the resistance box and it achieves speed control purpose via step-by-step short resistance). At the starting moment, there is large impact to the power grid, after the starting moment, the required torque is reduced, therefore, there is a large energy saving space.

5. Retrofit Scheme

According to the existing problems and production technique requirements, the transformed ball milling system can meet the following requirements:

a. The transformed equipment has enough starting torque, meeting the large loading requirements of ball milling machine and ensuring the motor run stably in variable frequency status with constant power characteristic.

b. By using the variable frequency speed control system to transform the original ball mill drive system, it should ensure the ball milling machine work normally at low speed and ensure the normal process control. It is without saying that the life span of ball milling machine and motor will be increased and the maintenance cost will be reduced also.

c. The transformed equipment should achieve automatic control, manual control and power frequency control. It requires automatic fault switch function. Besides, it should be capable of overcoming the large inertia and recovery voltage of ball milling machine and ensuring the normal operation of equipment.

6. variable frequency drive Model

Veichi AC60-T3-###QK series ball milling machine inverter can meet the above application requirements.

7. Characteristics of Veichi AC60Q

a. It meets the requirements such as low speed running, large starting torque and constant yet adjustable speed requirements of ball milling machine. No surge current at the moment when motor starts, enough starting torque and perfect protection function, Veichi AC60Q ensures the process quality control and reduces the system maintenance cost.

b. It has hundreds of ball milling machine transformation experience and suits the V/F performance characteristics. Facts show the transformed system work more stably and efficiently.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message